Design X Go: Reverse Engineering for Mastercam Has Arrived

Join Cimquest or this educational webinar to explore how Design X Go can serve as both a 2D and 3D CAD system as well as a reverse engineering tool to create machinable CAD models from scan data (mesh or point cloud) and is the bridge from scan or point cloud data to fully machinable models in Mastercam.

Recap of our Design X Go Webinar – Reverse Engineering for Mastercam Applications

This week, we introduced the brand new Design X Go (DXGo) product in a 60 minute Webinar. So I decided to make this month’s Metrology Minute focused on this awesome new reverse engineering product and how it can add value to any Mastercam user.

I wanted to take a moment here to thank Steve Weaber, from our awesome Mastercam support team, who assisted me by providing the Mastercam toolpath files used for the Webinar.

We presented three scenarios where DXGo can greatly enhance the productivity of a Mastercam user.

- 3D Modeling without the presence of a mesh or point cloud –

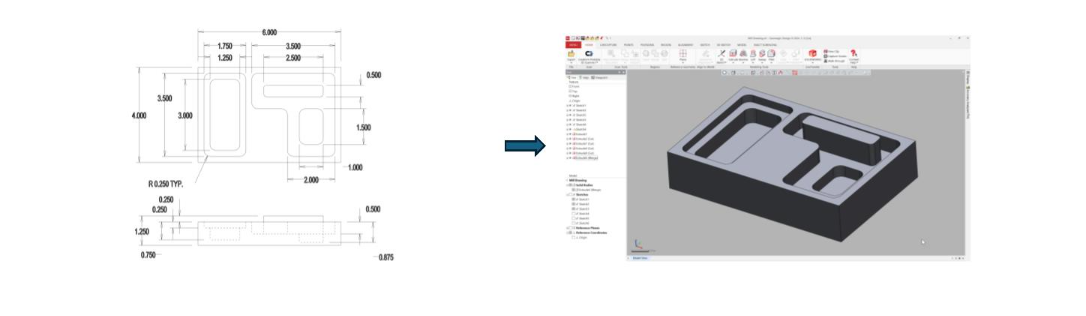

