Unlock Innovation with Formlabs Open SLA Materials

Formlabs’ Open Material Mode allows users to print with any 405 nm photopolymer resin on their SLA printers. This feature is available for a one-time lifetime fee per printer, providing perpetual access to third-party materials without ongoing licensing fees12.

Ideal For:

- Research and Development: Perfect for expert users and R&D teams looking to innovate and experiment with new materials.

- Specialized Applications: Ideal for industries requiring specific material properties not available in standard Formlabs resins.

Key Benefits:

- Versatility: Print with a wide range of 405 nm photopolymer resins, expanding your material options beyond Formlabs’ proprietary resins1.

Cost-Effective: Avoid recurring licensing fees and enjoy continuous exploration of new materials3.

Customization: Tailor print settings to match the specific properties of your chosen resin, ensuring optimal print quality and performance1.

How to Activate Open Material Mode: - Cost Effictive:Avoid recurring licensing fees and enjoy continuous exploration of new materials3.

Customization: Tailor print settings to match the specific properties of your chosen resin, ensuring optimal print quality and performance. - Customization:Tailor print settings to match the specific properties of your chosen resin, ensuring optimal print quality and performance.

Formlabs Advanced 3D Printing Materials

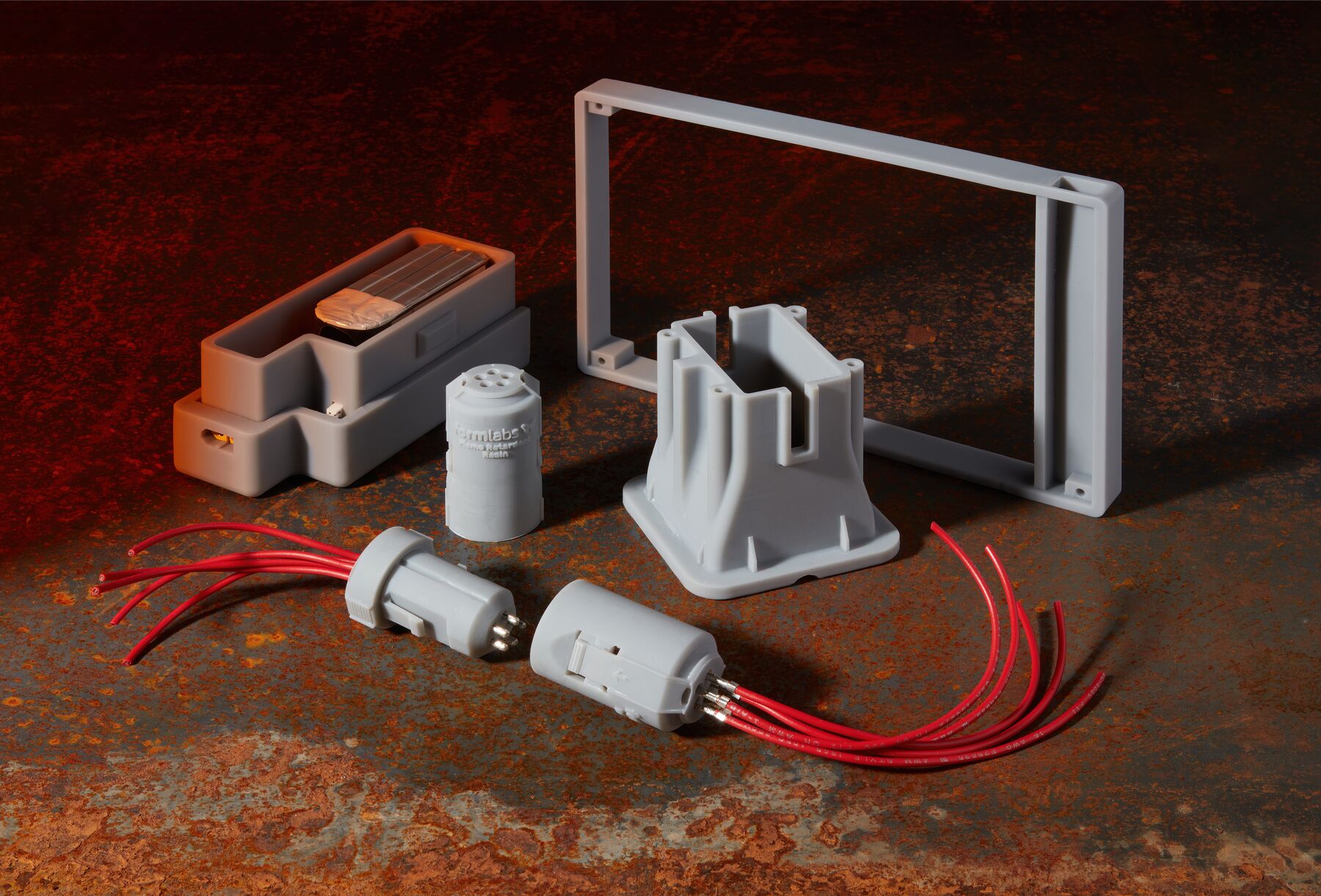

Engineering Resins

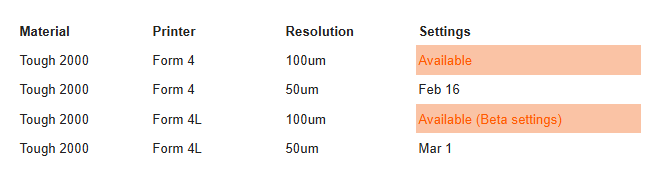

Tough 2000 Resin V2

The new Tough 2000 Resin V2 is the strongest and stiffest Tough material, and our most popular engineering resin today, with strength and stiffness comparable to ABS. The new Tough 2000 Resin V2 builds upon this success by combining toughness with high temperature and creep resistance for end-use parts that look and perform like production components.

Tough 2000 has beta settings available for Form 4 and Form 4L.

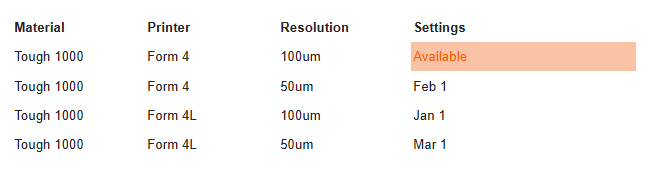

Tough 1000 Resin

The new Tough 1000 Resin V1 is the most ductile and impact-resistant material in our Tough Family. It has comparable strength, stiffness, and toughness to high-density polyethylene. It’s designed with exceptional wear and fatigue resistance for long-term toughness and utility. It’s engineered for end use parts that need to bend, flex, or take impact without breaking.

