For a small shop or even an individual taking their first step into CNC machining, the initial cost is one of the most important factors in decision-making. When that decision is which CNC machining unit to buy – a milling machine or a lathe – it pays to know which one will be more profitable in the long run.

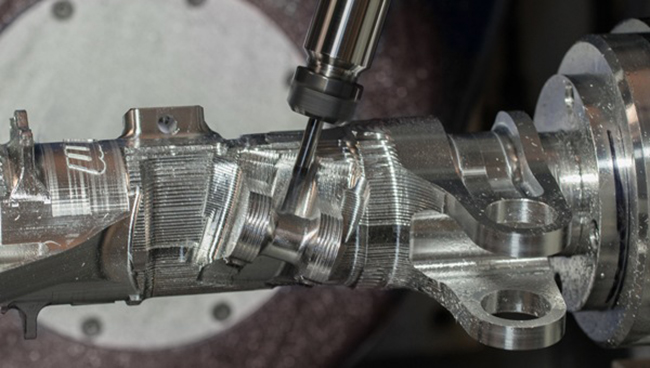

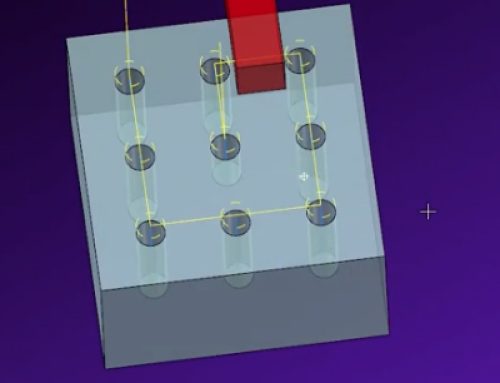

What is milling?

Milling is a type of subtractive manufacturing, which means it removes material from a block to “reveal” the part underneath. In a CNC milling machine, the stock material is held still by fixtures within the central part of the unit. A cutting tool, which rotates at very high speeds, then moves into the material to cut the material away. In some units, the stationary material moves towards the spinning tool, but the idea is the same. Milling can shape surfaces as well as drill holes and pockets.

When should you use a milling machine?

Milling machines are essentially the jack-of-all-trades in the machining world. They may not be the best choice for highly specialized applications, but they can do most of the work on most parts that come through the average shop. Shops that produce basic engine parts, industrial components, and molds for plastic injection molding might only ever need a good CNC milling center. Most shops, regardless of industry, will probably have at least one CNC mill.

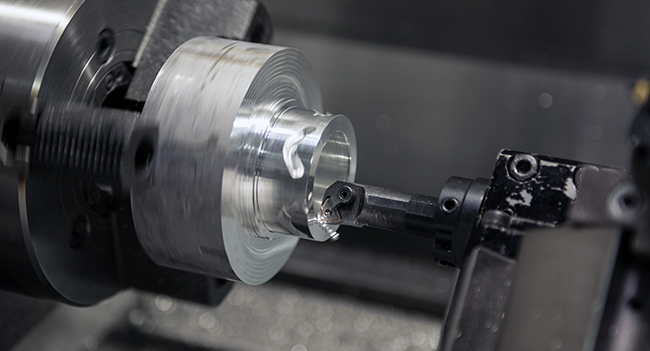

What is turning?

Turning is also subtractive manufacturing, but instead of a spinning cutting tool advancing into a stationary block of material, the material itself spins. Most people are more familiar with wood lathes, like the machines with which wooden spindles are made. The concept is the same with metal. Lathes spin the material quickly while the cutting tool moves into the stock. Threads of metal are chiseled off to specific depths as the material spins until the part is complete.

When should you use a lathe?

Lathes excel with parts that have rotational symmetry. This makes sense when considering how lathes work; if the object is spinning on one axis with a tool cutting its exterior, symmetry makes the whole process work. Some of the most commonly turned parts are components like screws, rods, and spherical objects.

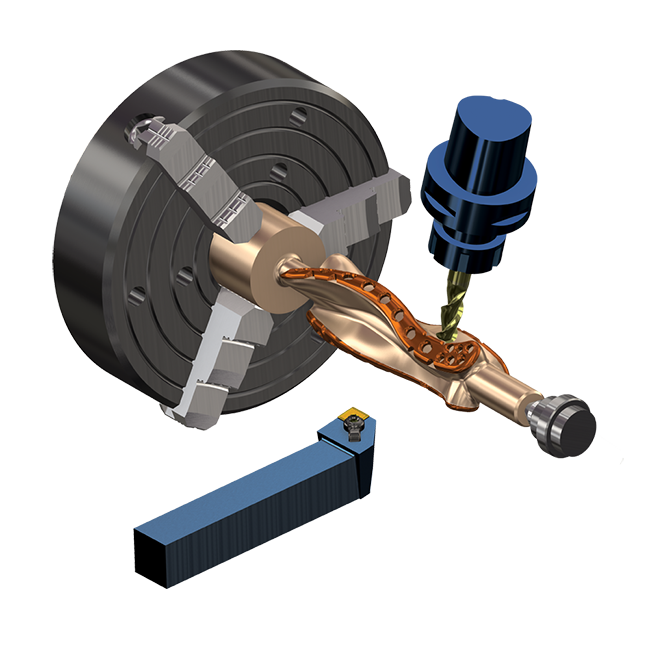

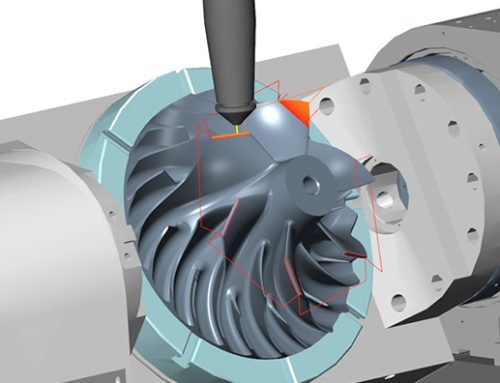

What about mill-turn?

Some machines combine the best of both worlds. These are referred to as mill-turn units, and they can do almost everything a milling or lathe unit can. If a part would traditionally be produced by starting on either a mill or a lathe and then moving to the other (and possibly back again), it makes more financial sense to simply use a mill-turn machine.

Leave A Comment