Performing a Datum Alignment using Control X

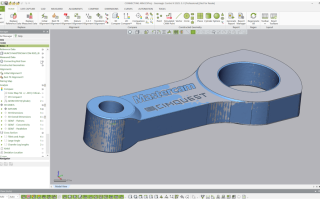

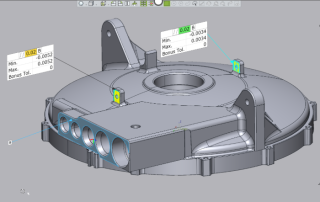

Performing a Datum Alignment using Control X Before the scan of a manufactured part can be inspected using Control X, it must first be aligned to its nominal CAD model. The nominal CAD model represents the ‘perfect’ shape. Once aligned, all of the Control X inspection functions, including Color maps, Whisker plots, 2D and 3D dimensions, Geometry Deviation, 2D Twist Analysis and more can all take place. Consider the water pump cover shown below, prior [...]