Please Note: Tough 1000 will not be immediately available for Form 4L customers to print with.

Tough 1500 Resin V2

Tough 1500 Resin V2 is a resilient material with strength, stiffness, and toughness comparable to polypropylene (PP), offering exceptional resistance to fractures, impacts, and shattering.

Create parts that balance stiffness and ductility, whether for compliant mechanisms or rugged enclosures with self-tapping screws and snap fits. Tough 1500 Resin V2 enables a wide range of applications, from functional prototypes to end-use jigs and fixtures.

Tough 1500 Resin V2 is a new material formulation that leverages the Form 4 Series to deliver 10 times higher fracture toughness than the previous version.

Alumina 4N Resin 2 kg (780 mL)

Ceramic Wash Solution

The Ceramic Wash Solution is a specialized wash liquid for cleaning your ceramic 3D-printed parts. A wash in this solution is required for parts printed in Alumina 4N Resin.

Ceramic Wash Solution is non-hazardous and non-flammable.

Silicone 40A Resin 1 L

Introducing Silicone 40A Resin, the first accessible 100% silicone 3D printing resin. Eliminate molding and labor-intensive casting processes: Silicone 40A Resin uses Formlabs’ patent-pending Pure Silicone Technology™ to 3D print pure silicone parts in-house, in a matter of hours.

Flame Retardant Resin 1Kg (0.84L)

Drive innovation more quickly, safely, and efficiently with Formlabs’ new self-extinguishing and halogen-free SLA material with a UL 94 V-0 certification and favorable flame, smoke, and toxicity (FST) ratings.Use FR Resin to easily 3D print flame retardant, heat-resistant, stiff, and creep-resistant parts that will perform well long-term in indoor and industrial environments with high

temperatures or ignition sources.

*Compatible with Form 3 and Form 4

High Temp Resin for High Thermal Stability

High Temp is ideal for applications requiring the part to stand up to high temperatures with minimal loading. The material has almost no flex, however, so snap fits and living hinges are not suited for printing with High Temp Resin

- Hot air, gas, and fluid flow

- Heat resistant mounts, housings, and fixtures

- Molds and inserts

*Compatible with Form 3

Rigid 4K for Stiff, Strong, Engineering-Grade Prototypes

Designed for stiffness and precision. The material is reinforced with glass to offer a very high modulus and a polished finish.

