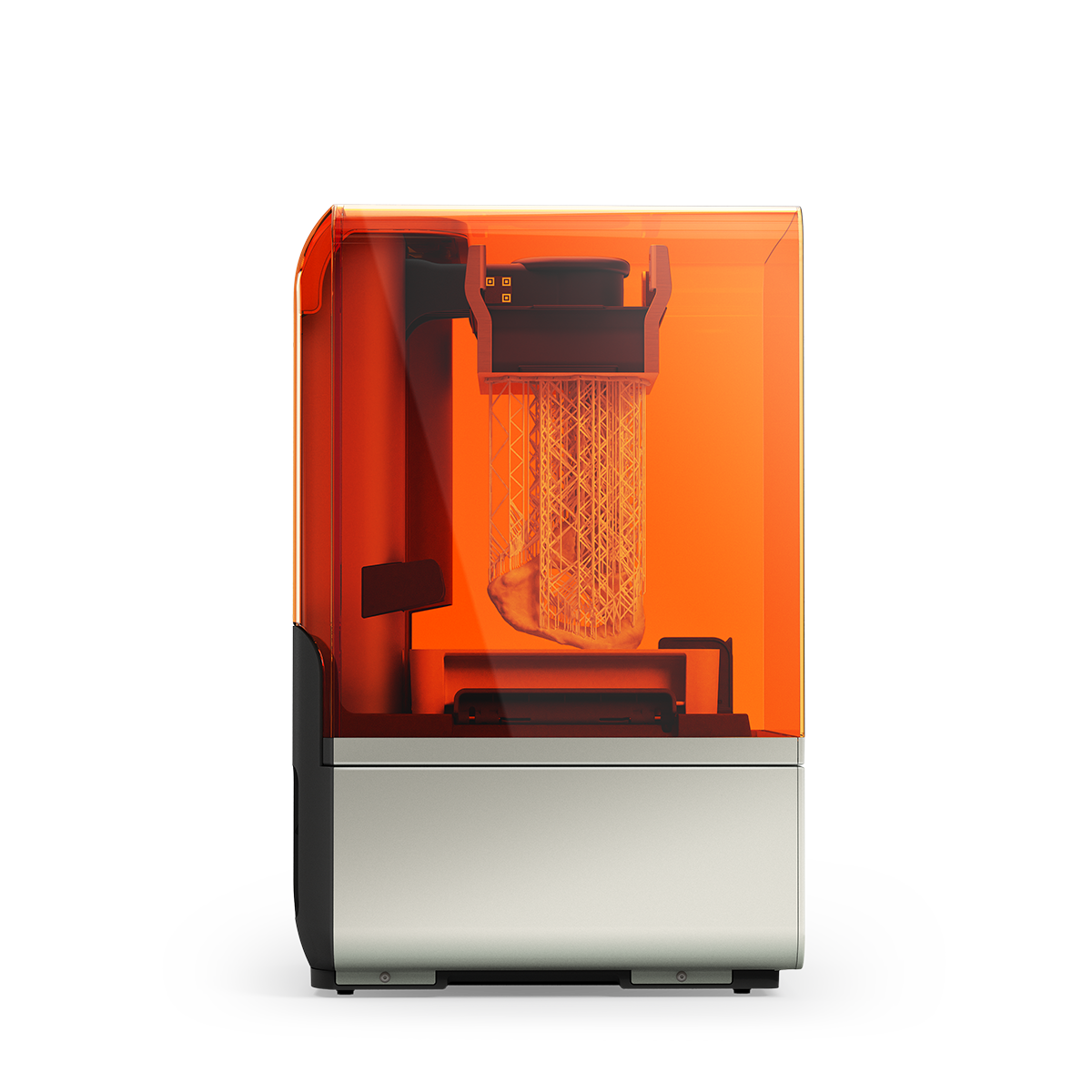

Large prints, incredible resolution.

