Nexa3D materials are tailored to the LSPc process delivering speed, durability and accuracy. Getting the most out of our proprietary LSPc technology requires a unique combination of chemical and physical properties from our resins. These carefully crafted resins are ideal for a wide range of applications ranging from rapid prototyping, jigs and fixtures all the way to low volume high mix manufacturing.

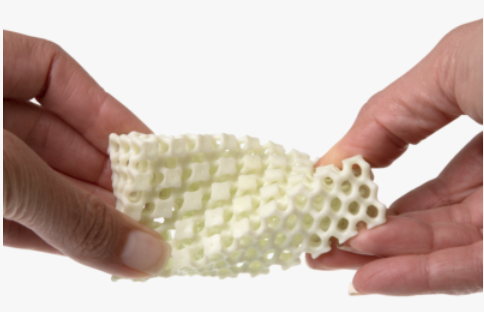

NEW! xFLEX White

|

A medium-soft rubber-like material that cures to a soft, elastomeric material. Customers can use this industrial-strength material in applications that require resilience, snapback and tear resistance, such as pipes and manifolds, handles and grips, seals and gaskets or sportswear and footwear midsoles. This material also boasts an impressive 150 percent elongation at failure, an excellent energy return of up to 50 percent and is resistant to most solvents.

Unique Features

Use Cases and ApplicationsResilience, Snap back and Tear resistance elastomeric application |

NEW! x45-Natural |

x45-Natural is a tough material that is ideal for models and functional prototypes requiring high strength and durability. Capable of much higher print speeds than current materials, x45-NATURAL features excellent out-of-printer properties with robust print styles to ensure high first-time build success. Supporting a wide variety of applications with short processing times, x45-NATURAL’s draft build mode enables companies greater flexibility within their manufacturing processes.

Unique Features

Use Cases and ApplicationsA clear tough semi-rigid material with high-strength engineering plastic with similar performance to unfilled propylene delivering good impact resistance. The material is ideal for a wide variety of design, engineering and manufacturing of end use parts for packaging, piping, consumer and industrial applications including large housings and enclosures.

|

NEW! x45-Clear |

Combines good clarity with toughness for a wide variety of models and functional prototypes requiring fast turnaround times. x45-CLEAR has outstanding build speed to give companies greater adaptability within their manufacturing processes. x45-CLEAR has excellent out-of-printer properties with robust print styles to ensure high first-time build success.

Unique Features

Use Cases and ApplicationsA clear tough semi-rigid material with high-strength engineering plastic with similar performance to unfilled propylene delivering good impact resistance. The material delivers an attractive industrial black finish and is Ideal for a wide variety of design, engineering and manufacturing of end use parts for packaging, piping, consumer and industrial applications including large housings and enclosures.

|

NEW! x45-Black |

A durable material that features an attractive matte black finish for parts such as automotive components that are usually molded in black plastic. It combines build speed and excellent out-of-printer properties ensures first-time build success, giving manufacturers greater flexibility within their output processes.

Unique Features

Use Cases and Applications

|

xPP405 Black and xPP405 Clear |

A tough semi-rigid material with high-strength engineering plastic delivering good impact resistance with performance similar to unfilled propylene. Suitable for applications such as large housings, sheet metal forming dies, and see-through element.

Unique Features

Use Cases and ApplicationsA clear tough semi-rigid material with high-strength engineering plastic with similar performance to unfilled propylene delivering good impact resistance. The material delivers an attractive industrial black finish and is Ideal for a wide variety of design, engineering and manufacturing of end use parts for packaging, piping, consumer and industrial applications including large housings and enclosures. |