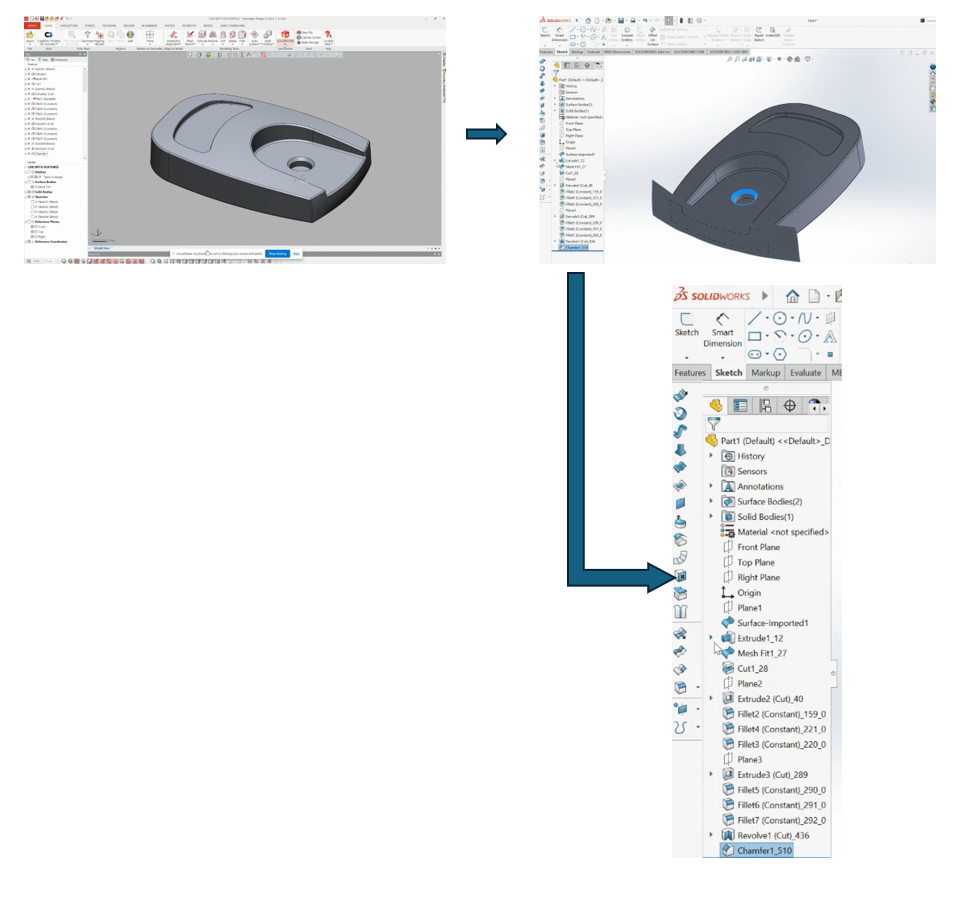

DXGo can function very much like the Part Modeler of any of the modern-day CAD products. We demonstrated the creation of a 3D model from one of the 2D drawings used during our Mastercam basic training class and passed the model, as a CAD-based Step file, into Mastercam for Dynamic Toolpath creation.

2D Drawing to 3D Model (CAD-Based Step File)

-NEXT –

CAD-Based Step File to Mastercam Machining Assembly – Dynamic Toolpath Creation

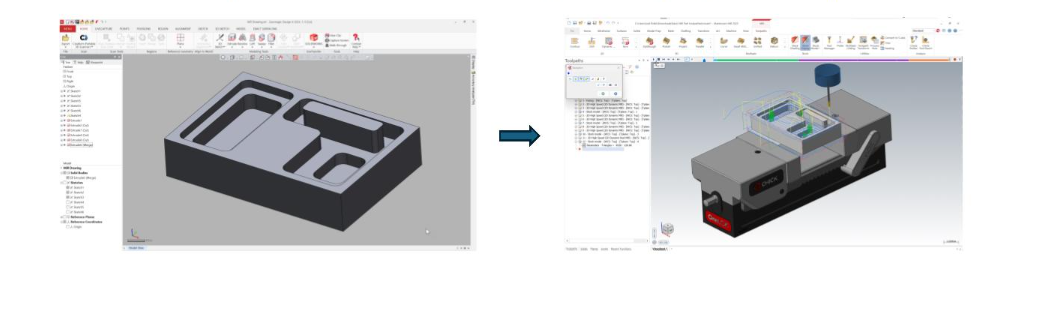

Development of Native CAD Data Using a DXGo Model! –

We also demonstrated the ‘Live Transfer’ process for transferring the DXGo model directly into a fully native Solidworks’ model, complete with planes, sketches, constraints, dimensions, features, etc. The resultant model appears as if it was created, from scratch, in native Solidworks. Take note of the complete Solidworks’ History Tree produced automatically from the Live Transfer!

Also keep in mind that the Live Transfer process works for several other popular CAD formats, not just Solidworks.

