Meet the MfgPro236xs

- 60 Watt Laser

- 230x230x250mm(9′ x 9′ x 10″) Build Volume

- 10% Larger Build Area

- Materials PA6, PA6FR, PA11, Carbon Fiber, PA12, TPU, FibreTuff

- Fastest Cooling Cycle in SLS

- 20% Powder Refresh Rate for PA12, TPU

- Open Material Platform

- White Parts Easily Dyed Vibrant Colors

- 12 Month Warranty Included – Extended Warranties Available

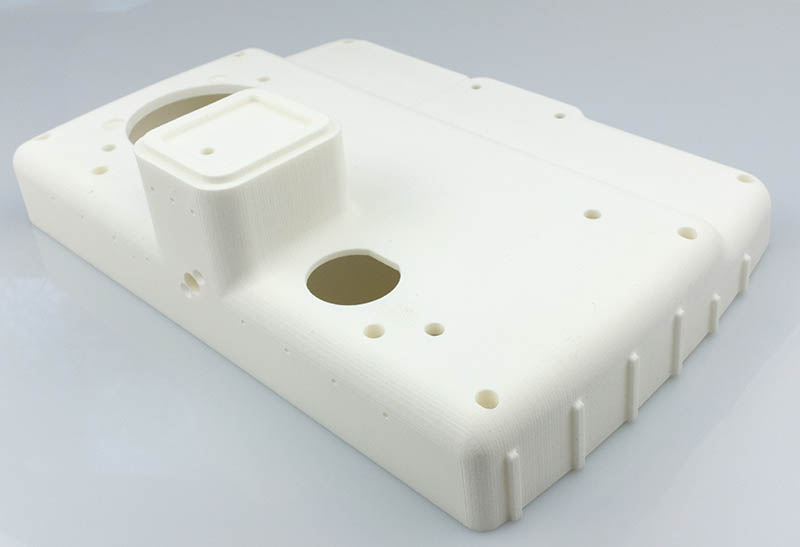

Create Stronger Parts and Reduce Production Time with XYZprinting’s SLS Technology

The MfgPro236xS uses CO2 Selective Laser Sintering technology (SLS) to give users the ability to print in various plastic materials to produce a wider selection of engineering parts. The MfgPro236xS lays down a layer of thermoplastic material and fuses the plastic material with a laser. The result is a print that rivals injection molding products regarding strength and precision.

No Support Material Needed

With SLS technology, the thermoplastic material serves as the support material, thereby eliminating the need to design and print additional support materials. The printing process uses less material and the printed product is left undamaged. Multiple models can be stacked and printed in any orientation as well, ensuring that every print job counts.

Shorten Production Times

The MfgPro230 xS print speed reaches up to 1 liter per hour, making the printer perfect for small business production and engineering design processes. The printer helps shorten design verification processes, allowing users to quickly realize product concepts during the design and development (D&D)stage, reduce D&D costs, and accelerate the entire process.

Intuitive Software

The MfgPro230 xS uses two software suites, SLS Build and SLS Ware; SLS Build allows a user to directly operate a model sintering process on the printer and SLS Ware allows the user to remotely plan sintering projects on the printer and check printing files.

Removable build tray module for high productivity

The removable build tray module in the MfgPro230 xS lets users print more efficiently. By removing the build tray, users can clean off their prints while placing a new build tray directly into the machine to start a new print immediately. The removable print tray provides a cleaner solution for powder removal and a more efficient method for printing.