See Live 3D Printing and Scanning at EASTEC 2025!

Join Cimquest at Booth #5433 during EASTEC 2025 and experience live demonstrations of the latest in 3D printing and 3D scanning technology! From HP Multi Jet Fusion to Formlabs SLA, UltiMaker FDM, and Shining 3D scanning solutions — discover how additive manufacturing can transform your production.

See live 3D printing

Explore metal 3D printing and scanning solutions

Talk with Cimquest experts

Event Hours

Tuesday, May 13 – 9 a.m. – 5 p.m.

Wednesday, May 14 – 9 a.m. – 5 p.m.

Thursday, May 15 – 9 a.m. – 4 p.m.

Join Us – On Us!

🎟️ Register for FREE using our Promotional code 11059085.

Venue Information

Eastern States Exposition

1305 Memorial Ave.

West Springfield, Massachusetts

Purchase Parking

Explore a Full Range of 3D Printing Technologies – LIVE at Our Booth

Cimquest will be running live demos on a suite of powerful 3D printers spanning multiple technologies—including FDM, SLA, and SLS. Whether you’re looking for prototyping agility or production-grade performance, we’ll help you find the perfect solution.

Xact Metal XM200G – High-Performance Metal Printing

- Technology: Powder Bed Fusion (Laser-Based)

- Why It Stands Out: Combines precision and affordability, bringing metal 3D printing to small-to-mid-sized businesses.

- Use Cases: Tooling inserts, medical components, aerospace brackets (Static display only)

- Perfect For: Shops exploring metal AM without the high barrier to entry

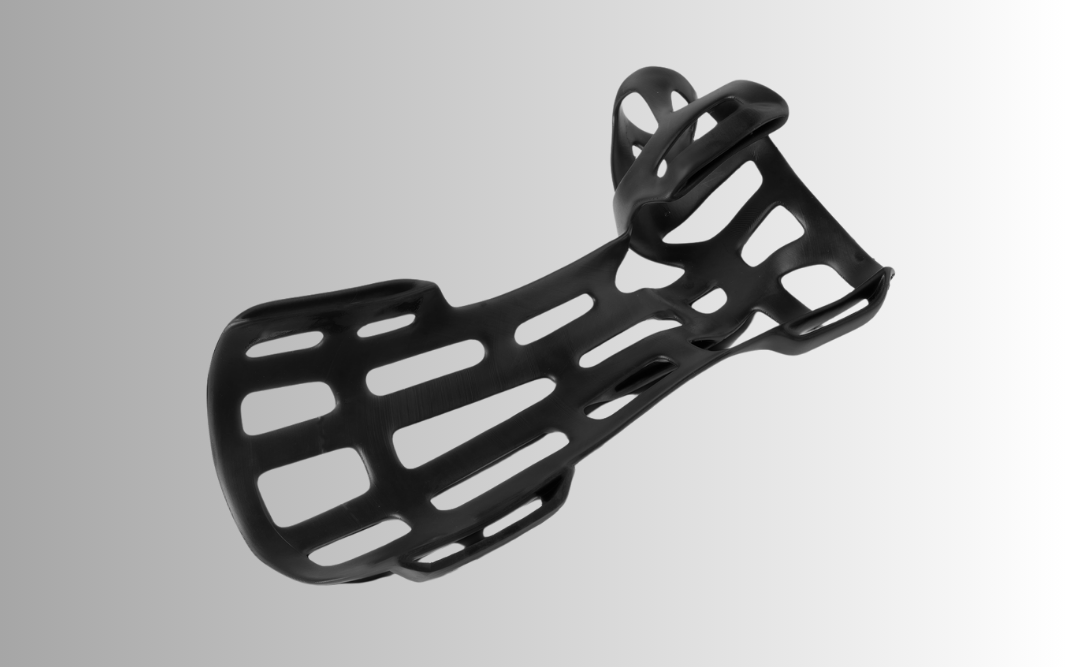

HP Multi Jet Fusion (MJF) – Production-Ready Plastic Parts

- Technology: HP’s proprietary Multi Jet Fusion

- Why It Stands Out: MJF offers unmatched part strength, dimensional accuracy, and fast batch production—ideal for short-run manufacturing or end-use plastic parts.

- Use Cases: Housings, brackets, enclosures, and functional prototypes

- Perfect For: Companies scaling up additive for production parts with tight tolerances