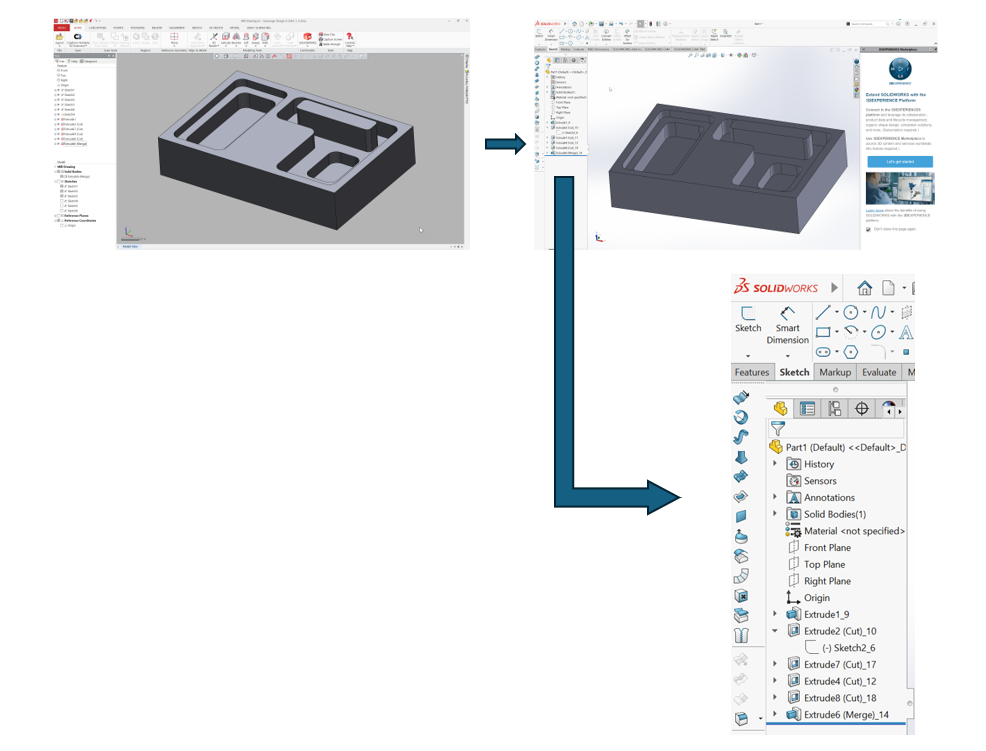

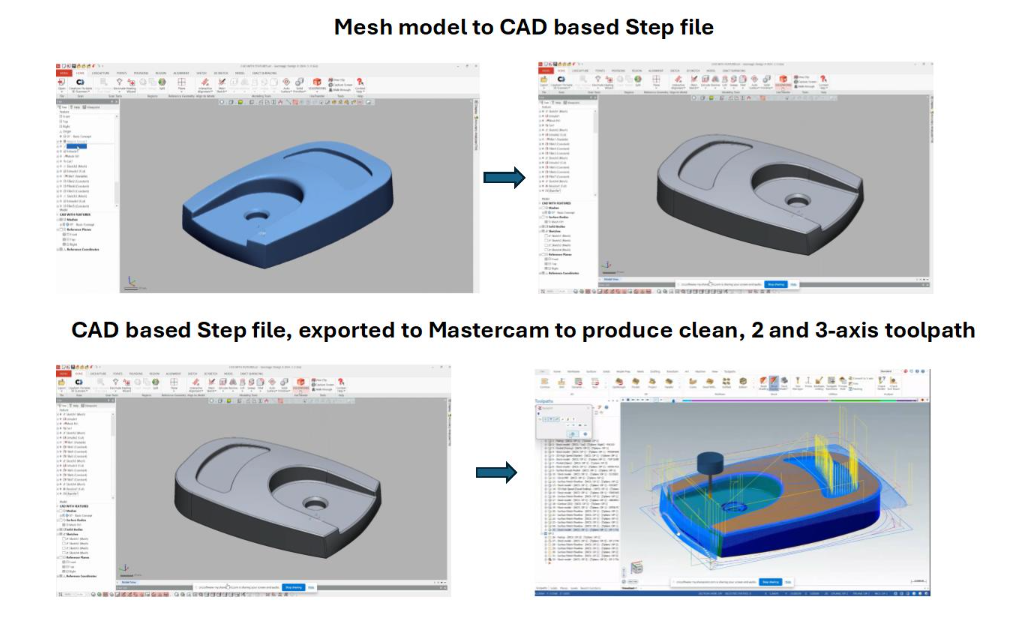

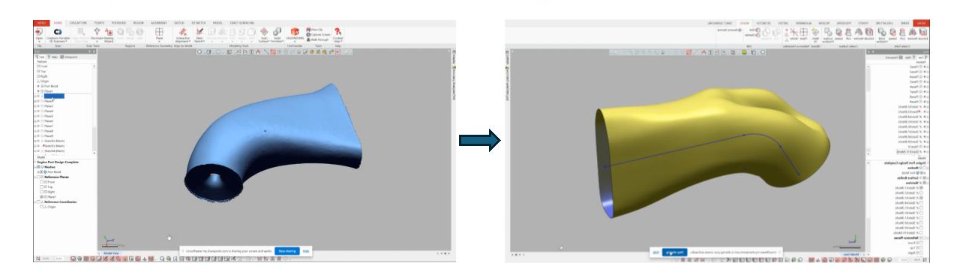

Basic 3D Model Creation from a Mesh –

We also showed how DXGo can take the scan of a basic part and use it as a template to model a CAD based Step file fully suited for CNC toolpath creation as well as a native CAD model. We Live Transfer to Solidworks again for our example.

