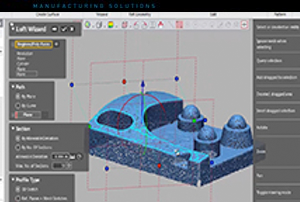

Cimquest Answers Your 3D Scanning & Reverse Engineering Needs

We now have a wide spectrum of scanning, reverse engineering, and metrology services that we provide in-house. Whether you need to capture organic shapes or generate highly accurate scans of mechanical parts, our experts will apply first-rate technologies to get your jobs done. Through our services we can: Capture high resolution 3D scans with state-of-the-art scanners. Modify and repair point clouds from scanned data. Carry out solid and surface modeling on parts. Measure internal and external features of injection molded plastic parts. Compare CAD files to scan or point clouds for precise inspection and much more. To learn more about these services, please click the button below. More Info

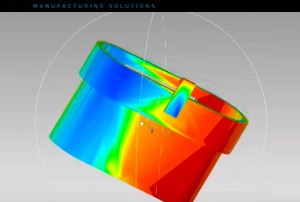

Introducing Rapid Inspection, LLC

The assets of CGI, Inc. have been acquired by Rapid Inspection, LLC, a subsidiary of Cimquest Inc. based in Branchburg NJ with branch offices in Massachusetts and Pennsylvania. Rapid Inspection, LLC will concentrate on using the unique 3D scanning technology (3D IRIS) acquired from CGI to supply highly accurate internal and external scans to aid injection molders with faster tooling qualification and robust processes. 3D IRIS offers a diverse range of inspection services, including scans for: 100 percent First Article report As9102 Format (injection molded and 3D printed parts) Comparison part to 3D CAD model (3D colormap files) Part to part comparison (3D colormap files) Cavity to cavity • prototype to production mold • mold to mold 3D printed part to injection molded part Injection mold process DOE samples More Info

Stratasys Custom Materials Development

Custom Materials Development Enables Printed Parts for Aerospace that are Electrostatic Discharge Safe. By Scott Sevcik, Director, Aerospace & Defense Business Development, Stratasys Once a satellite is launched, there is no way to fix something that breaks. That drives the need for incredibly high reliability in an extreme environment. Temperatures can range from -150°C to +150°C within an hour, there is no air flow, and electrostatic charges can build up very quickly. An electrostatic discharge can damage or destroy the sensitive electronics required to operate the satellite, leaving a very expensive piece of space trash behind. All of these environmental extremes need to be planned for and addressed in the design of spacecraft equipment. The traditional advantages of additive manufacturing for aerospace – namely, reduced weight and increased design freedom – have led spacecraft and launch vehicle companies to ask Stratasys for help in addressing these challenging environments with 3D printing materials that can meet the extreme temperatures of space without risking electrostatic discharge. This avionics box, 3D printed with Stratasys ESD PEKK material, can dissipate electrical charge buildup without relying on post-processing steps to prepare the production part. To meet the growing demand for material solutions in high requirements industries, [...]

Consumer Product Innovations Driven by Stratasys

The legendary Consumer Electronics Show (CES) has served as the proving ground for innovators and breakthrough technologies for more than 40 years. This year, CES hosted over 3,600 companies across 2.4 million square feet in Las Vegas. Many of the custom accessories on the Ladybird were prototyped and tested with 3D printed parts from Stratasys. Upon entering the Stratasys booth, visitors were immersed in a world where top-tier consumer electronics companies delivered their products to market faster and at a lower cost using 3D printing. One display that was a real stand-out was the Ladybird motorcycle from KlockWerks. This custom Triumph Thunderbird was equipped with several durable FDM 3D printed parts to test for form, fit and function. The saddle bags were 3D printed and mounted on the bike as functional prototypes. The windshield was 3D printed and used for testing wind effects before final production. The bike also featured custom rings around the speakers and a phone mount prototype that connects to the handle bars, all 3D printed to test design iterations and fit before final production. “If it wasn’t for Stratasys and their 3D printing technology, this Ladybird motorcycle would not be a reality,” said Brian Klock, president of [...]

Stratasys Expands 3D Printing Adoption through Simplification

One of the obstacles to driving mass adoption of 3D printing has been the complex, cumbersome workflows required to take a design from CAD to 3D printer. To cross the chasm from the early adopters to the mainstream pragmatists, Stratasys has partnered with Adobe to create a new solution – Stratasys Creative Colors Software, powered by the Adobe 3D Color Print Engine. Stratasys Creative Colors Software introduces a new, simplified design-to-3D print workflow, greater ease of use, and expanded color spectrum for Connex 3D printers. Stratasys continues to simplify 3D printing and drive adoption with the Objet Connex3 3D Printer series. Typically designers and engineers would need to use at least three different systems to create multi-material, multi-color 3D printed models. Not so with the Connex3, armed with Stratasys Creative Colors Software, powered by the Adobe 3D Color Print Engine. It fuses multiple systems into one to produce realistic parts with vibrant, gradient colors, patterns and color textures, plus diverse material properties including over-molding. No painting, assembly, etc., required while capital expenses and delivery times are reduced. Remember that the Connex3 platform is open and extensible, which enables Stratasys to constantly enhance it with new functionalities for added customer value. Stratasys is now [...]

Cimquest Awarded Top Reseller Award from Stratasys, Inc.

Cimquest has been awarded the #1 North American Reseller Award for 2015 in both Customer Satisfaction and Material Knowledge Transfer for the Stratasys product line of 3D Printers. Stratasys has been at the forefront of 3D printing innovation for more than 25 years, fueling the next generation of innovation through their work in aerospace, automotive and education. Stratasys is trusted worldwide by leading manufacturers and groundbreaking designers and Cimquest couldn’t be prouder to win this award. Cimquest’s CEO Rob Hassold spoke about receiving this award: “Cimquest is very proud of this award, we pride ourselves on being a customer-centric company and are continually striving to train our staff in product and material knowledge. We strive to help our customers’ select the appropriate tools for their needs, efficiently utilize those applications, and remain current with emerging technologies. It is our mission to ensure that our customers yield the best possible results and return on their investments. There are so many choices in the world of manufacturing and we know it can quickly become overwhelming. We always want to be a trusted resource for the manufacturing community.” For more information on our Stratasys line of products, please click on the button below. More Info [...]