Desktop Metal™ exists to make metal and carbon fiber 3D printing accessible to all engineers, designers, and manufacturers.

Materials Engineered to Perform

Desktop Metal provides a wide range of both metal and composite 3D printing materials to produce parts for every application.

Metal

The metallurgy behind the Studio System™, Shop System™, and Production System™ is built upon the material science and established powder supply chain of the metal injection molding (MIM) industry. When combined with our in-house expertise in material processing, binder compounds, and metal 3D printing, the result is high-quality metal parts with affordable material costs.

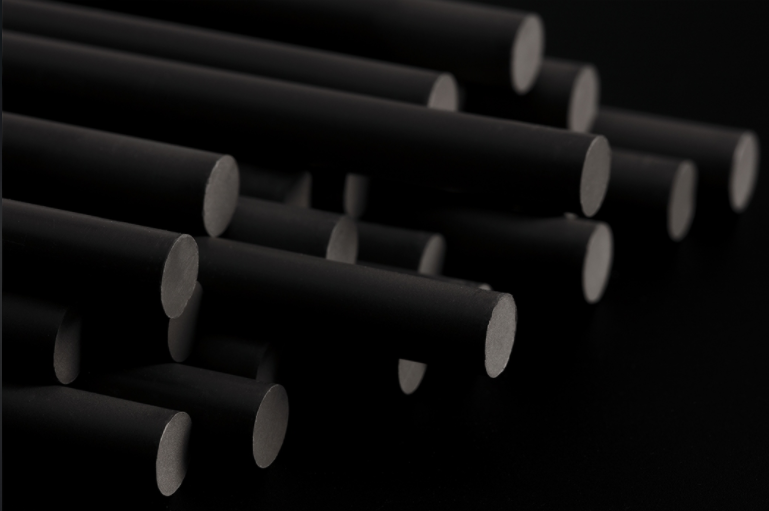

Composite

Micro Automated Fiber Placement (µAFP) – a miniaturized version of the systems used to create aerospace components – enables Fiber™ to reinforce critical paths with continuous carbon fiber or fiberglass. Combined with industry-tested composites like PEEK, PEKK and PA6 nylon, the result is parts that are as strong as steel yet as light as aluminum.