CAD based Step file, exported to Mastercam to produce clean, 2 and 3-axis toolpath

We demonstrated DXGo’s ability to ‘Live Transfer’ CAD models produced from mesh data to native CAD as well, still utilizing Solidworks for our examples.

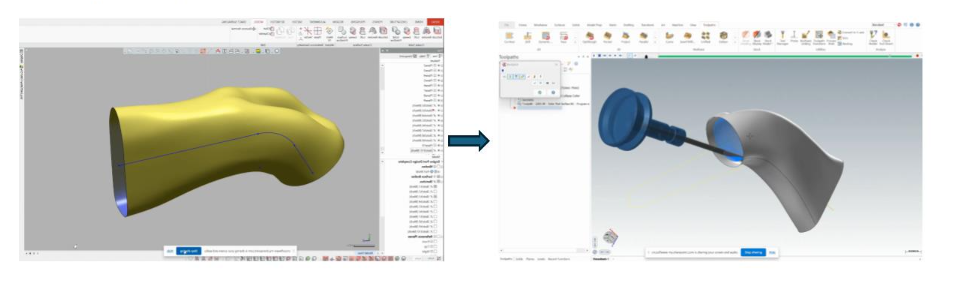

Creation of a complex Engine Port and Mastercam’s Port Expert

Finally, DXGo is no lightweight when it comes to complex surface modeling

Consider this…

We have a complex engine port shape with no CAD model and no direct way to scan the shape required for reverse engineering. Below is a cross-section of a similar engine port.

The port starts out as an oval, bends almost 90 degrees to a round shape, making it virtually impossible to scan and capture the complete contour. The port shape also presents machining challenges, even once a model does exist.

A button tool with a long shank can only reach in so far before a second setup is required to machine from the opposite end. You will see that the power of Mastercam and Port Expert easily handles this multi-axis complex task!

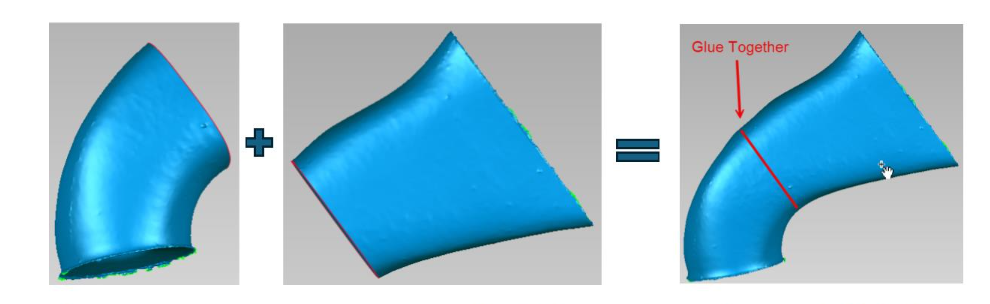

We start with a trip to the local hardware store to purchase an inexpensive molding material to attempt to create a mold of the port shape, as two chunks. We block off the port cavity at an approximate centerline and pour the material into both ends, allowing it to solidify. We then remove the two chunks to glue them together to form the complete engine port shape.

Next, we scan the shape, import the scan into DXGo and develop the complex Lofted surface, suitable for Mastercam’s Port Expert toolpath creation.

The final step was the transfer of the CAD based Step surface into Mastercam for 5-axis, Port Expert Toolpath creation.

Please click on the link below to watch a replay of the complete Webinar, and contact Cimquest for additional questions or to receive information regarding Design X Go!