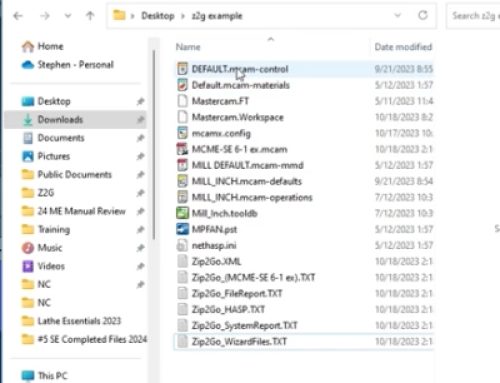

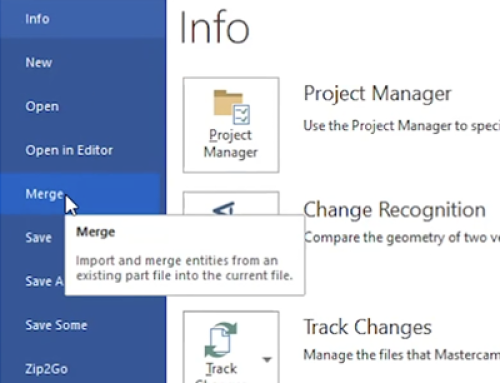

If you know Mastercam you know Mastercam Productivity +. Probing operations are created easily using the Mastercam interface by selecting geometry for inspection. You can also incorporate standard tool detection operations for long run jobs. Working with Mastercam Productivity + you can run the program two ways. Post all the Productivity + code with your NC code and keep it as a self contained file or you can post the NC code with the macro calls, saving space on your memory. My experience is to use the macro calls. Some people might question what happens if your memory gets erased. If you’re not backing up your control setting and you lose your memory you have bigger problems then probing routines!

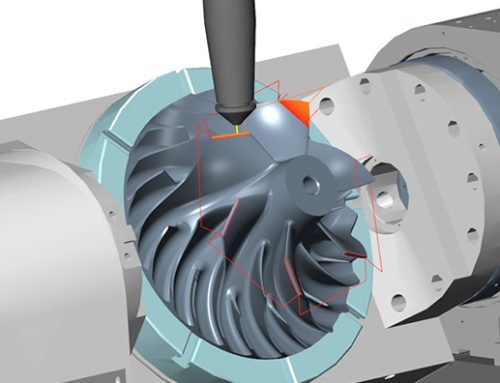

Probing is the method of measuring the physical geometrical characteristics of a CNC machine or machined part in a X,Y & Z motion, capturing that data, and translating it to the CNC machine for offset information or part geometry inspection. It enables programmers and machinists to establish best practices for maximizing the efficiency, quality, capability and accuracy of machine tools. Many modern CNC machine tools have standard routines built into the CNC controls to simplify the integration of probing cycles into machining operations and offline tools. These routines, combined with a CAD interface like Mastercam Productivity +, makes the simulation of measurement functions easy.

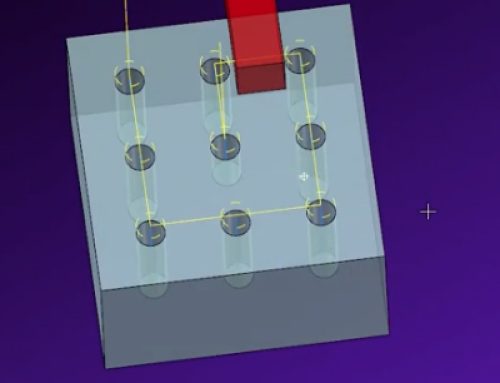

Mastercam Productivity+ is an Add-On to Mastercam CAD/CAM software that allows you to program using the well known Mastercam interface to program and simulate a Renishaw probe for your machine tool. Renishaw is one of the world’s leading engineering and scientific technology companies, with expertise in precision and process control products for a wide range of applications and industries. Mastercam Productivity + is used for tool and part setup and in-process inspection. It uses a measuring probe via a Mastercam probe operation (on a machine tool) to determine fixture offsets, orientation, and critical dimensions.

As the Productivity+ program runs entirely on the machine tool, the program forms a self-contained package, which operates in exactly the same way every time a part is run. Once it’s programmed there is no need for an external PC, eliminating potential communications set-up issues. Machine tools including 3-, 4-, and 5-axis configurations are supported via a wide range of post processors providing a consistent level of functionality between machine types. This makes it possible to transfer one probing program between machine tools by simple reposting the program.

Key Features

- Predictive process setting – performing simple tests to ensure that a machine process will be successful.

- Active in-process control – using the probe to measure features and update machining process based on the results obtained.

- Informative reporting – providing information about the in-process state of a component, and about the decisions that were made when producing it.

- Productivity+ creates programs that run entirely on the machine tool, including all the calculations, updates, and logic that are needed.

- No external PC is required to process measurement data.

Probing operations require an additional processing step before they are posted to your machine. This additional processing incorporates instructions for the selected Renishaw machine file (.RenMF) and is initiated form the Probing Post Tool dialog box which displays after you accept the settings in Mastercam’s standard Post Processing dialog box.

Using Mastercam Productivity + to off-line program your on-machine probing offers a number of advantages.

Save time. Reduce scrap.

For long run jobs that are unattended, in-process tool checking and gauging tackles variations that are inherent to machining, such as tool wear and temperature variation. This provides intelligent feedback to the process and decision-making as machining progresses. These are active controls that are applied during metal cutting. You would need a modern CNC machine tool to accomplish this.

Broken tool detection recognizes the following:

- Presence of a tool

- Tool position – to ensure pull-out has not occurred

- Broken and/or chipped tool edges

In-process gauging allows the following:

- Metal cutting to adapt to variations in the machining process, such as part distortion, tool deflection, and thermal effects

- Updating of co-ordinate systems, parameters, offsets, and logical program flow depending on actual material conditions

Tool setting for accurate tool lengths and diameters saves machine setup time and gets parts done faster. Probing routines can speed setups by establishing the exact location of a workpiece fixtured on a machine so the part program can be aligned to it. With more consistent parts off the machine, probing makes machining better from start to finish and as any machinist can tell you, if you start on the right foot you finish with a good product.

To take advantage of Mastercam Productivity+, you must have Renishaw probe installed on your CNC machine tool and at least Mastercam Mill. To learn more about the Mastercam products, please click the button below.

Leave A Comment