3D Printing: Disrupting Disruptive

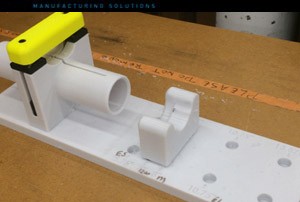

3D Printing is not disruptive. I’ll admit I see how the term came about. Subverting the status quo, hacking our minds and disrupting stagnant industries have become battlecries–and for good reason. Those can all be important topics and help us keep thinking of fresh ways to approach problems. But personally, I don’t think we have to be so obnoxious or contentious about it. We don’t have to go into companies, slam the big red button, and halt operations to introduce 3D printing because the truth is that after working with hundreds of different companies, all using 3D printing in various professional settings, I don’t see much disruption. I don’t hear the manager saying, “Thanks to you I had to lay off a dozen workers because this machine took their job.” I see solutions where no one realized there was a problem. I see dozens of tweaks to processes people didn’t know could get better. For instance, the image to the right is a picture of a fixture that was made when workers at a plant frequently hurt themselves while cutting foam tubes. Having a 3D printer they were able to quickly model up this fixture and print it. Since it was such a [...]

SODIMAS Elevators 3D Printing Prototypes

Stratasys FDM 3D Printed prototype part on left is tested for form, fit and function before final part (on right) is produced Established in 1975, in Valence, France, SODIMAS designs and manufactures high end custom elevators. SODIMAS solutions can be adapted to all architectural styles and projects due to the quality of the materials used and their carefully designed finishing. “Because SODIMAS is focused on the niche elevator business, developing relatively small series of customized solutions, we need to innovate a lot and that’s why Stratasys 3D Printing Solutions are so important to our company,” explains Patrice Arnoult, General Manager, SODIMAS. Spearheading this innovation is the company’s FDM-based Fortus 450mc 3D Printer from Stratasys, which is being used for three primary applications: functional prototyping, assembly tools, as well as sales tools and teaching aids. Cutting Prototype Production Time by 98% “All of our elevator cabins are made from aluminum, but the concept and development for the frames is achieved using Stratasys 3D printing solutions,” explained Stéphane Réau, Deputy Technical Director. “We design and produce the parts that are used to assemble the elevator’s ceiling, walls and floor, simultaneously. Once we’ve 3D printed each part, we’re able to quickly check the design [...]

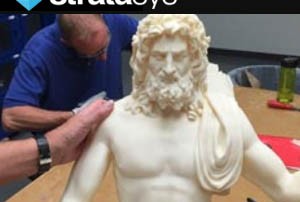

Zeus Returns to Throne with 3D Printing

A fifth-century BC Greek statue, so massive and revered it was tagged as one of the “Seven Wonders of the Ancient World,” is being replicated – slightly smaller – by Stratasys 3D printers. The 3D printed version of the Statue of Zeus at OIympia, based on the original created by the sculptor Phidias in 422 BC, will be the centerpiece of a new exhibit at Atlanta’s Millenium Gate Museum, timed for the opening of the 2016 Olympics. Entitled “The Games: Ancient Olympia to Atlanta to Rio,” the exhibition opens August 20, 2016 and runs until January 2, 2017, and it features Greek artifacts from The Hearst Castle Collection in San Simeon, California, and the Michael C. Carlos Museum in Atlanta, Georgia. CAD rendering of the Zeus statue which is returning to its former glory with the help of the Stratasys Fortus 900mc Production 3D Printer. The original statue, to honor the mightiest Greek god, Zeus, was planned and constructed at the temple in Olympia over the course of more than a decade. It was designed on a wood frame with gold and ivory panels and stood at over 40 feet tall. The statue kept watch over the temple for about 800 [...]

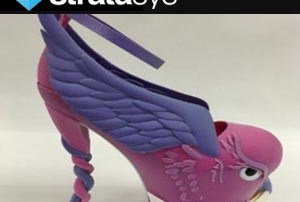

3D Print Fancy Footwear

Stratasys and FFHK Inspire Hong Kong Designers to 3D Print Fancy Footwear Witch Avatar produced on a Stratasys J750 multi-material, full- color 3D Printer, photo courtesy of FFHKHigh-tech Hong Kong will get an infusion of color and creativity next week, as local designers have an opportunity to 3D print selected pieces of footwear on the world’s first multi-material, full-color 3D printer, the Stratasys J750. Organized by the Hong Kong Federation of Footwear Ltd. (FFHK) and the Hong Kong Trade Development Council (HKTDC), the annual Footwear Design Competition aims to enhance and promote the creativity as a stepping stone to the international footwear market. “These shoe models are excellent samples of what we believe 3D printing is capable of, breaking the barrier to create complex designs that has previously challenged the technicality of hand-crafted footwear designs. Some of the designs could hardly be produced due to the inorganic and complex shapes,” said Steven Au, Vice President of the Federation of Hong Kong Footwear Ltd. The Stratasys J750 features PolyJet 3D printing technology, up to 360,000 colors and a wide range of digital materials. God of Thunderbolt produced on a Stratasys J750 multi-material, full-color 3D Printer, photo courtesy of FFHK“Now, participants can be as imaginable [...]

Funciones últimamente usadas

http://cimquesttv.wistia.com/medias/2dyq02xc1u?embedType=async&videoFoam=true&videoWidth=640 La capacidad incrementada del sistema de recordar funciones últimamente usadas les ayudará a reducir movimientos innecesarios del ratón a medida que trabajan.

Nueva y Mejorada Interfaz de Cinta Edit

http://cimquesttv.wistia.com/medias/d5c7555rwy?embedType=async&videoFoam=true&videoWidth=640