Form Fuse 1+

Bring industrial-quality prototyping and production in-house with affordable, professional SLS 3D printing

Designed for maximum output and minimum waste, Fuse 1+ 30W is the compact SLS 3D printer that packs an industrial punch. Unlock unprecedented print speeds and material enablement to deliver truly rapid production in-house.

Superior Print Speeds

Deliver high-precision parts within 24 hours thanks to a powerful, 30W laser that prints at scan speeds of up to 12.5 meters per second.

Industrial Grade Materials

Unlock exclusive, new materials and achieve higher performance on existing ones with active powder handling and an inert gas print option.

Zero Waste, High ROI

By optimizing packing density and powder recyclability, we’ve reached a major milestone: zero waste printing, enabling lower cost per part.

Strong, Functional SLS Materials

3D print production-ready, end-use parts with our family of SLS Powders, developed specifically for the Fuse Series printers. Our materials, hardware, and software are developed and validated together to deliver peak performance while optimizing cost per part.

Benefit from enhanced mechanical properties and higher powder recyclability when utilizing Fuse 1+ 30W’s inert gas atmosphere print option.

Available now: Nylon 11, Nylon 12, Nylon 12 GF, and Nylon 11 CF Powders. Stay tuned for regular releases of exciting, new materials currently in development.

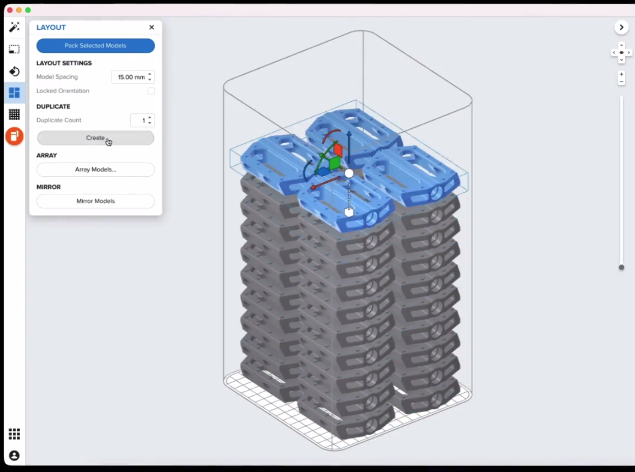

Maximize prints with minimal setup.

Use our free print preparation software, PreForm, to import STL or OBJ files, orient models, estimate print times, and monitor prints.

PreForm’s part packing algorithms can automatically arrange many models in a build to maximize the packing density, reduce print time, and limit waste.

SLS made manageable

During setup and printing, an intuitive Touch UI walks you through every step.

The touchscreen displays a live stream of the print bed so you can watch each new layer take shape. This camera view is also available from your computer in PreForm so you can monitor your print without leaving your desk.

Track printers, teams, and supplies via the cloud-based Dashboard.

Reliable, consistent printing

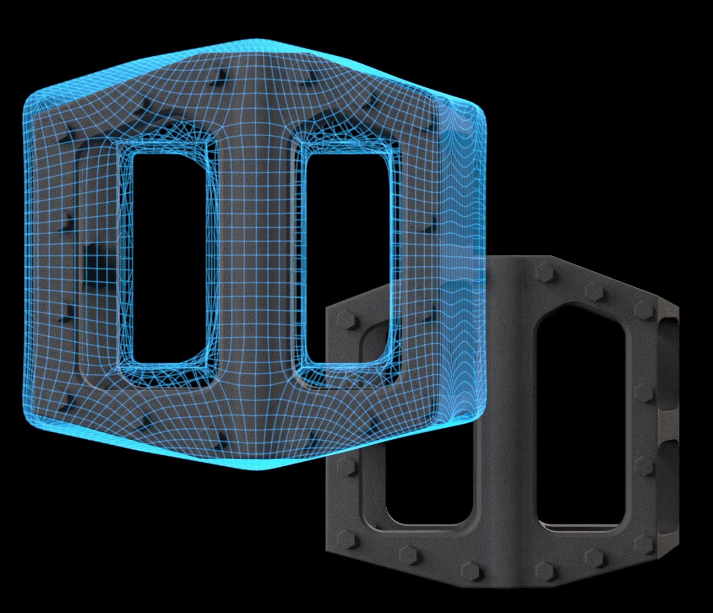

SLS 3D printing fuses powder layer by layer. The unused material supports the parts during printing so you can create complex, interconnecting designs with no need for support structures.

Patent-pending Surface Armor technology creates a semi-sintered shell around the surface of each part, enhancing mechanical properties and surface quality without the hassle of a large, industrial footprint. These qualities are heightened even further when using the inert gas print option available with Fuse 1+ 30W.

All-in-one powder recycling and recovery.

Our all-in-one powder recovery station, Fuse Sift, combines part extraction, powder recovery, storage, and mixing in a single device.

Produce fully-functional parts with competitively high powder recyclability to enable less waste and lower cost per part.

Fuse Sift will dispense and mix used and new powder automatically so you can reduce waste and control your powder supply.

Fuse Blast

Achieve professional, consistent parts that are clean to the touch faster and easier than ever before with Fuse Blast, an easy-to-use, fully automated cleaning and polishing solution for post-processing SLS 3D printed parts.

Why Choose the Fuse Blast

Fuse Blast delivers 100% hands-off cleaning and polishing for SLS parts.

Finished Parts In 15 Minutes

Cleaning routines automatically post-process an entire build chamber in as little as 15 minutes, while the passive filtering reduces media saturation and extends media life to save on overhead costs.

Consistent Results

Pre-programmed routines take out the guesswork for consistent results, while manual mode allows you to adapt to any part requirements.

Professional Parts

Deliver clean-to-the-touch parts thanks to the in-line ionizer that prevents dust and media from re-settling on your parts, or go the extra mile with the optional polishing function for a smooth, semi-gloss, and dye-ready surface finish.

Streamlined Post-Processing

Fuse Blast seamlessly integrates into the Fuse ecosystem for an automated post-processing workflow that reduces labor time by 80% and delivers finished parts in as little as 15 minutes.

Designed for 24/7 throughput.

Achieve faster-than-ever printing speeds to deliver prototypes and small series of end-use parts in under 24 hours.

Enable continuous throughput by adding a second, removable build chamber to any Fuse Series workflow.

Industry-leading rapid cooldown times allow you to start a new print within 1-2 hours of your previous print job.