This blog post will outline the benefits of upgrading a Mastercam 2D Mill or Router seat to Mastercam 3D Mill or Router. There are many shops that only have the capability of machining using 3-axis. In recent years, as machines get older and are replaced or as shops expand, some are looking to add some form of multi-axis machine. We are going to look at moving directly from 3-axis machinery to 5-axis machinery. Since most jobs require multiple-sided work to reach completion.

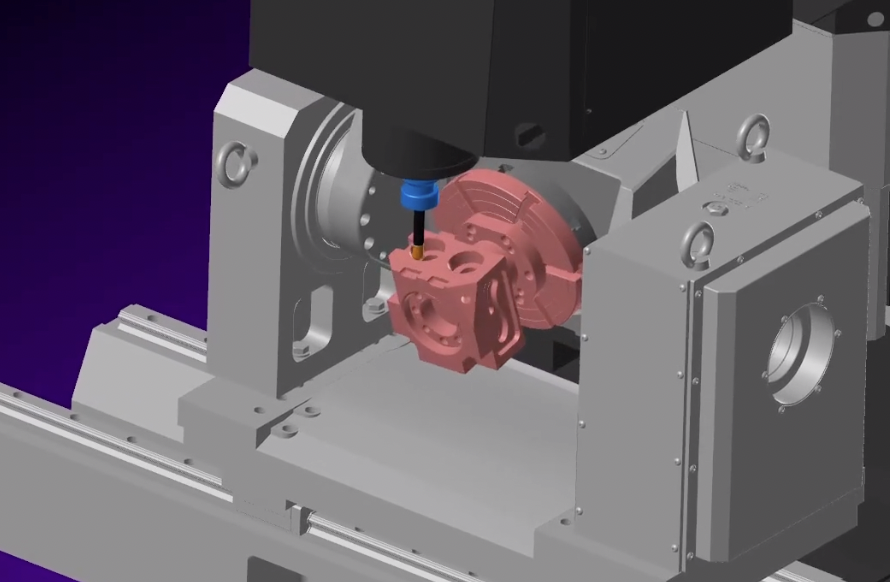

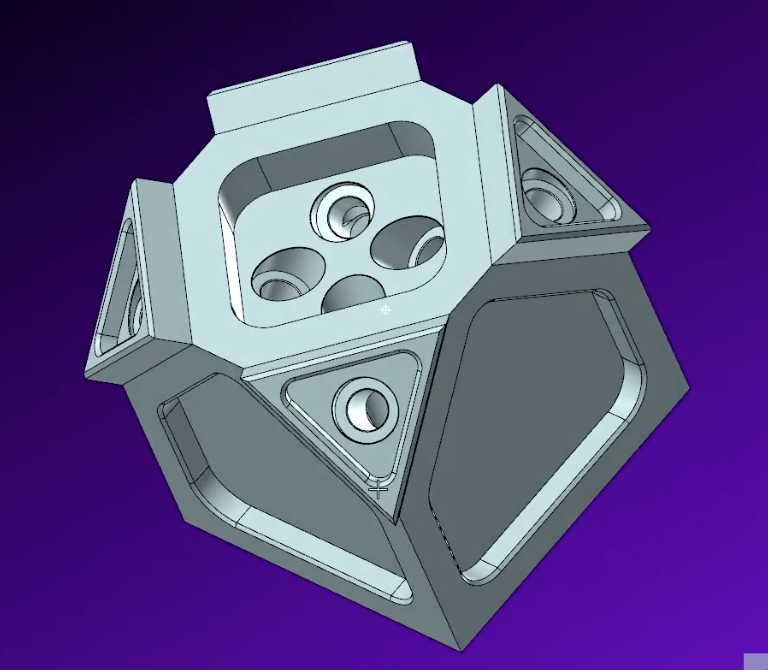

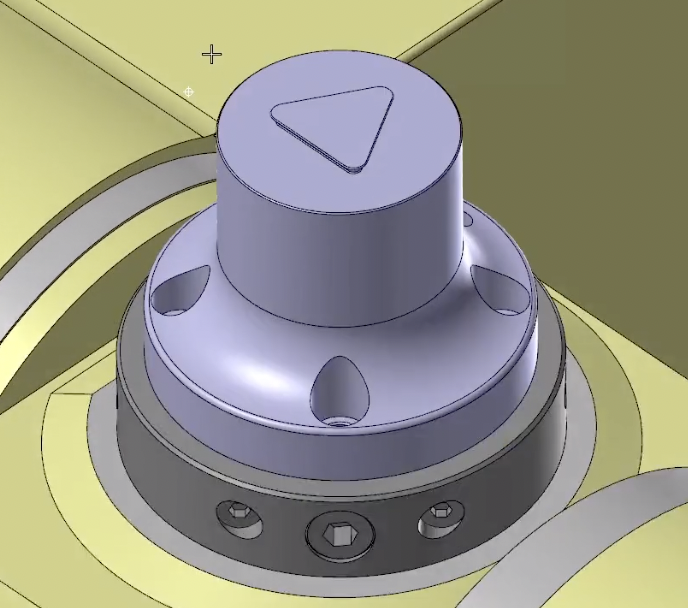

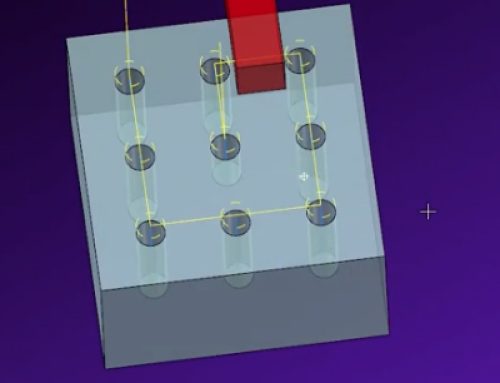

When using 3-axis equipment, parts will require multiple setups and possibly multiple fixtures to achieve the desired outcome. The sample part below would require programming on every face.

Since most of the faces are on compound angles, we need to use multiple unique fixtures. Some of these setups will require various repositions.

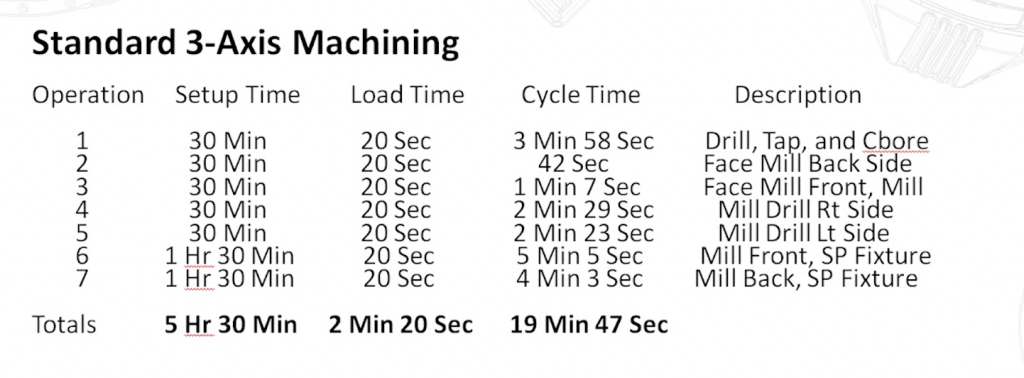

This sample part would take approximately 6 hours to complete with standard 3-axis machining.

