Understanding Refresh Rate in SLS 3D Printing

Selective Laser Sintering (SLS) 3D printing is a powerful technology that allows for the creation of high-quality, industrial-grade parts. One of the key factors in achieving optimal print quality and efficiency with SLS printers, such as the Formlabs Fuse Series, is the refresh rate. The refresh rate refers to the ratio of new powder to recycled powder used in each print cycle. This balance is crucial because it impacts both the material properties of the printed parts and the overall cost-effectiveness of the printing process1.

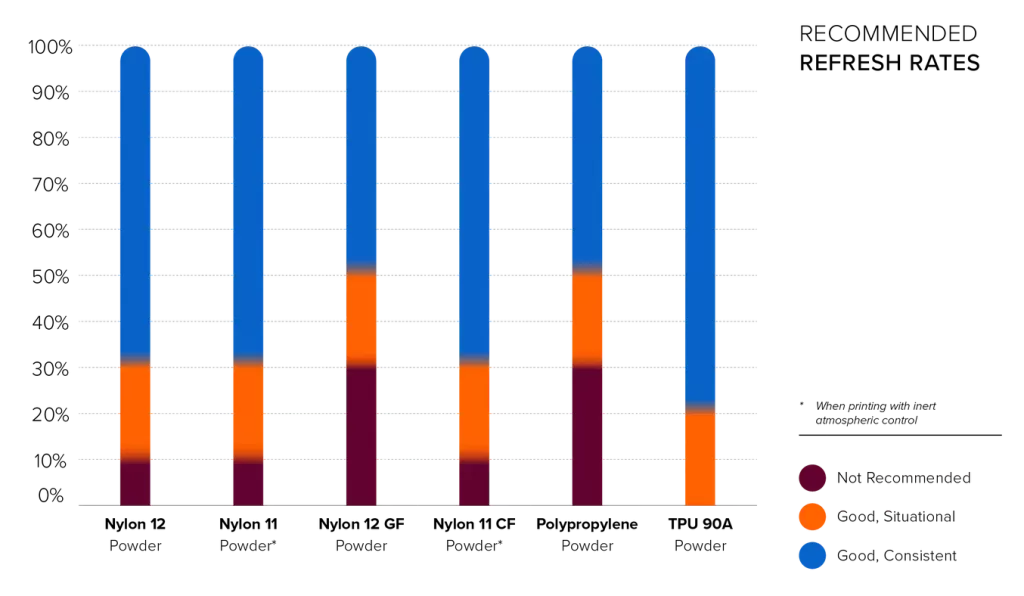

The refresh rate is adjustable, allowing users to fine-tune it according to their specific needs and workflows. For instance, a 100% refresh rate means using entirely new powder, while a 0% refresh rate would use only recycled powder. However, using recycled powder over many cycles can degrade material properties, so finding the right balance is essential. Formlabs provides recommended refresh rates for their SLS powders, but users can tweak these settings to optimize their processes1.

Choosing the right refresh rate involves considering several factors, including packing density—the arrangement of parts within the build chamber. Higher packing densities mean less unsintered powder, which can be recycled more efficiently. For example, if the packing density is 30%, a refresh rate of 30% would ideally result in no excess used material, making the process more cost-efficient and reducing waste1.

Formlabs’ Fuse Sift and PreForm software play a significant role in managing the refresh rate and recycling process. The Fuse Sift helps in the post-processing stage by separating and recycling unsintered powder, while PreForm software assists in planning and optimizing the print job. Together, these tools help users maintain the right refresh rate and ensure high-quality prints with minimal waste1.

In conclusion, understanding and managing the refresh rate in SLS 3D printing is vital for achieving the best results. By balancing new and recycled powder, users can optimize their printing processes, reduce costs, and produce high-quality parts consistently. The flexibility to adjust the refresh rate according to specific needs makes the Formlabs Fuse Series a versatile and efficient choice for industrial 3D printing1.

Contact us for more information:

To learn about Formlabs new Nylon 12 Powders; Tough and White, visit here:

This abridged article was created with the use of AI. For the full version, written by Formlabs, please read it on Formlabs website here: Understanding Refresh Rate in SLS 3D Printing | Formlabs

Leave A Comment