Print a Model Every 49 Seconds with Fast Model Resin From Formlabs

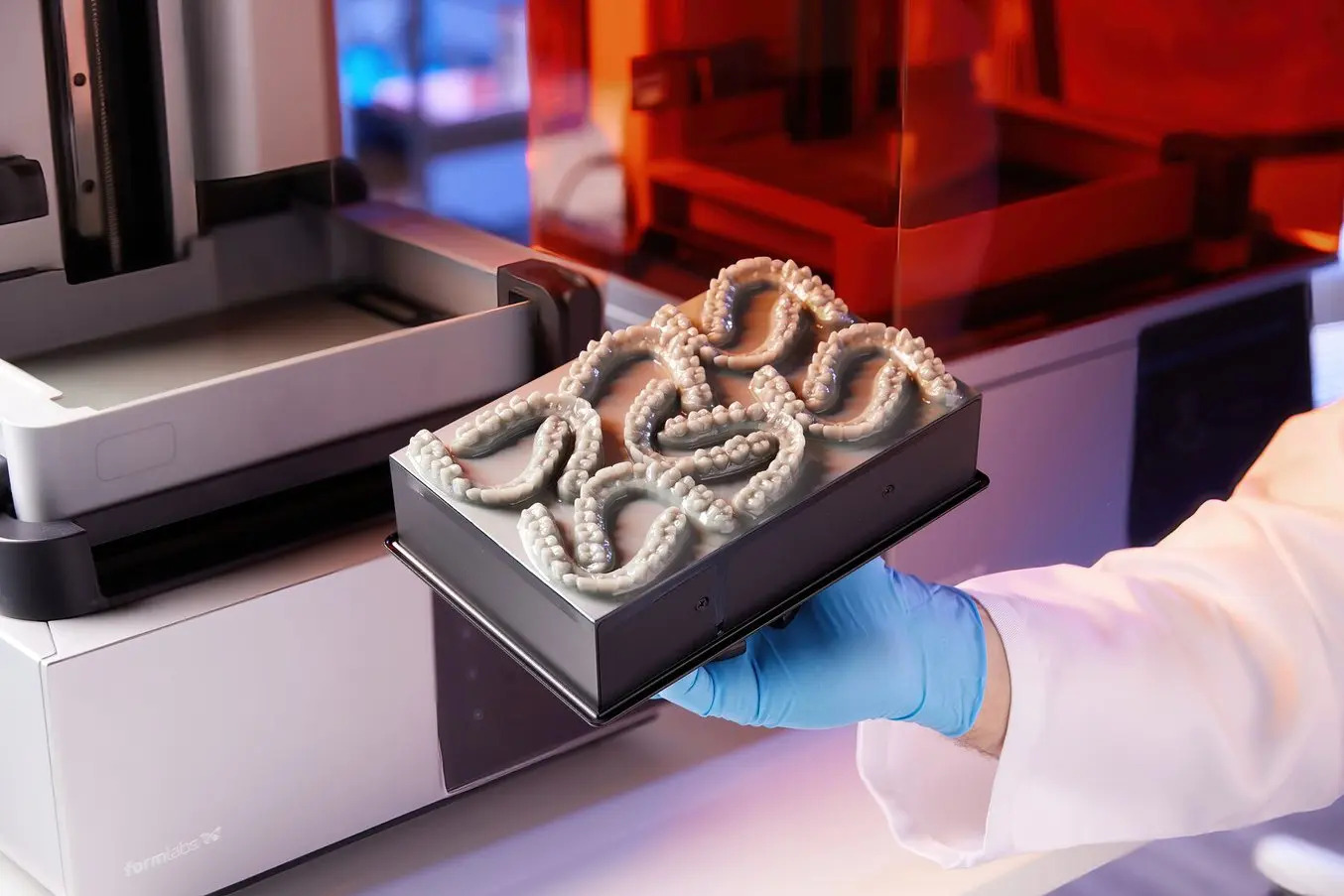

The Form 4B 3D printer and Fast Model Resin revolutionize dental printing by enabling the production of 11 models in just nine minutes. This combination optimizes speed without compromising accuracy, enhancing workflow efficiency and maintaining high mechanical performance.