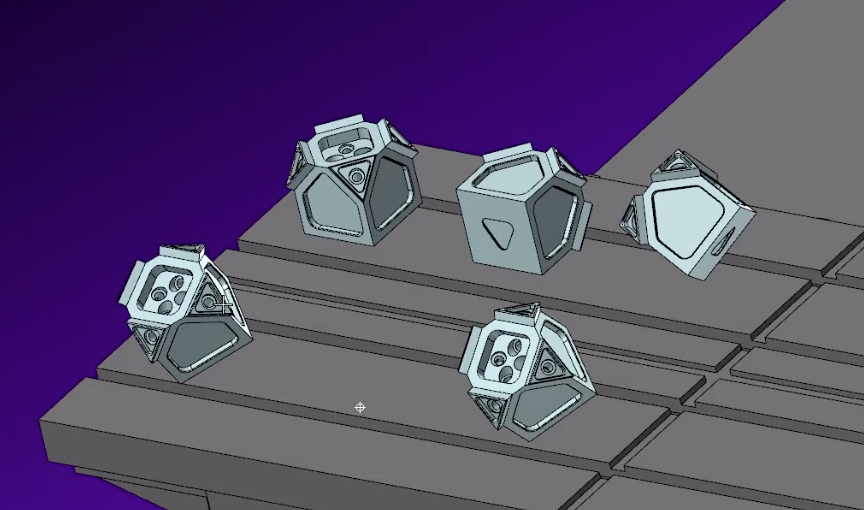

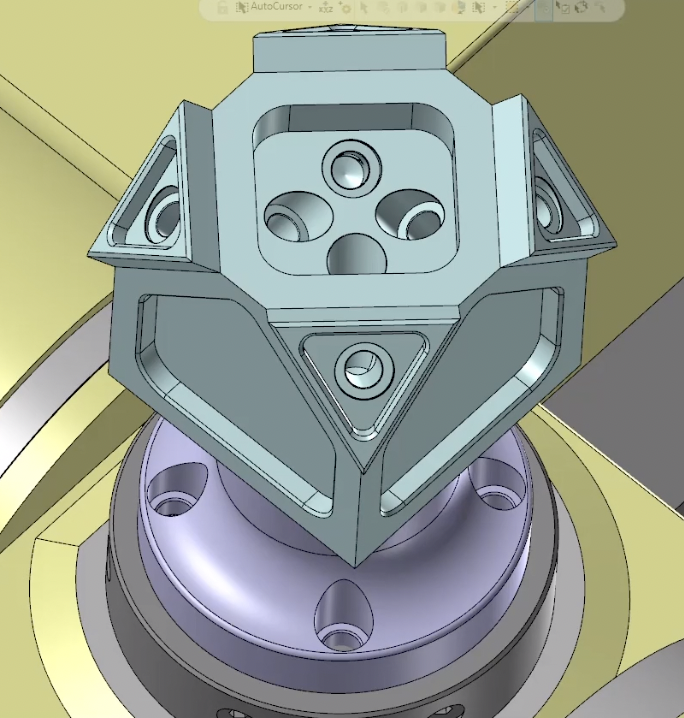

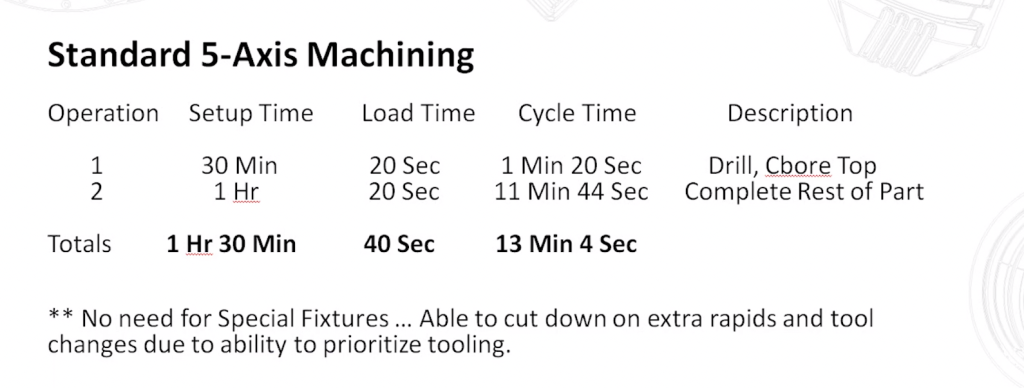

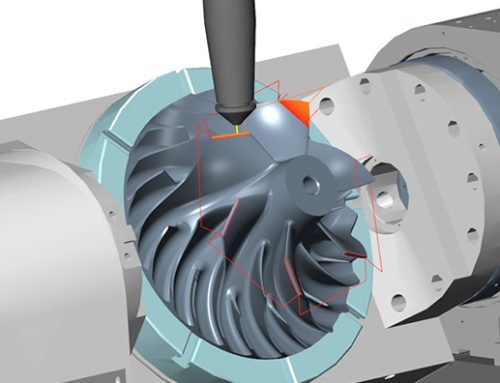

Let’s see how using Mastercam 3D and 5-axis machining can help. Using our example part and a dovetail fixture, we can mount the raw material from the center and be able to machine 5 of the 6 sides while also reaching all the angled features in a single setup.

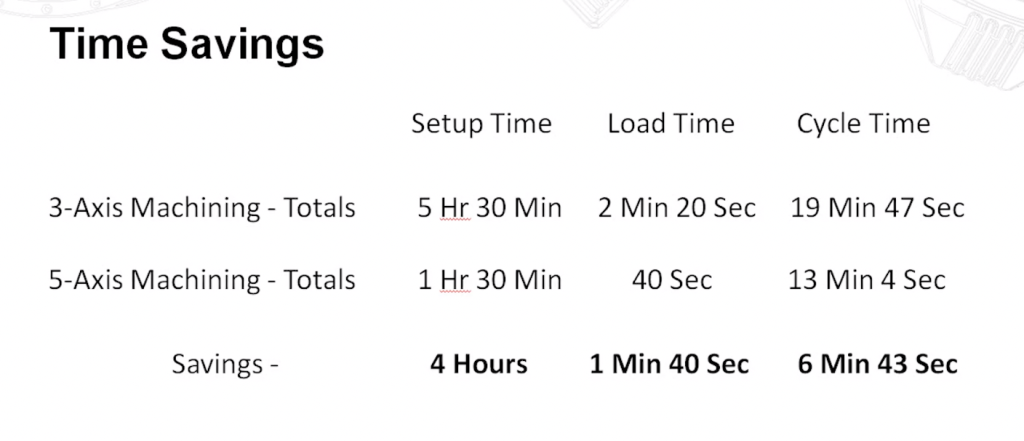

Using this process eliminates many of the part handling and repositioning steps you previously would have needed to implement. This new process has fewer steps. Previously, we had 5 setups, requiring 17 repositioning events. By using a multi-axis machine, we are down to 2 setups for the part, and one additional setup to machine the dovetail into the stock. This reduces the overall time to approximately 1 hour, 45 minutes.

A lot of the time savings comes not only from the reduced handling time but also from allowing you to reduce the number of tool changes. By eliminating the need to manually move the part from position to position, you can program using a tool prioritized process.

A lot of the time savings comes not only from the reduced handling time but also from allowing you to reduce the number of tool changes. By eliminating the need to manually move the part from position to position, you can program using a tool prioritized process.

As you can see, moving to a multi-axis machining process allows for a significant reduction in time per part. Another benefit is having much less clutter in the Mastercam files themselves, providing a further reduction in programming time. Please be sure to sign up for our 2 Minute Tuesday video series to receive tips and tricks like this one in video form every week. More info at the button below.

Leave A Comment