Built-Rite Tool & Die, a Cimquest customer, is a mold-making and design firm based in Lancaster, MA. The company makes precision molds for use in a range of injection molding techniques.

The Desktop Metal Studio System has been tested by Built-Rite for the manufacture of several components of the Studio System metal 3D printer. These included a “flipper arm” used in the Studio System to “eject the bound metal or interface media rods into the extruder where they are heated and deposited onto the build plate, shaping a green part.”

Ron Caron, General Manager at Built-Rite, commented that “Molds must be built to withstand very high pressures. The printed inserts that we prototyped for Desktop Metal were able to pass the first round of tests and successfully molded several parts. In the beginning, we immediately saw some of the advantages of using metal printed components in our molds.”

According to Caron using 3D printing allows the inserts to be produced in a quicker time, given that production could be brought in-house. Also, it was possible to design cooling channels in a new way. One benefit here was a weight saving and subsequent reduction in operator fatigue.

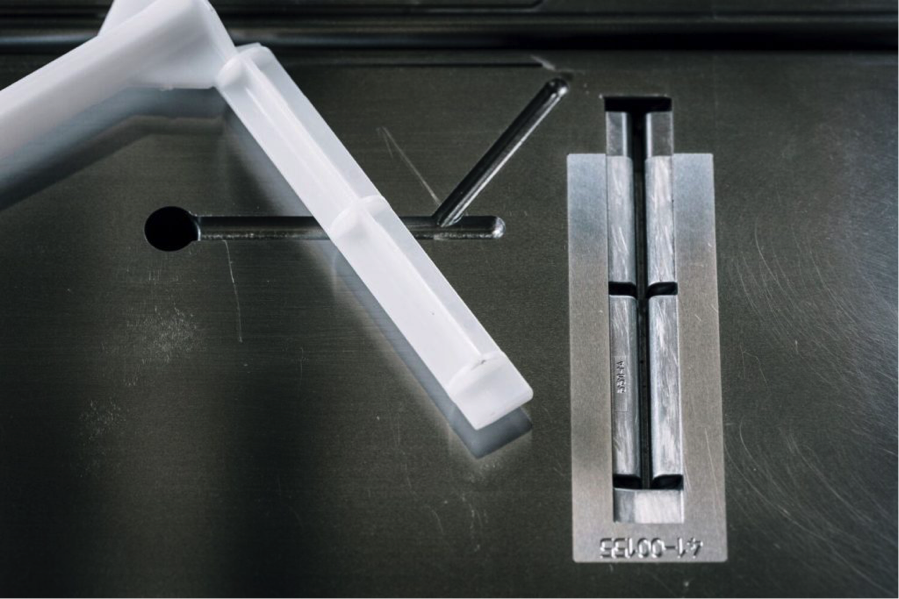

The injection mold insert. Photo via Built-Rite.

The total cost of the Desktop Metal Studio System is $120,000. The full package includes the DM Studio Printer (additional Printers can be added for $49,900 + tax), a DM Studio Debinder (additional Debinders $9,900 + tax) and the DM Studio Furnace (add additional Furnaces for $59,900 + tax).

This confirmation of shipping ends a great year for the company. In May, 3D Printing Industry readers voted for Desktop Metal as the start-up of the year. An accolade that was only surpassed in July when the Burlington based enterprise achieved unicorn status with a successful series D finance round.

As work continues on the company’s second 3D printing solution, the Desktop Metal Production System, having reached this important milestone is a great way to end the year.

Download the case study by clicking the button below.

Oh wow, 3D injection, if can fully utilize metal as a material, will truly be a disruptive technology and can make the construction industry as effective as ever. I hope this company completes their innovation. It is truly a milestone for them and the industry.