Introducing the NEW Ultimaker Factor 4

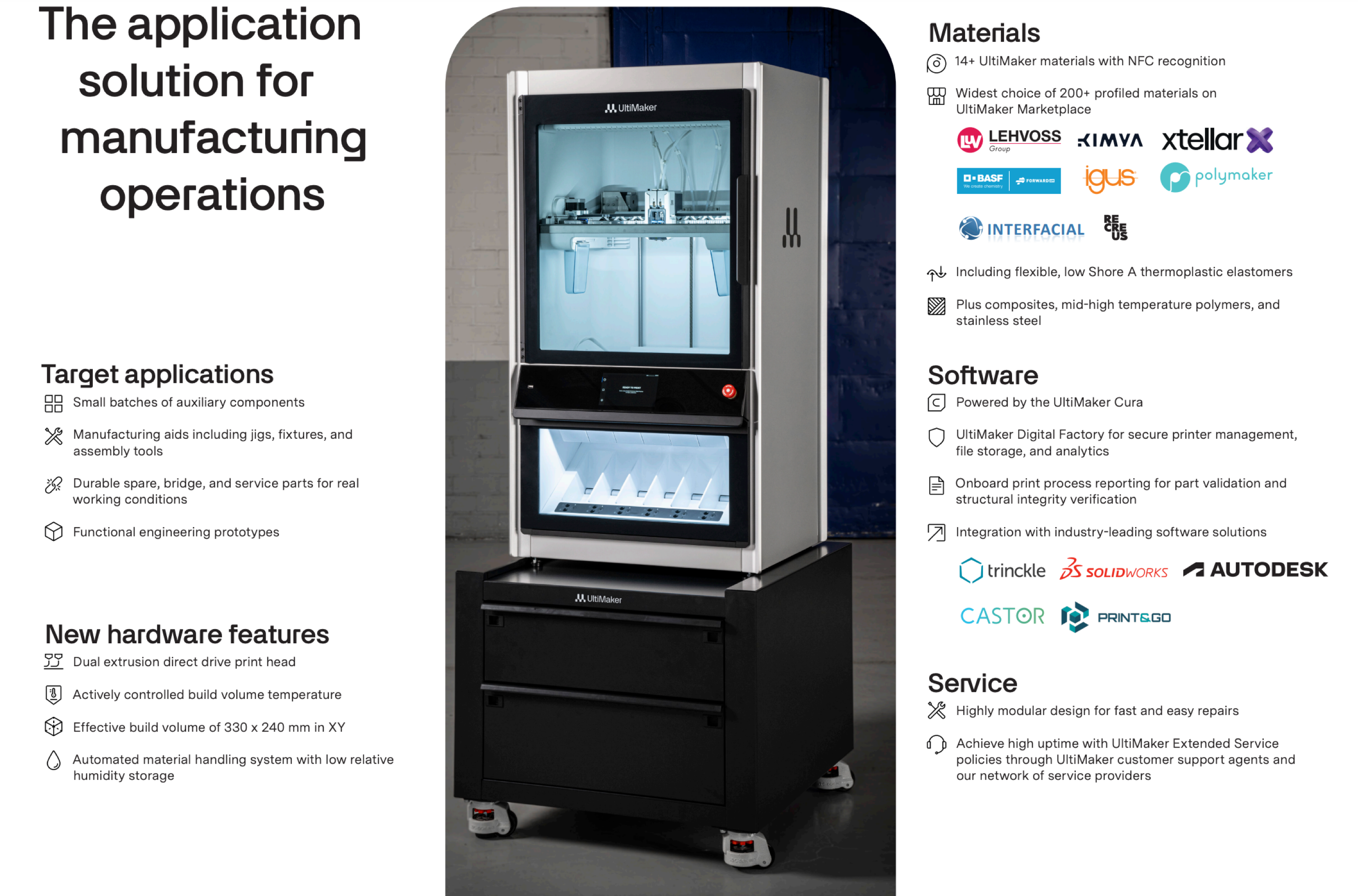

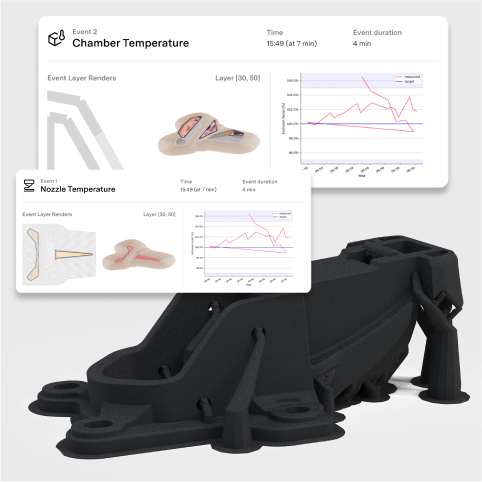

An end-to-end application solution, UltiMaker Factor 4 is tailored for the development, production, and full-confidence deployment of process-critical tools and machine components. Factor 4 keeps operations running, simplifying processes in factories, and reducing human-triggered variabilities. It streamlines factory floor operations with its large effective build volume, direct dual material extrusion, and onboard print process reporting to achieve unrivaled predictability and minimal variance.

