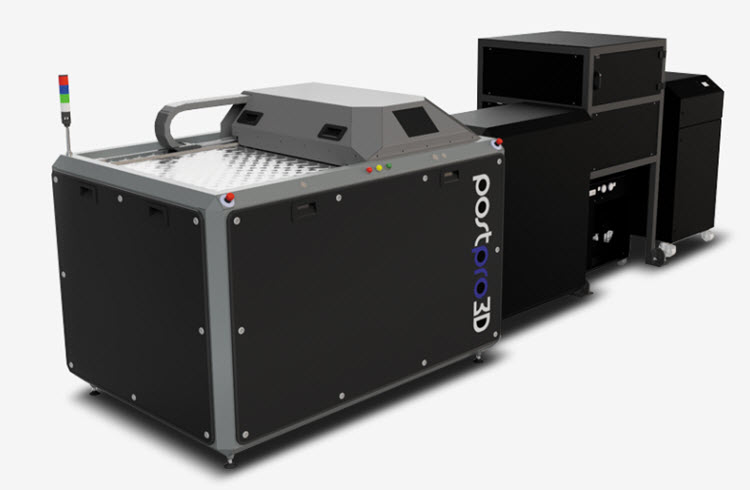

The patented PostPro3D® technology is an automated post processing solution for smoothing thermoplastic polymer 3D parts. PostPro3D® achieves an injection molded surface quality on parts printed using Laser Sintering, HP Multi Jet Fusion, High Speed Sintering, or Fused Deposition Modelling technology.

PostPro3D® is an enabling technology based on AMT’s proprietary BLAST™ process (Boundary Layer Automated Smoothing Technology) and reduces lead-time, cost of manufacture, operational and maintenance costs providing the ‘missing piece’ in the digital manufacturing chain.

The patented PostPro3D Mini offers all the advantages of the PostPro3D® machine, but in a more compact unit for smaller production runs, STEM programs and design studios.

KEY FEATURES / CAPABILITIES

- BLAST Automated

- Smoothing and surface modification

- Most 3D printing polymers

- Modular

- Size configurable

- WaterlessRecyclable, single, non-toxic agent

AMT’s patented technology is a smart and automated post processing solution for thermoplastic polymer 3D Printed parts based on AMT’s proprietary BLAST™ process (Boundary Layer Automated Smoothing Technology).

The BLAST Process is now also available in the PostPro3D™ Mini. PostPro3D™ Mini delivers the same quality as the already proven PostPro3D, achieving a surface finish that matches injection molding techniques. This enabling technology reduces lead-time, cost of manufacture, operational and maintenance costs providing the ‘missing piece’ in the digital manufacturing chain.

Our PostPro3D™ Mini makes part surface finishing cost and speed competitive at lower volumes

THE ONLY PATENTED MEDICAL GRADE SMOOTHING SOLUTION FOR ADDITIVE MANUFACTURING

SYSTEM DESCRIPTION

- 10 channel, continuously purged Mass Spectrometer with measurement log and audible alarm for solvent detection

- Extracted lid

- Extraction Air Flow Monitors for detecting an Extraction failure

- Extracted BLASTX Locking Storage Cabinet

- Machine status Traffic light beacon

- Locking machine panels

- Password Protected – operator / engineer / admin levels – User must log in to use the machine, traceable

- Process log (including which operator used the machine) and error history

- Mitsubishi OPC UA Connection Ready – can connect to a MES

- 360 programmable Recipes