Maximize the Throughput of Your 3D Printer Fleet

Skyrocket your ability to produce high-quality, affordable parts with 24/7 back-to-back production. Automatically operate your fleet to eliminate idle printer time with easy-to-implement solutions that require no extra training.

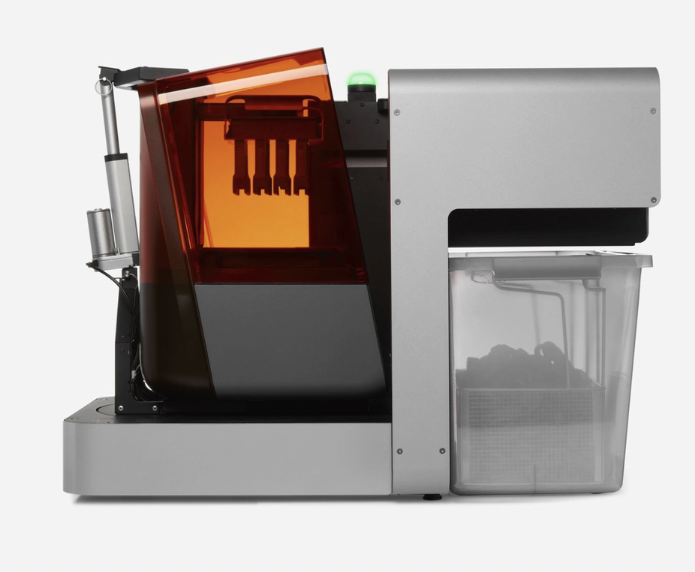

Form Auto

Automation Hardware for Your Form 3/3+ 3D Printers

Form Auto is an automated hardware extension for Form 3/3+ 3D printers that automatically removes finished parts from the Build Platform 2 and starts the next print without the need for operator interaction, enabling 24/7 printing without downtime.

Form Auto can finish and accept new prints autonomously to work through a multi-print queue. Click ‘Print’ from anywhere, and have many parts waiting for you.