Accurate applications from design to industrial

• Achieve more with FDM 3D printing

• Built for the factory floor

• A future-proof investment

Packed with technology for maximum predictability

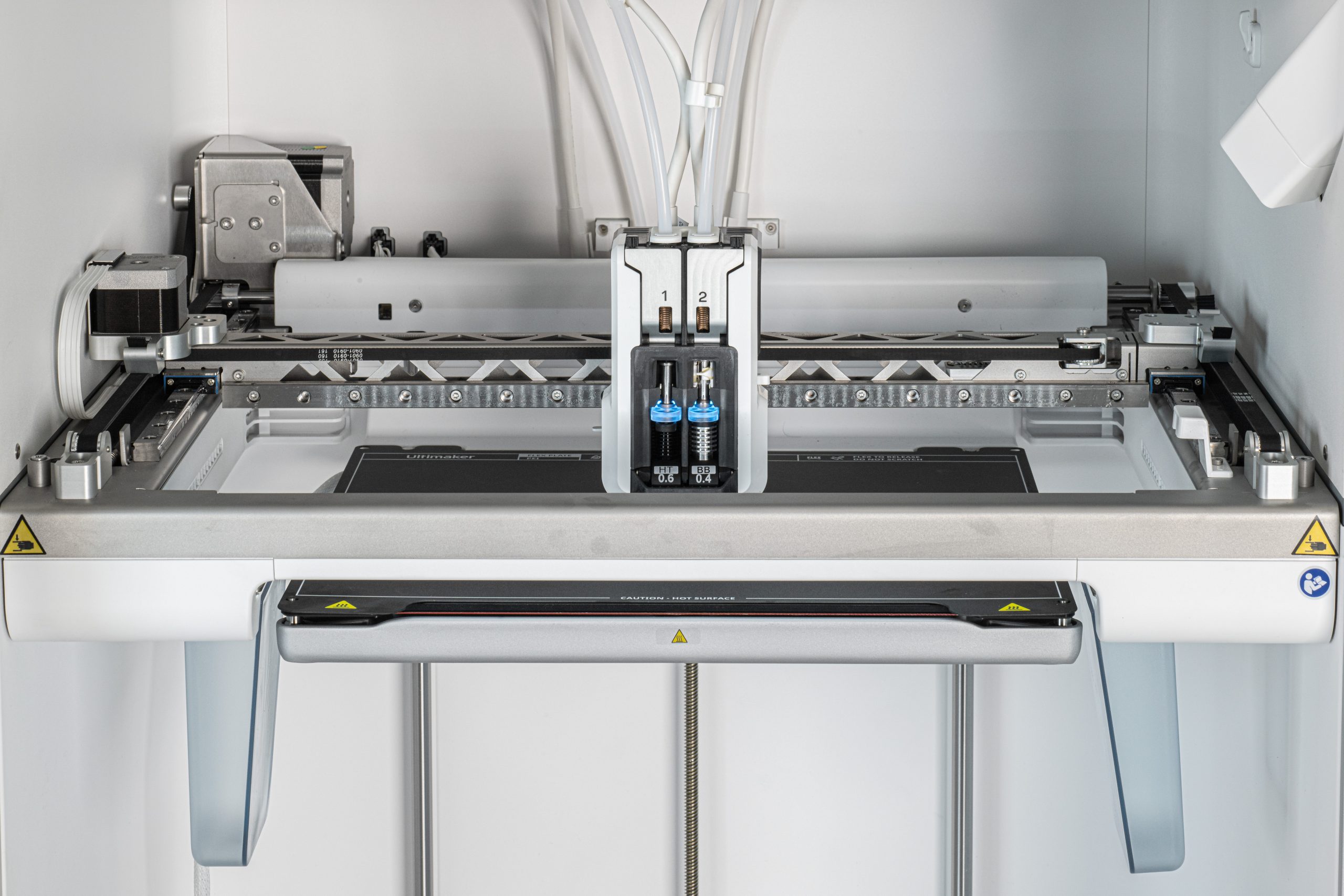

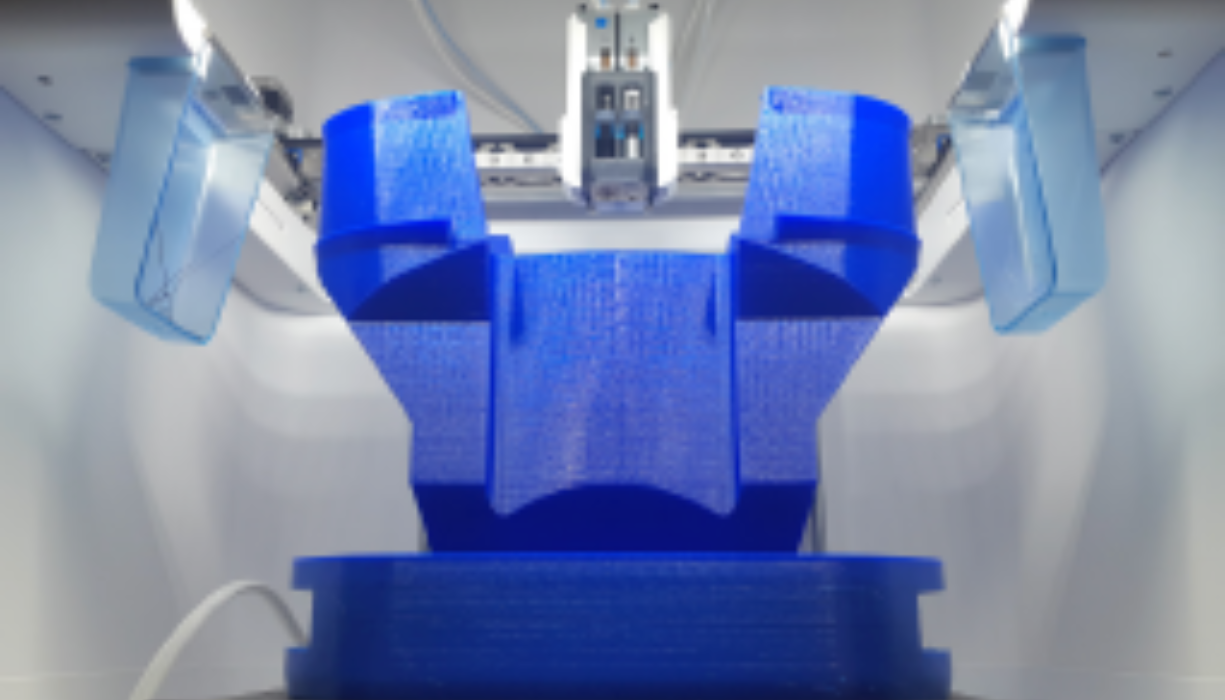

Fully redesigned extrusion train

The combination of the all-new H-bridge gantry and direct drive extrusion print head allows high-speed movement and positional accuracy of ±0.2 mm or ±0.2% of the feature’s nominal length with UltiMaker Verified Materials. This results in best-in-class dual material printing speeds so that you can quickly create the flexible

or strong parts you need

Hassle-free material handling

A new, integrated, automatic material handling system reliably manages your spools so you don’t have to. The internal chamber is kept at less than 10% RH in office conditions, so you can keep up to 6 kilograms of filament in perfect condition for back-to-back print jobs.

