Lockheed Martin Space uses METHOD X to create parts for the lunar rover project, enabling the engineers to design, develop, and test autonomous systems and processes

Lockheed Martin is a global aerospace and defense company, with the mission to connect, protect and explore. The company focuses on next-generation and generation-after-next technologies. In alliance with General Motors, Lockheed Martin is developing a new fully-autonomous lunar rover that could be used for NASA’s Artemis program. This is a fitting team that pays homage to the original Apollo rover, which GM was also involved in its development.

Some elements of the rover’s autonomy system’s early design and development is done at Lockheed Martin’s state-of-the art R&D facility in Palo Alto, Calif., the Advanced Technology Center (ATC), which is well-equipped with a variety of cutting-edge technology, including a lab full of 3D printers. MakerBot 3D printers have been in use for about five years and have provided easily accessible 3D printing for a host of projects for Lockheed Martin’s team of engineers.

Lockheed Martin’s Advanced Technology Center is a major hub for developing next-generation space technology.

ULA rockets commonly carry space-going payloads like the satellites being developed at the ATC.

“A lot of what we’re able to help with at the 3D printing lab at ATC is really enabling our engineers to create a range of applications, like test beds, sensor mounts, and prototypes, that further advance the technologies we’re working on,” said Alyssa Ruiz, research engineer and lab manager, Lockheed Martin Advanced Technology Center.

Prototyping is always an important part of the design process because it allows engineers to test in a real-world environment before going into production—which in aerospace means manufacturing low-volume products with inexpensive materials. Finding issues later in production could mean expensive costs and time overruns.

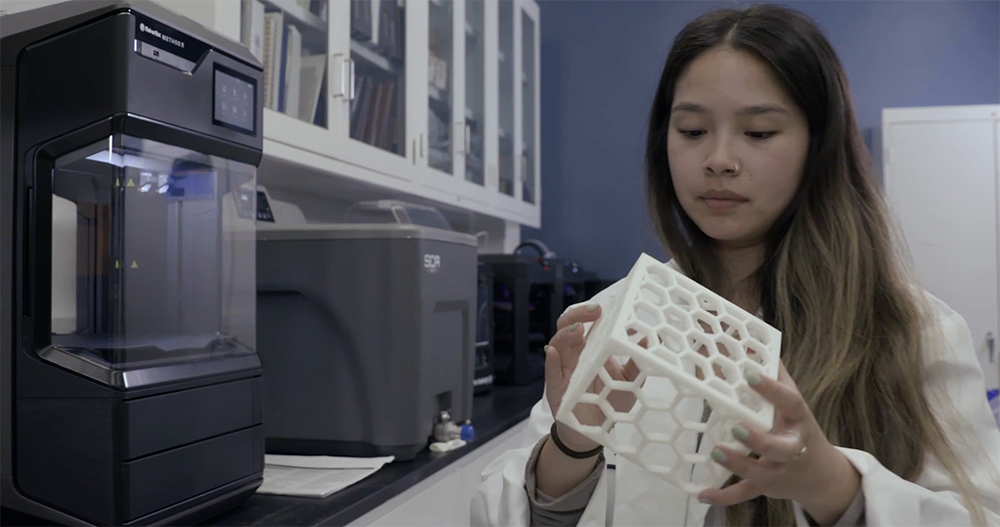

Alyssa Ruiz inspects a 3D-printed electronics housing printed on METHOD X in the ATC’s 3D printing lab.

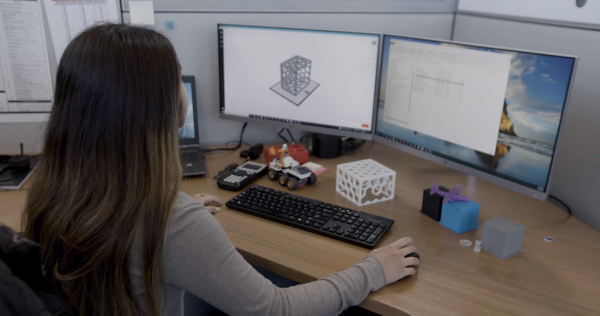

3D printers are capable of creating parts on-demand with little to no manual labor – straight from a CAD file, making them the ideal tools for prototyping. Printed prototypes are quick and easy to iterate on with very little cost. Prototyping through an external shop or service bureau could cost 10x more to make and take 10x longer to get the part in hand.

“There’s a huge benefit to having the 3D printers on site. Without them, we would have to send parts out for machining, which can extend lead times and increase costs. The 3D printers at our lab help with the efficiency of prototyping, getting parts out, and making sure that we can meet schedules and budgets,” said Ruiz.

With customers asking for faster iterations and quicker technology insertions, Lockheed Martin had to quickly adapt to these increasing demands. Digital transformation is allowing the company to accelerate these changes, and 3D printing is one of those strategies that is enabling it.

The Artemis Lunar Mission will likely launch from Cape Canaveral in the near future.

The latest addition to the ATC’s 3D printing lab is the MakerBot METHOD X 3D printing platform. With METHOD X, the team can print parts in materials like Nylon Carbon Fiber and ABS giving them the performance they need for accurate testing—and thanks to METHOD X’s heated chamber, the parts are dimensionally accurate without the variable warping that comes with a typical desktop 3D printer.