- Thin walls and features

- Turbines and fan blades

- Jigs, fixtures, and tools

- Manifolds

- Electrical casings and automotive housings

*Compatible with Form 3 and Form 4

ESD Resin

ESD Resin is a specialty material for producing custom ESD-safe prototypes and production tooling to increase operational efficiency and improve the yield of electronics manufacturing lines. Parts printed in ESD Resin are static-dissipative, repel dust and powder, and have high modulus and impact strength similar to ABS.

*Compatible with Form 2, 3, 3+, 3B, 3B+, 3L, 3BL, 4, 4B

Tough 1500 Resin

Tough 1500 Resin is a resilient, skin-safe material that offers similar strength and stiffness to polypropylene (PP). Choose Tough 1500 Resin for stiff and pliable parts that bend and spring back quickly, prototypes that repeatedly bend and quickly return to shape, and jigs and fixtures requiring repeated deflection.

*Compatible with Form 2, 3, 3+, 3B, 3B+, 3L, 3BL, 4, 4B

PU Rigid 650

PU Rigid 650 is a pliable, tough, and impact-resistant material for demanding mechanical applications. Create real polyurethane parts that are resistant to light, heat, and chemicals using a unique workflow leveraging hybrid chemistry. PU Resins have a longer workflow requiring additional equipment and set-up costs.

*Compatible with Form 2, 3, 3+, 3B, 3B+, 3L, 3BL, 4, 4B

PU Rigid 1000

PU Rigid 1000 Resin is a stiff, sturdy, and strong material for demanding mechanical applications. Create real polyurethane parts that are resistant to light, heat, and chemicals using a unique workflow leveraging hybrid chemistry. PU Resins have a longer workflow requiring additional equipment and set-up costs.

*Compatible with Form 2, 3, 3+, 3B, 3B+, 3L, 3BL, 4, 4B

Medical Resins

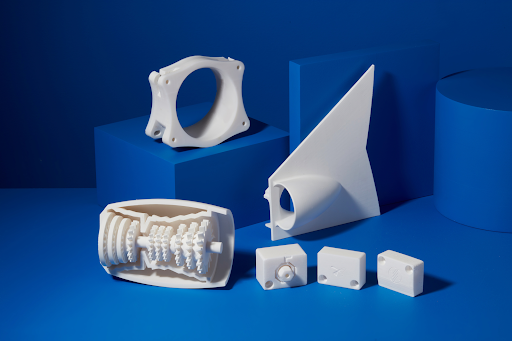

Rigid 10K – Rigid, Strong, Industrial-Grade Prototypes

Rigid 10K Resin offers high stiffness, strength, and resistance to heat and chemicals, making it a game-changing industrial material for the most demanding jobs. With a stiffness simulating that of glass and fiber-filled thermoplastics.

- Strong and stiff functional prototypes

- Temperature and chemical resistant prototypes

- High-temperature injection molding masters

- Stiff and strong aerodynamic test models

- Air and fluid flow components

*Compatible with Form 3 and Form 4

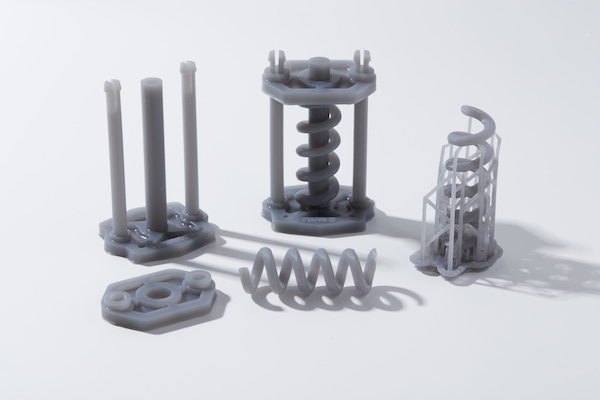

Flexible 80A for Hard Flexible Prototypes

Flexible 80A Resin can withstand bending, flexing, and compression, even through repeated cycles. It is the most stiff soft-touch material in Flexible and Elastic Resins, with an 80A Shore durometer, balancing softness with strength

- Soft-touch, tactile prototypes

- Seals and gaskets

- Consumer products and wearables

- Medical devices and anatomical models

- Props and modelmaking

*Compatible with Form 3 and Form 4

Elastic 50A for Soft Flexible Prototypes

An elastomeric material designed for applications requiring high elongation and high energy return. Use Elastic 50A Resin for parts that will bend, stretch, compress, and hold up to repeated cycles without tearing.

