Machine simulation creates a virtual representation of a CAM program that mirrors exactly what will happen on the CNC machine. Basically, it creates a model of the cutting process that you can follow in real-time. It shows the workpiece, tools, and fixtures as well as how they interact with each other, highlighting any points at which a mistake will be made. This blog will walk you through the three biggest benefits of using machine simulation when you program your CNC parts.

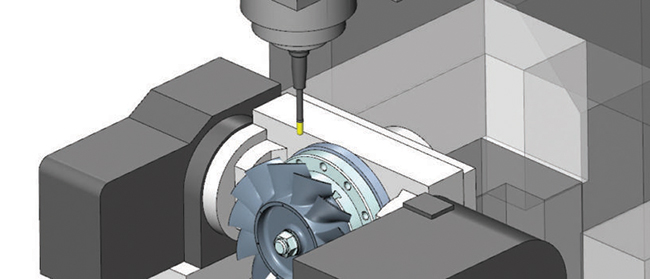

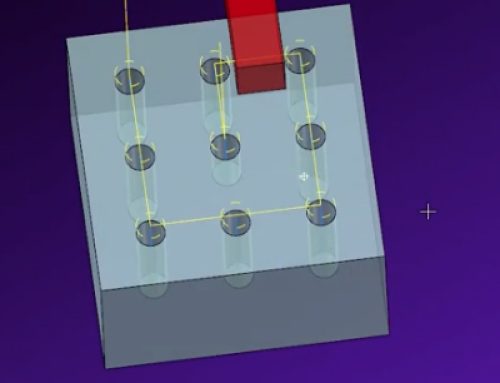

Experiment with different manufacturing strategies to find the most efficient process

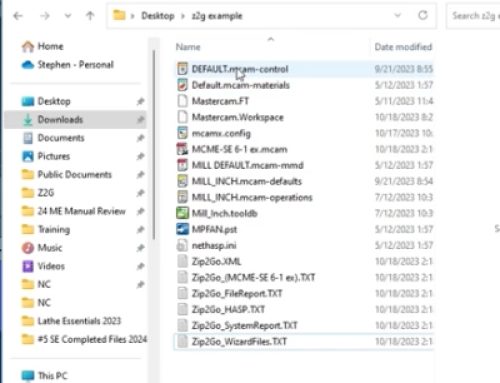

With machine simulation, there is no need to tie up a machine or waste material doing prove-outs. Users can determine which machining approach results in the fastest, highest quality parts just by clicking a few buttons.

The first thing programmers should analyze in their simulation is their fixturing. Is there any redundancy? Is this option the best one available for this particular part? Is there a way to change the fixturing so that one or multiple setups are eliminated?

After they decide on a fixture, they can then break down their code. In almost any program, there is room for improvement. Often, multiple toolpaths can be rolled into one. Consider Dynamic OptiRough. It replaces multiple roughing approaches by optimizing feeds, speeds, and angles to remove the most material quickly and safely. Sometimes a completely new machining strategy is called for. For a part that requires a long list of setups, a programmer can play around with 3+2 machining. This approach is a stepping-stone to multiaxis machining and can cut cycle times dramatically. In any case, the user is able to create and apply new approaches – no matter how wild – and see exactly how they will play out without endangering anything.

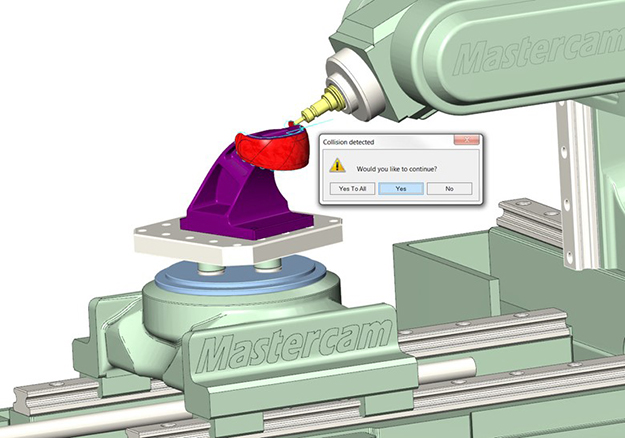

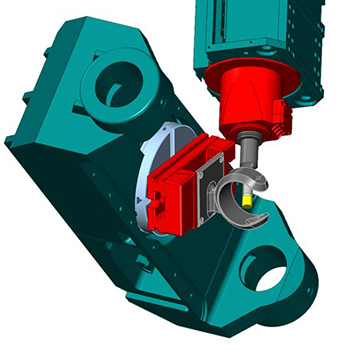

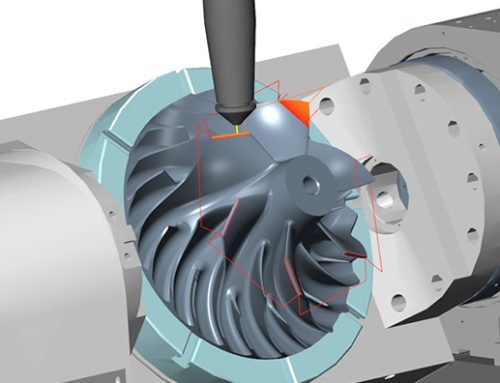

Detect collisions between your stock, tool, and machine components

Mastercam Simulation features analyze stock material, heads, turrets, tables, spindles, cutting tools, tool changers, and fixtures during every step of the planned machining. It takes all of the carefully curated data on each component and uses it to precisely map where every single one will be. By now, you know how important it is to avoid machine crashes. But this Simulation package takes it a step further by also checking for collisions to the stock and fixturing components. Even a part with the loosest of tolerances is useless if a huge gouge is taken out of it during machining due to a programming error.

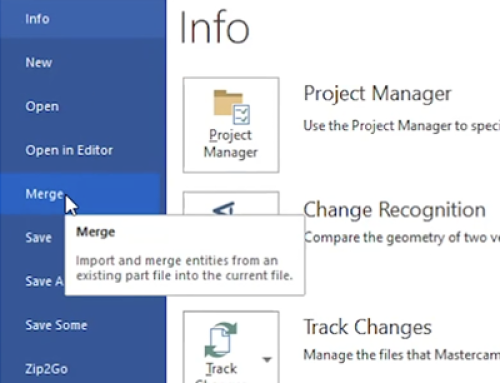

Find errors in your code, not at the machine

So much time and effort is devoted to optimizing programming, reducing tool wear, and keeping machines calibrated. But the truth is that all this work is for nothing if the machine crashes. When something in the machining process goes wrong, the absolute worst place for it to happen is on the machine. CNC machines are – at minimum – several tens of thousands of dollars. They’re investments. If one is to crash due to a cutting tool colliding with it, it is disastrous if not outright ruinous for a shop. Not only will the manufacturer lose time that could have been spent machining, but they will also have to pay to repair or replace the machine.

With a complete machine simulation package, problems are pinpointed while the part is still being programmed in the CAM software. The in-suite Simulation tool in Mastercam CAD/CAM software signals users not only if there is a collision detected, but also if there is a near-miss detected. Then, with just a few clicks, programmers are able to resolve the issues and keep working. When mistakes are found before the part goes to the machine, the only loss is time. And even then, the loss is minimal.

Learn more about Mastercam products by clicking below.

Leave A Comment