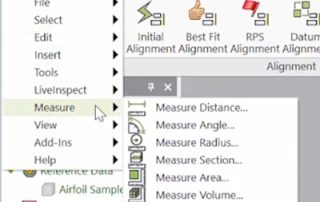

The Various Control X Measure Functions

There are many different measurement functions that can be used in Control X Professional. This post will explain what they are and how to use them. We will use the airfoil example above to illustrate the various Control X measure functions available. In the menu below you will find a list of the measurement tools that are available within Control X. These all apply to just the MEAsured data. The Measure Distance function allows you [...]