Office-friendly metal 3D printing in just 2 steps — Print. Sinter.

Easy, Two-step Processing

Making complex, high-performance metal parts has never been easier. Featuring a breakthrough two-step process, next-generation Separable Supports, and a software-controlled workflow, the Studio System 2 makes it simpler than ever to produce custom metal parts.

- Print to sinter

- Software controlled workflow

- Smart separable supports

- User-friendly hardware

High-quality Parts

Easily produce difficult-to-machine parts featuring complex geometry like undercuts and internal channels. Fabricate, the software at the heart of the Studio System, automates complicated metallurgical processes to produce high-quality parts with densities and feature accuracy similar to casting.

- Reliable processing

- Excellent part properties

- Customizable print settings

Designed for the Office

The Studio System 2 was designed from the ground-up to fit into your team’s workflow. With no solvents, no loose metal powders or lasers and very little operator intervention required, the system makes it easy to start printing metal parts – no third party equipment or special facilities required.

- No special facilities requirement

- Hands-off process

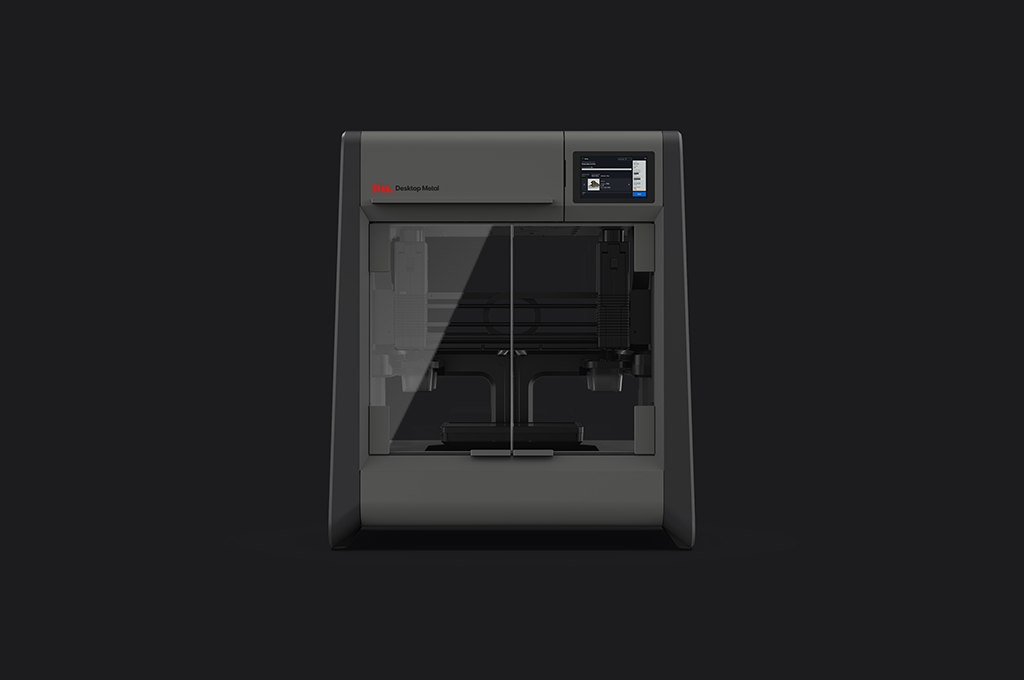

Printer

Unlike laser-based systems that selectively melt metal powder, the Studio System extrudes bound metal rods—similar to how an FDM printer works. This eliminates many of the safety requirements often associated with metal 3D printing while enabling new features like the use of fully closed-cell infill for lightweight strength.

Furnace

Designed to be the easiest to use sintering furnace made, the Studio System 2 furnace first heats parts to remove all binders from parts, then ramps up the temperature to near-melting to deliver industrial-strength sintering in an office-friendly package. Built-in temperature profiles tuned to every build and material ensure uniform heating and cooling without the residual stresses introduced in laser-based systems.