Introducing the Production system

High-speed metal 3D printing for mass production

Excellent part quality

High-resolution 3D printing and a uniform print bed allow the Production System™ to produce fully-dense, high-quality parts capable of performing in the most demanding applications.

- High-resolution printing

- Uniform print bed

- Fully dense parts

Competitive cost per part

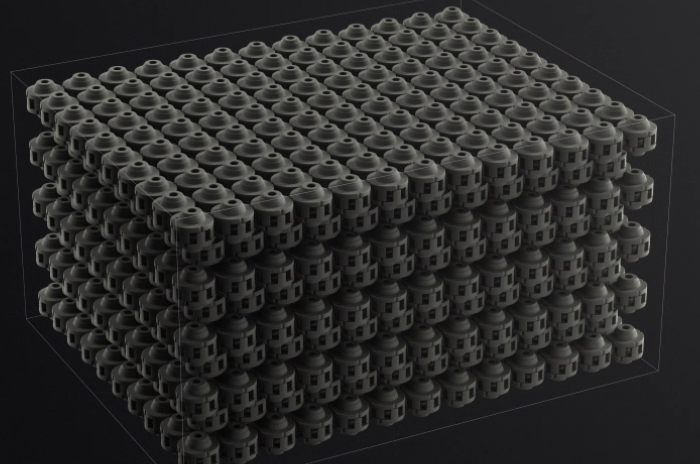

Deliver per-part costs competitive with traditional mass production techniques through the use of low-cost metal injection molding (MIM) powders, high-speed 3D printing and the ability to densely nest many parts in a single build.

- Low-cost MIM powders

- High-speed printing

- Dense 3D nesting

Best in class repeatability

The Production System™ offers robust repeatability, through anti-ballistics technology, print bar redundancy and live optical print bed inspection. Meaning you can print with confidence.

- Print reliability

- Print bar redundancy

- Real-time print bed inspection

Wide material compatibility

The inert environment, open material platform, and selection of Desktop Metal-engineered binders enable the Production System™ to 3D print with a wide variety of metals—including everything from stainless steel to reactive metals such as titanium and other high-performance alloys.

- Inert, closed powder environment

- Open material platform

- Desktop Metal-engineered binders

Powered by Single Pass Jetting

The Production system is based on a new approach to metal 3D printing—Single Pass Jetting (SPJ). Created by the inventors of the binder jetting and the single pass inkjet processes, Single Pass Jetting builds metal parts in a matter of minutes instead of hours.