- Wearables and consumer goods prototyping

- Medical models and devices

- Compliant features for robotics

- Special effects props and models

*Compatible with Form 3 and Form 4

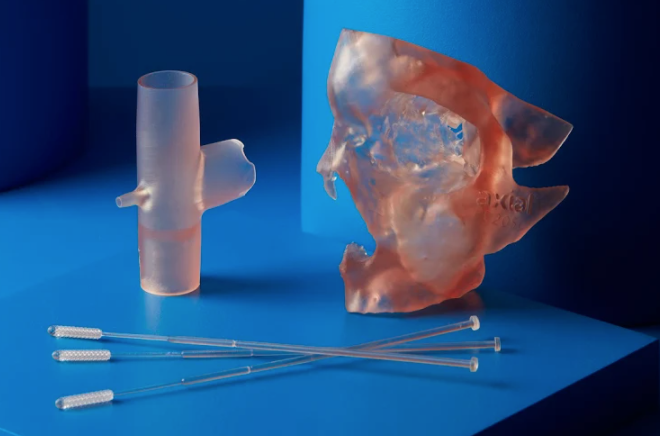

BioMed Flex 80A Resin

- Firm, flexible, medical-grade material

- Suitable for applications requiring:

- Durability

- Biocompatibility

- Transparency

- ISO 10993 and USP Class VI certified

- Manufactured in an FDA-registered, ISO 13485 facility

- Appropriate for use in applications for:

- Long-term skin contact (>30 days)

- Short-term mucosal membrane contact (<24 hours)

*Compatible with Form 3 and Form 4

BioMed Black Resin

BioMed Black Resin is a rigid, matte material for biocompatible applications requiring long-term skin (>30 days) or short-term mucosal membrane contact (<24 hours). Parts printed with BioMed Black Resin are compatible with common solvent disinfection and sterilization methods. BioMed Black Resin is manufactured in our ISO 13485 facility.

*Compatible with Form 2, 3B, 3B+, 3BL, 4B

BioMed White Resin

BioMed White Resin is a rigid material for biocompatible applications requiring long-term skin (>30 days) or short-term bone, tissue, dentin, and mucosal membrane contact (<24 hours). BioMed White Resin is manufactured in our ISO 13485 facility.

*Compatible with Form 2, 3B, 3B+, 3BL, 4B

Durable Resin

Durable Resin is a pliable, impact-resistant, and lubricious material for squeezable parts and low-friction assemblies. Parts printed in Durable Resin are robust and have low friction, with similar strength and stiffness to polyethylene (PE) and a coefficient of friction is comparable to Delrin® (POM).

*Compatible with Form 2, 3, 3+, 3B, 3B+, 3L, 3BL, 4, 4B

BioMed Elastic 50A Resin

- Soft, elastic, medical-grade material

- Suitable for applications requiring:

- Comfort

- Biocompatibility

- Transparency

- ISO 10993 and USP Class VI certified

- Manufactured in an FDA-registered, ISO 13485 facility

- Appropriate for use in applications for:

- Long-term skin contact (> 30 days)

- Short-term mucosal membrane contact (<24 hours)

*Compatible with Form 3 and Form 4

BioMed Amber Resin for Short-Term Bodily Contact

A stiff, functionally strong medical-grade material for biocompatible parts that require short-term skin and mucosal membrane contact.

*Compatible with Form 3

BioMed Clear Resin for Long-Term Bodily Contact

A medical-grade material designed for rigid, non-brittle, biocompatible parts that require long-term skin and mucosal membrane contact and for end-use medical devices.

*Compatible with Form 3 and Form 4

BioMed Durable Resin 1 L

BioMed Durable Resin is a clear 3D printing material for biocompatible applications requiring impact, shatter, and abrasion resistance. This USP Class VI material can be used in applications for long-term skin and short-term tissue, bone, and dentin contact (<24 hours).

