SLA 3D Printing Workflow

Streamline your 3D printing process and work more efficiently with our automated, large format post-processing machines. All SLA printed parts require washing to remove residual resin and most benefit from post-curing to achieve maximum material properties.

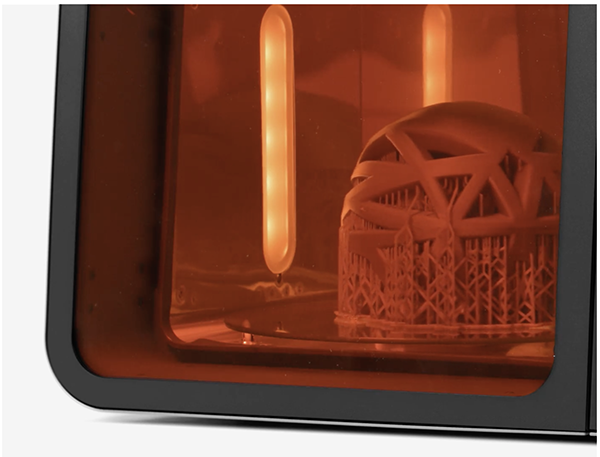

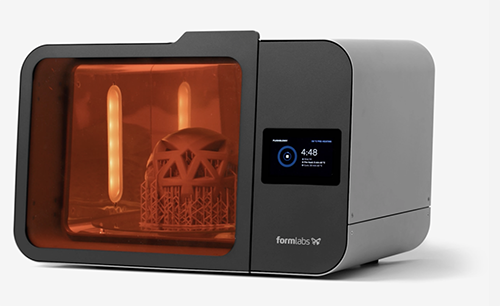

Print your parts on a Form 3L or Form 3BL 3D printer.

Wash

Insert the build platform directly into Form Wash L after printing for a consistent, automatic rinse.

Cure

Transfer the part to the Form Cure L to maximize material properties and ensure peak dimensional accuracy.

After removing any supports, parts are ready for use.

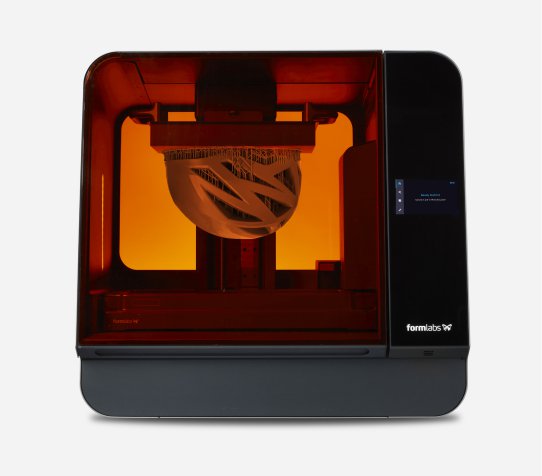

Build Platform 2L

Build Platform 2L with patented Quick Release Technology allows you to quickly and

easily remove 3D printed parts from the build platform without tools in seconds.

Streamline your post-processing workflow with instant and flawless part removals.

Compatibility

● Printer compatibility: Form 3L, Form 3BL

Optimized for Formlabs Materials

Rapid, High-Intensity Curing