At the heart of the machine is a powerful optical engine guided by custom-built galvanometers, delivering big prints with spectacular detail. A high precision laser draws parts at 25-100 micron resolution, delivering accuracy on par with industrial 3D printers.

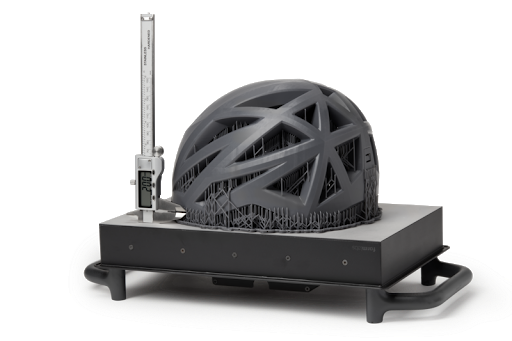

High-Resolution 3D Printing

The Form 2 enables you to print precise models with stunning surface finish – significantly smoother and more detailed than other plastic 3D printing technologies. Save time and money post processing, and spend more time on creating.

Engineered for precision.

Designed for reliability.

A new peel mechanism, wiper, and heated resin tank create a consistent environment and reliable print process. 3D print solid parts as well as small intricate details with high dimensional accuracy.

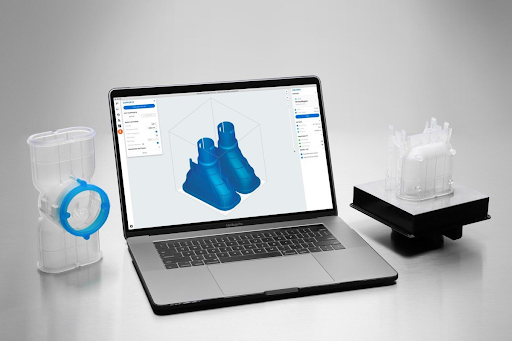

Formlabs Material Resin Library

Standard Resins – Custom-formulated to deliver the highest-quality output, our Standard Resins capture astonishing detail without sacrificing strength.

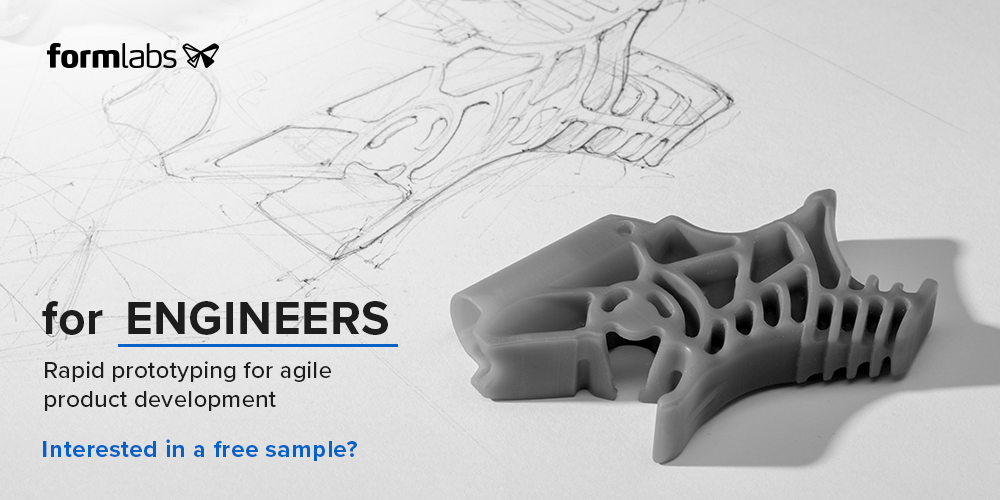

Engineering Resins – Our Engineering Resins are designed to simulate a wide range of injection-molded plastics, and include: Tough, Durable, Flexible, and High Temp.

Jewelry Resins – Castable Resin burns out cleanly without ash or residue and captures fine detail and smooth surfaces.