*Compatible with Form 3 and Form 4

General Purpose Resins

General Purpose Resins

- Gresycale Resins for Prototypes and Models: With a matte surface finish, opaque appearance, and precise details, Black, White, and Grey Resins are ready to use right off the printer. Their neutral undertone also makes a great base for parts that will eventually be painted or undergo other finishing processes.*Compatible with Form 3 3D Printers

- Color Base Resin: The first integrated color mixing solution for stereolithography, the Formlabs Color Kit enables 3D printing in 16 colors without the manual work of finishing and painting. Field test product concepts more quickly with 3D prints that fit their environment.

- *Compatible with Form 3 and Form 4

Color Resin V5 — Professional, Vivid Prototypes with a Matte Finish

Formlabs Color Resin V5 is the latest evolution of rapid prototyping resin, engineered for professionals who need highly detailed, aesthetically pleasing models straight off the printer. The new formulation provides a smoother matte finish, enhanced part strength, and improved color mixing—a perfect match for design verification, visual presentation, and fit checks.

Key benefits:

- Matte surface finish for a more refined, professional appearance

- Increased part durability compared to previous Color Resin versions

- Smoother color blending with the Formlabs Color Kit

Grey Pro Resin for Prototypes & Models

With a matte surface finish, opaque appearance, and precise details, Black, White, and Grey Resins are ready to use right off the printer. Their neutral undertone also makes a great base for parts that will eventually be painted or undergo other finishing processes.

*Compatible with Form 3

Clear Resin for Transparent Applications

Stereolithography 3D printing technology makes clear prints possible on the desktop. Clear Resin is great for fluidics and mold making, optics, lighting, and any parts requiring translucency.

*Compatible with Form 3

Draft Resin for Truly Rapid Prototyping

Draft Resin prints up to four times faster than Formlabs standard materials, making it ideal for initial prototypes and rapid iterations to help bring products to market faster. Parts printed with Draft Resin exhibit a smooth grey finish and high accuracy. Use 200 micron settings for fast print speeds, or use 100 micron settings for models with finer details.

*Compatible with Form 3

Jewelry Resins

Jewelry Resins

- Castable Resin was designed to capture precise details and smooth surfaces.

- It burns out cleanly without ash or residue, allowing jewelers and casting houses to go straight from digital design to a 3D print suitable for direct investment casting.

Castable Wax Resin

Castable Wax Resin is a 20% wax-filled material for casting that can capture intricate features and offers a smooth surface finish for accurate castings with zero ash content and clean burnout. It is ideal for ultrafine structures in jewelry, as well as highly accurate patterns for casting and pressing dental prosthetics.

*Compatible with Form 2, 3, 3+, 3B, 3B+, 3L, 3BL, 4, 4B

Castable Wax 40 Resin

Castable Wax 40 Resin is a 40% wax-filled material that offers the easiest workflow on the market for 3D printing and casting challenging, highly detailed designs, from intricate bridal jewelry to large demanding pieces. It supports a wide range of casting conditions and gypsum investments, has low expansion, and burns out cleanly.

*Compatible with Form 2, 3, 3+, 3B, 3B+, 4, 4B

Casting Resins

True Cast Resin — Ash-Free Burnout for Jewelry & Precision Investment Casting

Formlabs True Cast Resin is a cutting-edge material designed for direct investment casting, providing clean, ash-free burnout and incredible print resolution. Whether you’re producing intricate jewelry, small metal parts, or dental applications, this resin delivers outstanding performance with improved workflow simplicity.

Why True Cast Resin?

- Ash-free burnout: Optimized formulation for clean, complete burnout in standard casting environments

- High detail fidelity: Capture fine features, surface textures, and sharp edges with confidence

- Improved casting success rate over previous wax and castable resins

- Compatible with gypsum-bonded investmentsTrue Cast Resin combines the strengths of Formlabs’ past casting resins with enhanced mechanical properties and cleaner performance, making it the go-to solution for professionals in jewelry, industrial casting, and small-scale foundry work.

Clear Cast Resin

Clear Cast Resin is a resin designed for investment casting, to directly print patterns that can be invested and cast. It has an extremely low thermal expansion, low ash, and no trace heavy metals.

Clear Cast Resin, paired with a latticing software, is recommended for use with larger parts, excelling at producing geometries thicker than 3 mm.

*Compatible with Form 3, Form 3+, Form 3B, Form 3B+, Form 3L, Form 3BL, Form 4, Form 4B 3D Printers