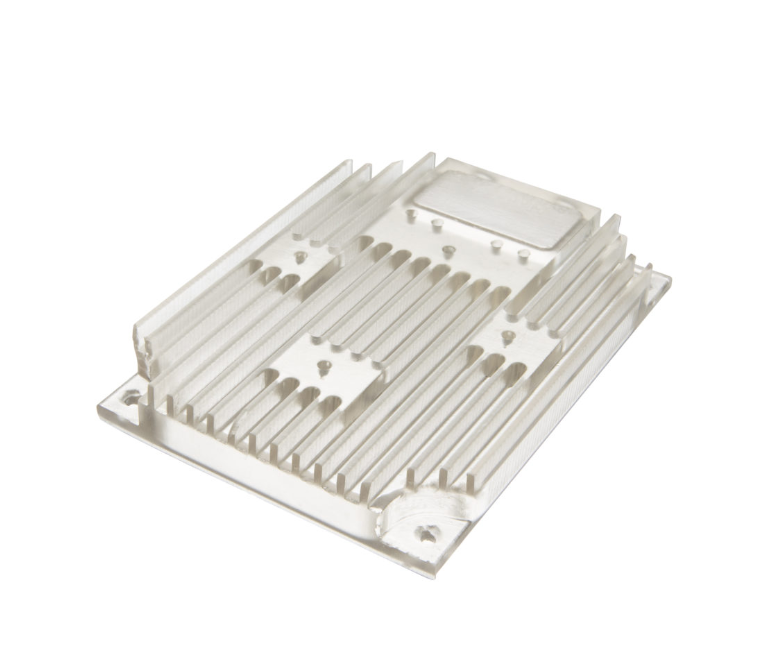

xPEEK147 Black |

NEW! xPEEK147 BlackA tough material with excellent surface finish, strong dimensional stability and temperature resistance up to 230°C. Suitable for applications, such as tooling, molding applications, automotive under-hood, and a variety of end-use parts. Unique Features

ApplicationsTough material in the performance range of PEEK designed for production parts, tooling and molding applications, due to its high temperature resistance withstanding up to 230°C and very high stiffness. |

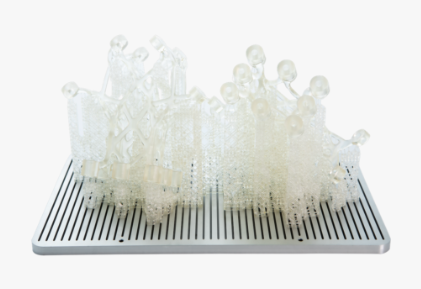

xCast |

xCast delivers precision patterns for rapid prototyping and series production that seamlessly integrate into any production foundry’s dip-shell or flask-type investment casting process delivering toolless semi-hollow plastic patterns in lieu of wax patterns. xCast patterns are processed similarly to wax without autoclave and are flash fired from the ceramic mold. Featuring low ash content, xCast can be used to create high-resolution parts with excellent surface finish

Unique FeaturesIdeal for in foundry series production of small, large and complex metal parts. ApplicationsAerospace |

xPRO410 |

xPRO410 is a rigid photoplastic that prints parts with extreme accuracy and an exceptional surface finish. Formulated based on Henkel’s LOCTITE® PRO410 polymer and optimized for Nexa3D’s NXE400 3D printer, the material is ideal for general purpose prototyping and series production. xPRO410 is perfect for printing fast and accurate parts for a wide range of form, fit, and function designs, beautiful appearance prototypes, and functional parts. xPRO410 can be printed continuously on the NXE400 at speeds of up to 8 liters per hour, representing a 20X productivity gain. xPRO410 parts achieve dimensional accuracy of within 0.2% after post-curing on the Nexa3D xCure system, and can withstand temperature exposure of up to 70°C.

