Form Fuse 1

Bring industrial-quality prototyping and production in-house with affordable, professional SLS 3D printing

The Fuse 1 delivers industrial power in a small footprint with effective powder containment and easy setup. From print setup to powder recovery, our easy-to-use hardware and software are designed to maximize your efficiency at every step of the process.

With final parts that combine strength, flexibility, and detail, Fuse 1 prints are ready for rigorous functional testing, or to ship ready-to-use products to customers.

Intuitive

The Fuse 1 is designed for minimal upkeep. A full-color touchscreen interface guides you through every step of printing and maintenance.

Affordable

With reduced equipment cost, affordable material, and efficient powder recycling, the Fuse 1 is the smart choice for industrial quality SLS 3D printing.

Efficient

From print setup to powder recovery, our easy-to-use hardware and software are designed to maximize your efficiency at every step of the process.

A Material That Does It All

This isn’t your average 3D printed plastic. Nylon will bend and return to its original form, rather than fracturing suddenly.

11%

ELONGATION AT BREAK

Nylon 12 available at launch, Nylon 11 and other materials in development.

Sturdy Under Stress

Nylon is perfect for structural, load-bearing, or mechanical parts.

50 MPa

TENSILE STRENGTH

Nylon 12 available at launch, Nylon 11 and other materials in development.

Withstand the Elements

Nylon is suitable for high-temperature applications and parts that need to tolerate heat.

171 °C / 340 °F @ 0.45 MPa

HEAT DEFLECTION TEMPERATURE

Nylon 12 available at launch, Nylon 11 and other materials in development.

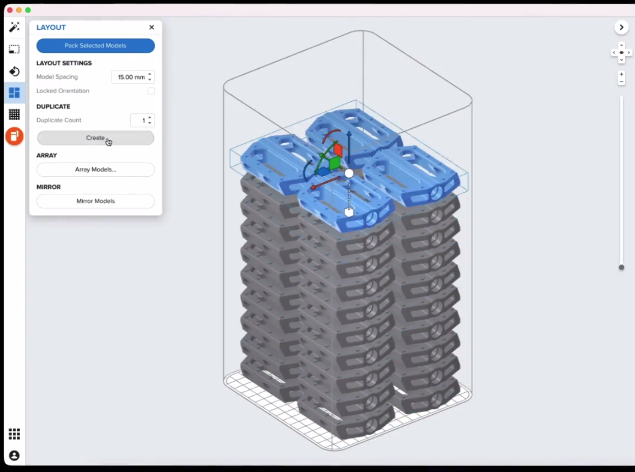

Fast, simple print setup

Use Formlabs PreForm print preparation software (free to download and try) to import STL or OBJ part files, orient and arrange models, estimate print times, monitor your printers, and upload job files.

PreForm’s part packing algorithms can automatically arrange many models in a build.

SLS made manageable

During setup and printing, an intuitive Touch UI walks you through every step.

The touchscreen displays a live stream of the print bed so you can watch each new layer take shape. This camera view is also available from your computer in PreForm so you can monitor your print without leaving your desk.

Track printers, teams, and supplies via the cloud-based Dashboard.

Reliable, consistent printing

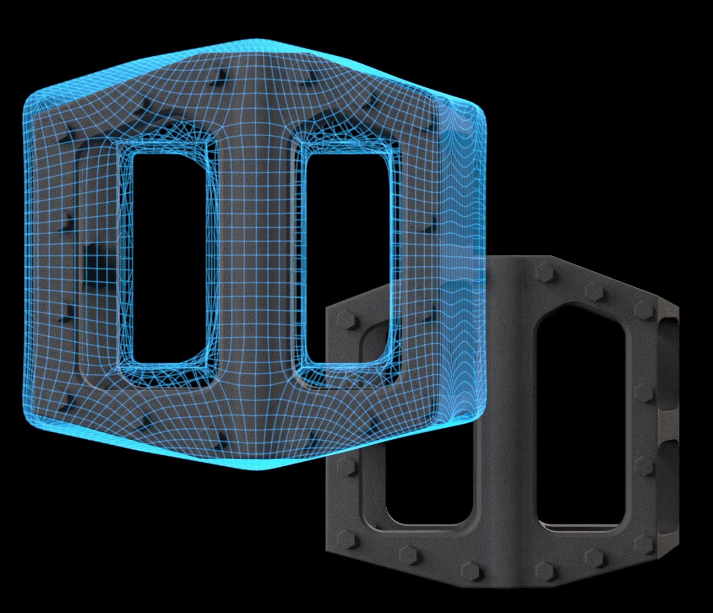

SLS 3D printing fuses nylon powder layer by layer. The unused powder supports the parts during printing so you can create complex, interconnecting designs with no need for support structures.

With patent-pending Surface Armor technology, a semi-sintered shell that prints around the surface of the part, the Fuse 1 provides competitive mechanical properties and surface finish without the prohibitive cost or hassle of competitor systems.

FUSE SIFT

The Fuse Sift is a safe, efficient powder recovery system for the Fuse 1 3D printer. This easy-to-use, all-in-one station combines part extraction, powder recovery, storage, and mixing in a single free-standing device, for the most functionality in a single device available on the SLS market.

- Compact, enclosed system: A negative air pressure system keeps powder inside while enabling open access and easy cleanup.

- Low waste: A 30% material refresh rate means you can print with up to 70% recycled powder, indefinitely. Fuse Sift’s sieve filters out particles to be remixed with new powder and reused in future prints.

- Automatic powder mixing: Fuse Sift will dispense and mix used and new powder automatically so you can reduce waste and control your powder supply.

- Nonstop printing: Reduce downtime by transferring modular build chambers and powder cartridges between the Fuse 1 and Fuse Sift for a nonstop, cyclical workflow.

- A complete toolkit: The Fuse Sift includes a set of finishing tools to help you clean excess powder from parts with ease.

ALWAYS PRINTING

A removable build chamber enables continuous printing and reduces downtime.

With the Fuse 1, you can print with up to 70% recycled powder.