Request an HP Sample Part

Get a Free HP Sample Part

By leveraging 3D printing, you can produce anything — from flexible parts to the most complex parts. Expand into new applications and markets with a growing portfolio of HP 3D materials that enable you to produce a variety of low-cost, quality parts— and address sustainability objectives with industry-leading reusability.

Below are examples of complex parts that additive manufacturing can produce. Would you like to see and touch them?

Request a FREE sample.

Custom Insole – PA11:

This orthotic was printed with HP’s 3D HR PA 11, a thermoplastic material (derived from vegetable castor oil, a renewable raw material to reduce environmental impact). It delivers optimal mechanical properties, providing excellent chemical resistance and enhanced elongation-at-break. PA11 is ideal for producing strong parts that require good impact resistance and ductility such as; prostheses, insoles, sporting goods, snap-fits, living hinges, etc.

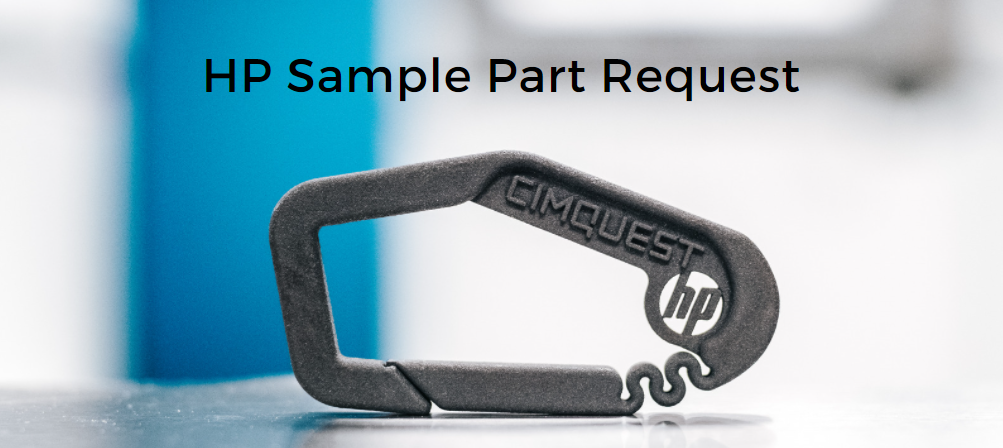

Carabiner & Gear – PA12:

Both the carabiner and the gear were printed with HP’s 3D HR PA 12, a robust thermoplastic that produces high-density parts with balanced property profiles and strong structures. PA 12 is engineered to produce final parts and functional prototypes with fine detail and dimensional accuracy. In addition, it provides excellent chemical resistance to oils, greases, aliphatic hydrocarbons, and alkalies. This material is ideal for producing strong, functional, detailed complex parts including; assemblies, housings, enclosures, and watertight applications as well as parts that require biocompatibility certifications (such as USP Class I-VI and US FDA guidance for Intact Skin Surface Devices).

Drone Propeller – PA12 with 40% glass beads:

The propeller was printed in HP’s 3D HR PA 12 Glass Beads, a thermoplastic material filled with 40% glass beads. PA12GB is a good fit for functional parts that require high stiffness as well as dimensional stability and repeatability. The combination of detail and dimensional accuracy are ideal for parts such as; enclosures, housings, fixtures, and tooling.

Race Car – PA12 Color Boost:

This full-color race car was printed in HP’s 3D HR CB PA 12, a robust engineering-grade thermoplastic that produces high-density parts with balanced property profiles and strong structures. PA 12 CB provides excellent chemical resistance to oils, greases, aliphatic hydrocarbons, and alkalies. In addition, it is designed for the production of full-color and white functional parts such as; jigs, fixtures, labeling, presentation models, and functional prototypes.

Flexible Clip – Polypropylene from BASF:

The flexible clip was produced using HP’s 3D High Reusability PP enabled by BASF, a genuine polypropylene material. It has excellent chemical resistance and low moisture absorption as well as outstanding welding capabilities with other PP parts (produced with traditional methods like injection molding). This is a versatile material used in a wide range of automotive, industrial, consumer goods and medical applications. It is ideal for piping, fluid systems, containers and parts that require biocompatibility certifications (meets ISO 10993 and US FDA guidance for Intact Skin Surface Devices).

Flexible Part – TPA from Evonik:

The flexible part was printed with HP’s 3D High Reusability TPA enabled by Evonik, a flexible polyamide (PA); one of the most used additive manufacturing materials in a thermoplastic elastomer that is easy-to-process. Parts produced in TPA are flexible (with enhanced rebound resilience and elongation-at-break) lightweight and provide a high level of detail and color uniformity. They also have optimal mechanical resistance at low temperatures. As such , this material is ideal for applications like winter sports equipment, car interiors, robotics & grippers, and fluid systems. This part was finished using Additive Manufacturing Technologies’ PostPro Vapor Smoothing process.

Finger Brace – TPU from BASF:

This splint was printed with BASF’s Ultrasint® TPU01, a multi-purpose thermoplastic polyurethane (TPU) powder. This material is ideal for producing functional parts with good flexibility, shock absorption, and requires fine structures with a high level of detail. The TPU01 powder is easy-to-print with good UV and hydrolysis resistance. This part was finished using Additive Manufacturing Technologies’ PostPro Vapor Smoothing process.

Bellows -TPU from Lubrizol:

This bellows was printed in ESTANE® 3D TPU M95A which is a thermoplastic polyurethane (TPU) powder developed by Lubrizol. Parts are produced for a wide variety of applications that require high elasticity, good abrasion resistance, and high-impact absorption. This part was colored using DyeMansion’s DM60 dyeing process.