Unique FeaturesxPRO410 is the most affordable general-purpose material on the market, enabling multiple daily design iterations and same-day on-demand production parts for small and large product enterprises. ApplicationsExcellent for all aspects of ultrafast general-purpose prototyping including, form, fit, and function design iterations. Prints outstanding appearance models. Ideal for packaging applications and series production of rigid parts. |

xMED412 |

xMED412 is polypropylene-like material that is ideal for manufacturing a variety of biocompatible, medical and wearable devices. xMED412 is based on Henkel’s Loctite® MED412 material and is covered by all of its associated clearances, tests and certifications.

xMED412 is developed to deliver highly consistent part performance with extraordinary functionality. The medical-grade material is a very strong and durable photopolymer with mechanical attributes similar to polypropylene with fantastic elongation, impact strength, and compression strength. Unique FeaturesHi impact polypropylene-like performance Use Cases and ApplicationsBiocompatible, medical and wearable devices: orthotics guides, braces ventilator parts and respirators |

xCLEAN |

xCLEAN washing Solvent for All Resin-based 3D PrintersxCLEAN is an effective and environmentally friendly washing solvent that is designed to work consistently with most photopolymer 3D printers and resin systems available on the market. xCLEAN has three times the saturation limit of IPA, meaning less waste and fewer changeovers for additive manufacturers. xCLEAN is safer to handle than other cleaning solvents and does not require any special storage or adherence to shipping regulations typically associated with post processing photopolymeric parts. Compatible with most cleaning systems on the market, xCLEAN is made from smaller molecules than TPM or DPM, eliminating the greasy residue that is typically associated with these alternatives. xCLEAN can be easily recycled and recovered with a vacuum-assist solvent distillation unit, and it is compatible with most automated washing units on the market today including closed loop systems. xCLEAN is not cleared for use when cleaning parts printed from biocompatible resins, and customers are advised to closely follow wash recommendations to preserve the material’s biocompatibility. Unique FeaturesSustainable: Lasts 3X longer than isopropyl alcohol with less waste and fewer changeovers |

xCE-White |

xCE-White – FunctionalHigh performance polymer for producing end-use plastic parts and injection molding tools in minutes. Nexa3D’s new material is the fastest single cure polymer boasting higher flexural strength compared to those typically achieved only in dual cure cyanate ester resins. xCE-White has excellent isotropic properties and exhibit long-term environmental stability. xCE-White is used to produce injection molding tools for a wide range of thermoplastic polymers including PP, PE, HDPE and PETG. Molds printed from xCE-White were successfully injected hundreds of times at temperatures between 230°C and 280°C without any visible mold temperature degradation or adhesion, and without the use of any mold release agents. Unique Features

|

xCE-Black – Functional |

Unique FeaturesFastest Printing Speed in it’s class Rapid IterationsForm, fit and function analysis |

xGPP-Translucent – TOUGH, ACCURATE, FAST |

Unique FeaturesNo Water uptake Functional end use partsAir duct |

xGPP-Gray – High detail, Great surface finish |

Unique FeaturesGreat surface finish Form, fit and function analysisDemonstration & Communication |

xGPP- Blue – DRAFT – LIGHTNING SPEEDS |

High-performance polymer for producing end-use plastic parts and injection molding tools in minutes. Nexa3D’s new material is a single cure polymer that delivers higher flexural strength compared to those typically achieved only in dual-cure cyanate ester resins. xCE-Black has excellent isotropic properties and exhibits long-term environmental stability.

xCE-Black is used to produce injection molding tools for a wide range of thermoplastic polymers including PP, PE, HDPE and PETG. Molds printed from xCE-Black were successfully injected hundreds of times at temperatures between 230°C and 280°C without any visible mold temperature degradation or adhesion, and without the use of any mold release agents. Unique FeaturesHigh performance accurate |

3843-xABS Black – Functional |

High performance, high modulus material that boasts excellent flexural and tensile physical properties with a relatively high degree of elongation. 3843xABS (Powered by LOCTITE®) Black displays high green strength and excellent heat deflection temperature, enabling it to print accurately and function in a wide variety of applications including mechanical assemblies for robotics and automation machinery, bracket, levers and arms for manufacturing stations, and a variety of drones and last mile transportation vehicles parts and assemblies.

Unique FeaturesHigh performance ApplicationsMechanical assemblies (robotics, automation machinery, bracket) |