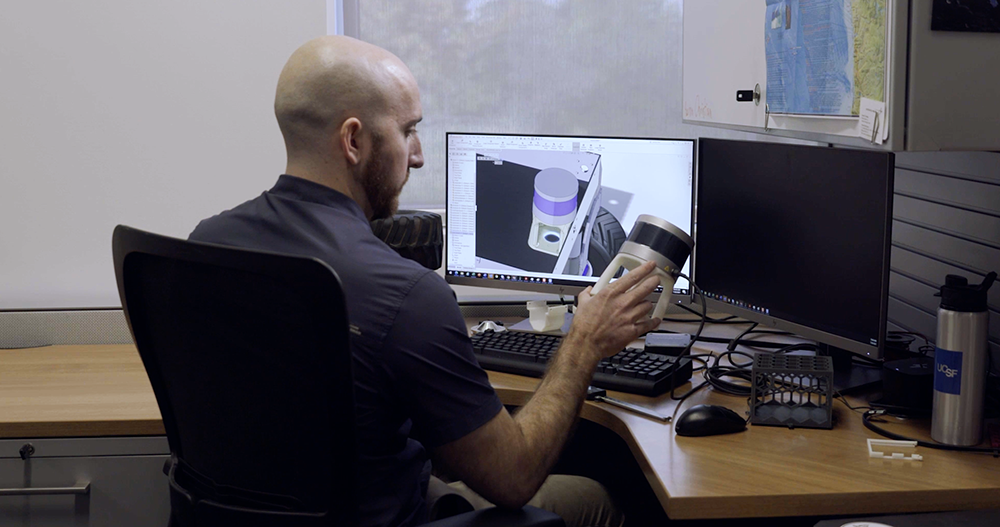

“At ATC, we have multiple MakerBot printers that help with quick turnaround times,” said Aaron Christian, senior mechanical engineer, Lockheed Martin Space. “I will design a part, print it, and have it in my hand hours later. This allows me to quickly test the 3D-printed part, identify weak points, adjust the model, send it back to print overnight, and then have the next iteration in the morning. 3D printing lets me do fast and iterative design, reducing wait times for a part from weeks to hours.”

Aaron Christian compares his 3D-printed LIDAR sensor mount with his digital CAD model.

Lockheed Martin engineers are testing a multitude of applications designed for the lunar rover. Christian and his teammates are using METHOD X to print a number of parts for prototyping and proof of concept for the rover project, including embedded systems housing, sensor mounts, and other custom parts. “The MakerBot METHOD X produces dimensionally tolerant parts right out of the box – and for all sorts of projects, you can print multiple parts that can mate together.”

Many of these parts are printed in MakerBot ABS and designed to withstand desert heat, UV exposure, moisture, and other environmental conditions. In combination with Stratasys SR-30 soluble supports, parts printed with MakerBot ABS are designed to provide a smoother surface finish compared to breakaway supports. Printing with dissolvable supports also enables more organic shapes that would have been otherwise impossible to produce through traditional machining. 3D printing encourages engineers to think more outside of the box than they have ever before.

“We’re in the very early stages of development and the rover we have at ATC is a testbed that we designed and developed in-house. This affordable modular testbed allows us to make quick changes using 3D printing to change the design for other applications, whether it be military, search and rescue, nuclear applications and just extreme environment autonomy needs,” said Christian.

The next lunar rover will need to operate autonomously as well as at the controls of astronauts while withstanding the harsh conditions of space.

Ruiz prepares a CAD file for an overnight print using MakerBot Print

3D printing lets the team test parts affordably, iteratively, and modularly. One of the parts printed for the rover was a mount for a LIDAR, a sensor that can help determine the proximity of objects around it. Broadly used in self-driving vehicles, Lockheed Martin uses LIDAR in a lot of its autonomy projects. The mount was designed to sit on the rover, a completely modular robot system, so it was printed in ABS which allows it to handle more extreme conditions than typical PLA. The mount also allows engineers to continuously swap out the LIDAR with different sensors, such as a stereo camera, direction antenna, RGB camera, or a rangefinder. It has a complex organic shape to it, which can be difficult to achieve via traditional machining. The mount also has a lot of access to ensure proper airflow to keep the part cool and temperature-regulated on the robots.

The imbedded electronics housing is designed to go inside the rover or in other robots at the ATC. The housing was developed to protect the electronics from anything that could potentially fall on them. Although it was printed in PLA, due to its hexagonal shape, it offers solid strength. Its design also lends itself well to the open airflow needed to cool down the system while still protecting the device.

In addition to printing prototypes, Lockheed Martin is using 3D printing for production parts that will go into various space-going platforms.

“A big advantage for testing and flying 3D-printed parts for space applications is that it simplifies the design. You can create more complex shapes. It reduces the amount of fasteners needed and part count, which is a huge cost savings because that’s one less part that has to be tested or assembled,” noted Christian. “This also opens up for future in-situ assembly in space. You have designed, printed, and tested the part on Earth. Now you know that, in the future, you can 3D print that same part in space because you have shown that the material and part works there.”

Manufacturing in space is expensive but appealing for future applications and missions. Now, bulk materials can be flown into space to be used to 3D print multiple parts and structures, rather than flying each part out individually. Combining that with a digital inventory of part files, 3D printing in space reduces costs by cutting out the need for storage and multiple trips, which make it expensive to fly.

“The digital inventory concept helps push our digital transformation forward—you have digital designs that you can ship up, where you just print the parts and have them assembled on location,” added Christian.

Leave A Comment