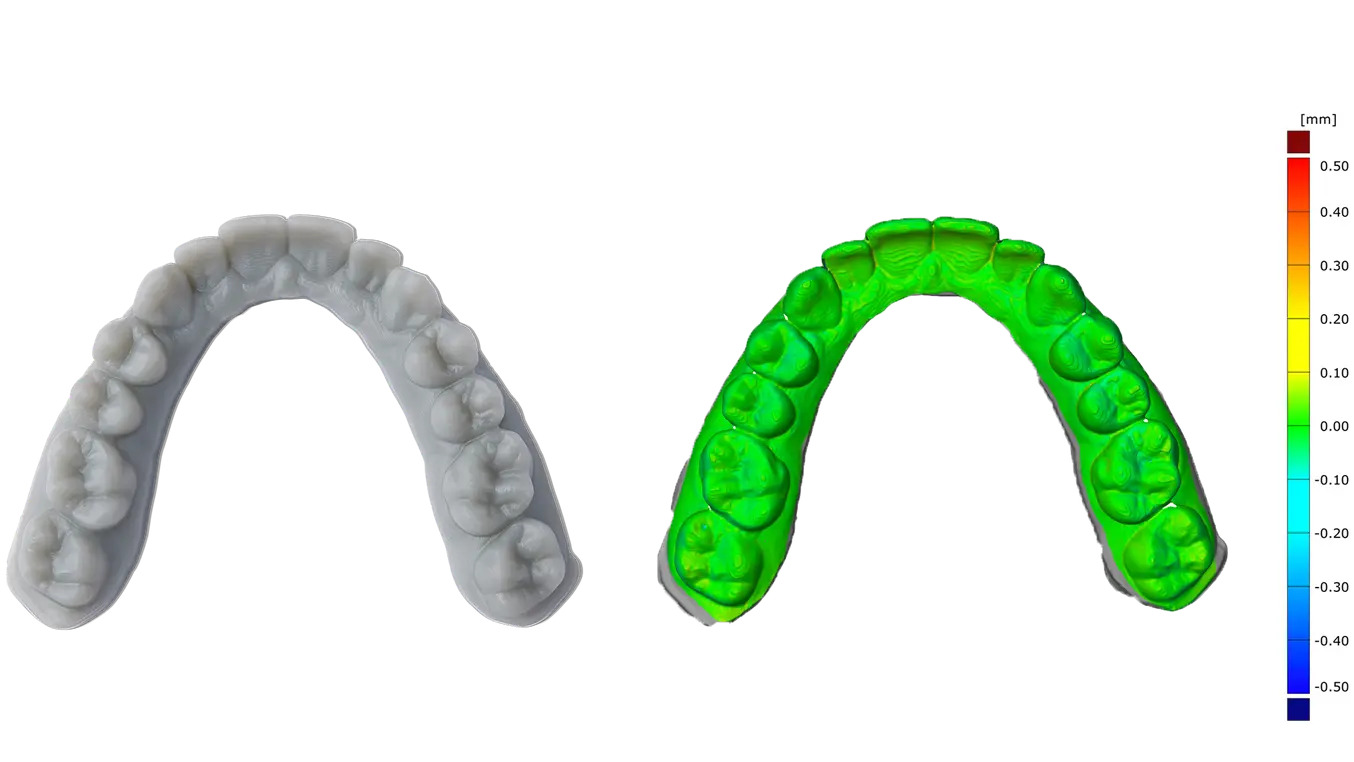

Fast Model Resin stands out with its improved aesthetics, offering a more opaque and matte finish compared to Draft Resin. It’s ideal for thermoforming applications, balancing speed and accuracy to ensure appliances fit patients correctly. The resin supports continuous printing, producing over 60 arches per hour with efficient post-processing.

PreForm Dental software allows users to customize layer heights and printer settings, balancing accuracy, resolution, and speed. For detailed cases, a 100 μm layer height captures critical details, while the 160 μm Fast Arch setting is optimal for aligners. Dental professionals have successfully used these settings to achieve desired speed and accuracy.

Feedback from professionals highlights the resin’s utility in both dental labs and practices. It supports same-visit dentistry and efficient production of aligners, with quick post-processing times enhancing workflow efficiency. Fast Model Resin’s superior mechanical properties make it a preferred choice for thermoforming models.

Want to learn more about Formlabs Materials? Contact us below:

This abridged article was created with the use of AI. For the full version, written by Formlabs, please read it on Formlab’s website here: Print a Model Every 49 Seconds With Fast Model Resin Formulated for Industry-Leading Speed and Accuracy | Formlabs Dental

Leave A Comment