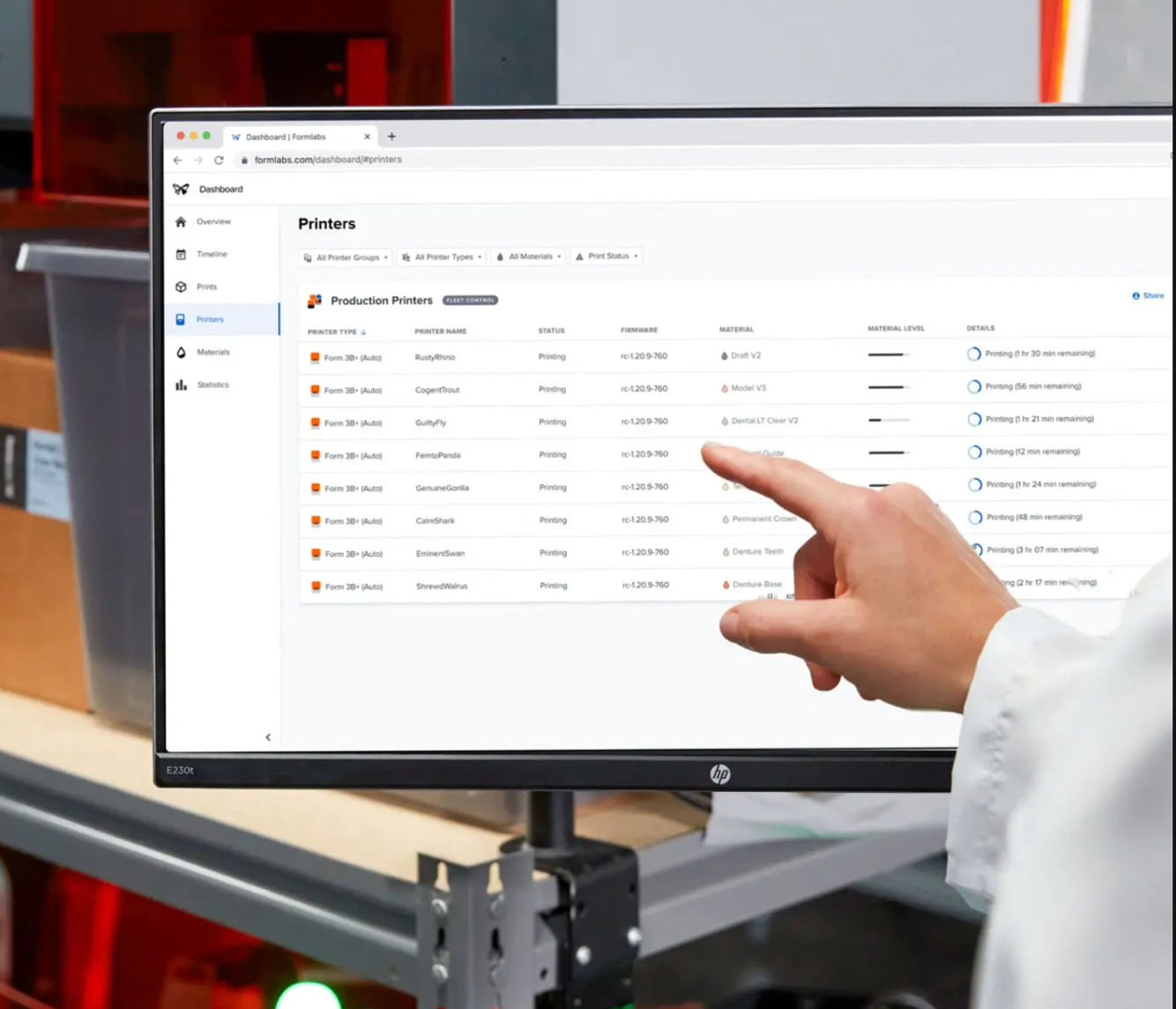

Fleet Control

Advanced Printer Management Software

Fleet Control activates new, advanced features within our PreForm and Dashboard software that leverage automation and workflow optimization for advanced fleet management.

Transform how you manage a fleet of Formlabs SLA 3D printers and a group of users with automatic print-to-printer assignment, streamlined queueing, and optimized management.

High Volume Resin System

Seamless Resin Supply

The High Volume Resin System pumps resin directly into the resin tank from an external 5L Resin Bag, increasing your printer’s resin supply by five times the standard cartridge volume and reducing packaging waste by 96%.

The High Volume Resin System is made up of a 5L Resin Bag and a Resin Pump.

Save Money and Time

Minimize cost per part with labor savings of up to 80%*. The Formlabs Automation Ecosystem lets you significantly reduce the amount of labor needed to create each part. By printing, removing parts, and starting the next print autonomously, production doesn’t have to stop when you leave work. With Form Auto, batch post-process a bin full of parts at once in minutes.

How to make 1000 3D printed rotating arms (Grey Resin) in three days**:

| SET UP | WITH AUTOMATION ECOSYSTEM | WITHOUT AUTOMATION ECOSYSTEM |

|---|---|---|

| Printers Needed | 10 | 28 |

| Number of cartridge changes | 2 | 12 |

| Operators required | 1 | 1 |

| Cost per part | $2.81 | $3.93 |

* Calculation based on dental arches printed in Draft Resin at 200µm.

**Calculation includes equipment and labor costs, and amortization.

Start Scaling Your Production Now

Work more efficiently and redefine production capacity in your 3D printing workflow with Formlabs Automation Ecosystem including Form Auto, Fleet Control, and the High Volume Resin System.

Scale your part production without increasing printer management complexity. Hit send from anywhere and the Formlabs Automation Ecosystem will take care of the rest.

Realize the Benefits of High-Throughput Automated 3D Printing

Scale capacity with demand and produce parts more quickly and affordably than ever with Form Auto, Fleet Control, and the High Volume Resin System by Formlabs.

Resin Pumping System

The Formlabs Resin Pumping System is an accessory for Form 3 Series stereolithography (SLA) 3D printers that seamlessly delivers 5 L of resin through a pumping system directly to the printer’s resin tank. Reduce waste by 86%, improve efficiency with less frequent cartridge changes, and unlock bulk pricing on Formlabs SLA resins.

What’s Included:

- Resin Pump

- Transfer Tube

Compatibility:

Printer compatibility: Form 3, Form 3+, Form 3B, Form 3B+, Form 3L, Form 3BL

Availability & Shipping

- Available to ship immediately for Form 3, Form 3B

- Form 3L & Form 3BL support coming in the next printer firmware release

*Resin Pumping System is compatible with most Formlabs Resins. Check the support site for more information.

**Some resins may have a higher minimum order quantity