Breaking the Mold – Xact Metal for Tooling

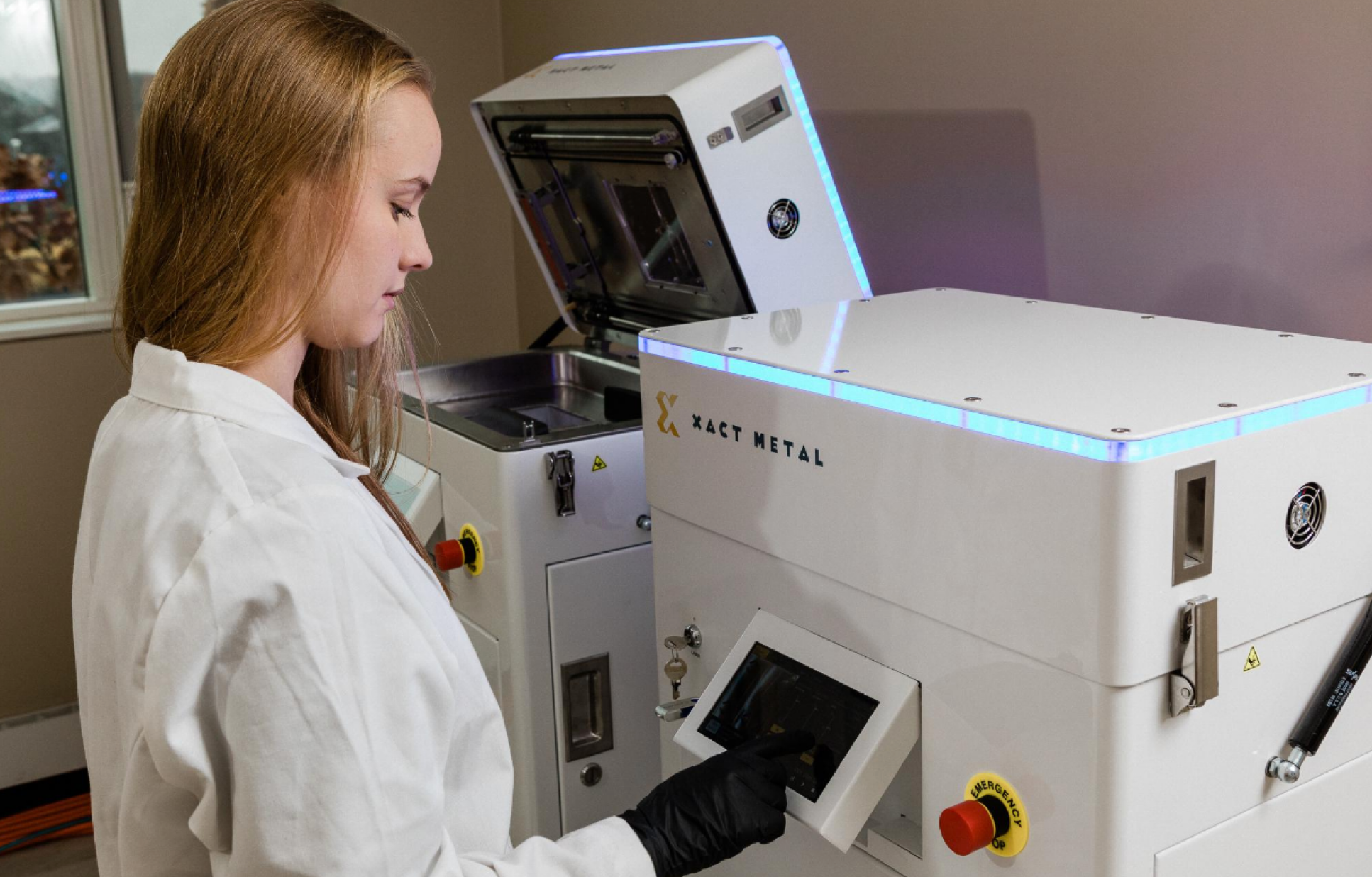

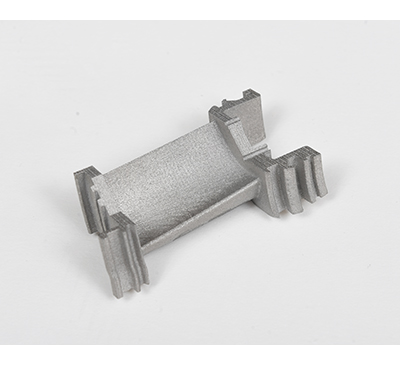

View the replay of the webinar featuring Cimquest and partner, Xact Metal, where we delve into the advantages of Xact Metal’s 3D printers and how they provide an innovative tooling workflow. Participants will gain insights into tooling concepts, diverse applications, Xact Metal’s proficiency in surface finish, tolerance, and materials, as well as discussions on return on investment (ROI).

Your Webinar Hosts:

Joe Kubicek:

Joseph Kubicek has invested over 40 years in manufacturing excellence and process automation technology. He is a published author and has been a guest lecturer to multiple universities and graduate schools of business. Joe is also a board advisor to several organizations.

Scott Kraemer:

With an impressive 33-year career spanning roles as a Directing Manager, Tooling Engineer, Application Engineer, and Mold Designer, Scott Kraemer has excelled in the development of complex injection multi-shot molds, tooling, and products across industries, including medical, automotive, and consumer goods. Over the past 13 years, Scott has been a trailblazer in the incorporation of additive manufacturing (3D printing) for both plastic and metal into mainstream production parts and tooling. A passion for educating others about opportunities within the manufacturing industry led Scott to create the PTI Technical Academy program, which gained approval from the State of Michigan. This program provides high school students with hands-on training and showcases various career paths within the plastic injection molding industry. As of 2023, Scott has begun work with Xact Metal, a metal 3D printer manufacturer that shares his goal of integrating additive manufacturing technology into mainstream production and tooling.