Expand and scale into mid-volume production environments

For production environments producing over 200 parts per week

MANUFACTURING PREDICTABILITY

- Quality—from fine detail and sharp edges to textures.

- Dimensional accuracy and repeatability that rivals industrial tooling—faster.

- Functional parts with best-in-class isotropy.

- Optimal yield at industrial-level OEE.

- Maximize your equipment uptime.

BREAKTHROUGH ECONOMICS

- Best-in-class economics and productivity – for production environments.

- Uniquely predictable and consistent print time for any type of part.

- Centralized job tracking and production fleet Streamlined workflow and HP’s most economical continuous 3D printing.

- Flexibility and agility—without injection molding fine-tuning steps.

EXPAND INTO NEW APPLICATIONS AND MARKETS

- Address more final part applications with new levels of repeatable accuracy and best-in-class economics.

- Produce applications with flexible, elastomeric properties with TPU material.

- Deliver a breadth of applications for various markets with HP 3D High Reusability PA 11 and PA 12 materials today, and more in the future.

- Address sustainability, with lower carbon footprint3 parts, and HP 3D materials offering industry-leading reusability.

HP Jet Fusion 5200 Series 3D Printing Solution

HP Jet Fusion 5200 3D Printer, Build Unit, Natural Cooling Unit and Processing Station.

Materials

HP 3D High Reusability PP enabled by BASF

Chemical resistant, weldable,low moisture absorption,functional parts

HP 3D High Reusability PA 11

Ductile, quality parts

HP 3D High Reusability PA 12

Strong, quality parts at a low cost per part

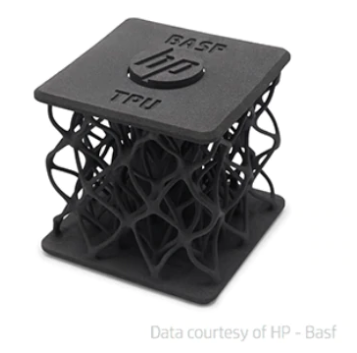

BASF Ultrasint 3D TPU01

Produce flexible, functional parts

HP 3D High Reusability PA 12 Glass Beads

Stiff, dimensionally stable, quality parts.