Actively temperature controlled build volume

UltiMaker Factor 4 raises the temperature up to 340°C using the HT print core. This means that you can now 3D print higher temperature-resistant and durable materials withmore confidence.

The temperature within the fully enclosed build volume is also controlled up to 70°C, with a heated bed up to 120°C, ensuring optimal material-specific processing conditions and consistent part quality wherever the 3D printer is located.

Features summary

Printing properties: Technology Fused deposition modeling (FDM)

Extrusion system: Dual-extrusion, direct drive print head with unique auto-nozzle lifting system and swappable print cores

Build volume: Single material printing: 330x240x300mm (13×9.4×11.8in)

Dual material printing: 330x240x300mm (13×9.4×11.8in)

Filament diameter: 2.85mm

Print profiles availability: 14+ UltiMaker materials

200+ UltiMaker Marketplace materials

Dimensional accuracy: ±0.2mm ±0.2% feature nominal length.

Innovation powered by material diversity

UltiMaker PPS-CF is a new high- temperature composite for Factor 4that can replace complex steel parts. Its heat deflection temperature is greater than 230 °C. It’s chemical resistant and flame retardant (UL94 V0), making it a versatile choice for demanding applications.

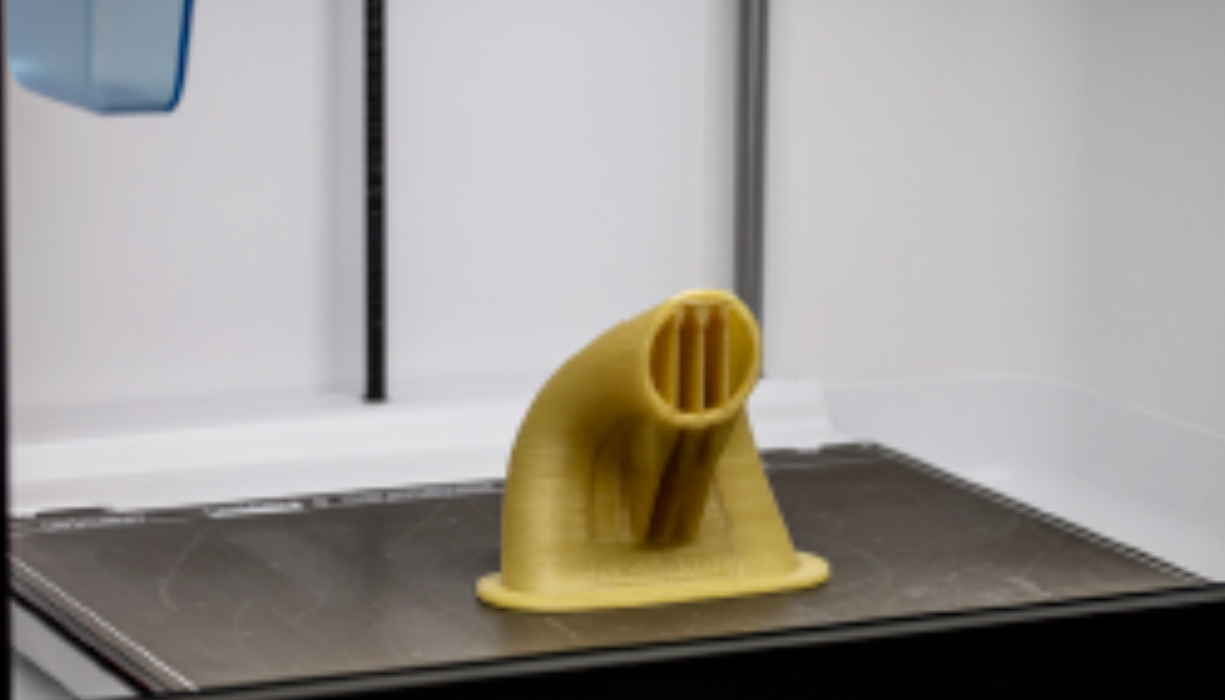

Large flexible parts in TPU 95A to TPU 70A

Flexible materials down to Shore 70A means you can reliably protect parts from damage and create gaskets, seals, and shock absorbers.

Access to 200+ Marketplace materials

A wide range of high-performance and certified material properties opens up a huge range of new 3D printing applications on Factor 4.