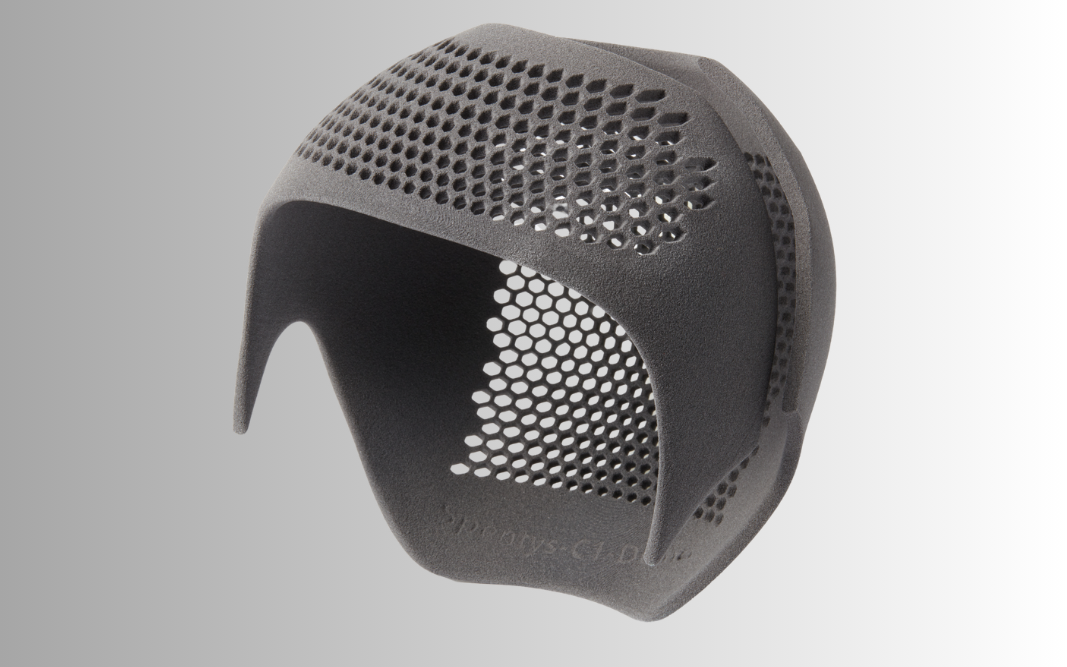

Formlabs Fuse 1+ – Industrial SLS, Made Accessible

- Technology: Selective Laser Sintering (SLS)

- Why it Stands Out: Compact, affordable SLS with superior mechanical properties and no need for support structures.

- Use Cases: Complex geometries, snap-fits, housings, and end-use parts

- Perfect For: Functional prototyping, bridge production, and engineers designing intricate parts

- Live Printing at Eastec 2025

Formlabs Form 4L – Lightning-Fast SLA with Massive Build Volume

- Technology: Stereolithography (SLA)

- Why It Stands Out: The Form 4L combines ultra-fine resolution with a large build area, producing smooth surface finishes and intricate details at speeds that rival FDM.

- Use Cases: Dental models, prototypes, jigs, and fixtures

- Perfect For: Designers and engineers needing high-detail, client-ready parts

- Live Printing at Eastec 2025

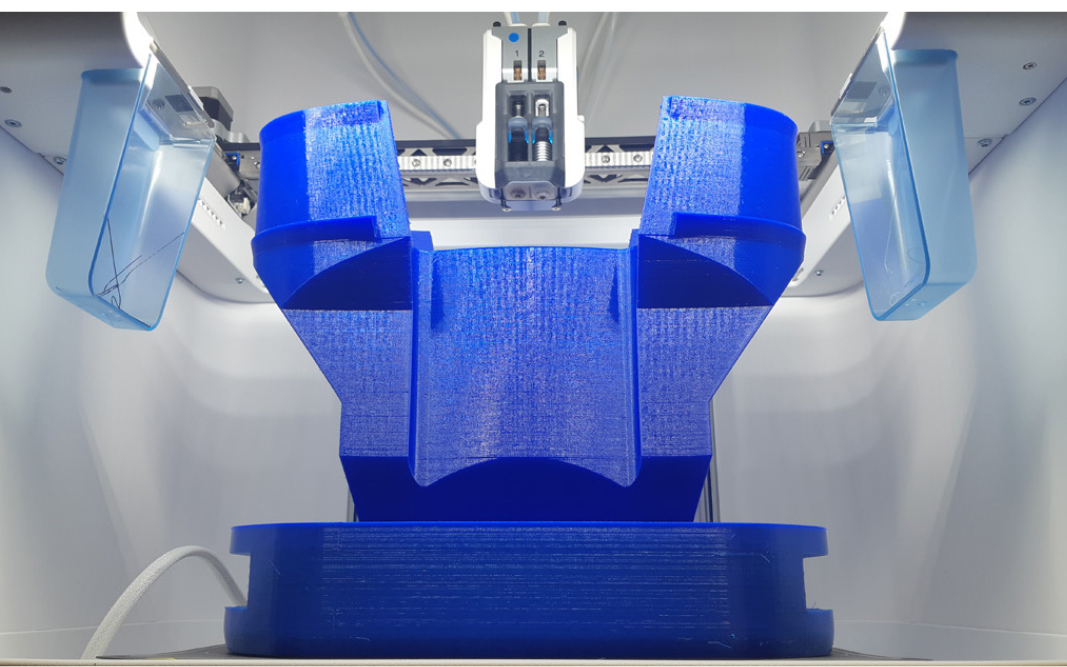

UltiMaker S8 – Reliable Dual-Extrusion FDM

- Technology: Fused Filament Fabrication (FDM)

- Why It Stands Out: Precision dual extrusion with high uptime and material versatility. Great for everyday prototyping and development.

- Use Cases: Concept models, fixtures, and multi-material assemblies

- Perfect For: Product designers, educators, and manufacturing engineers

- Live Printing at Eastec 2025

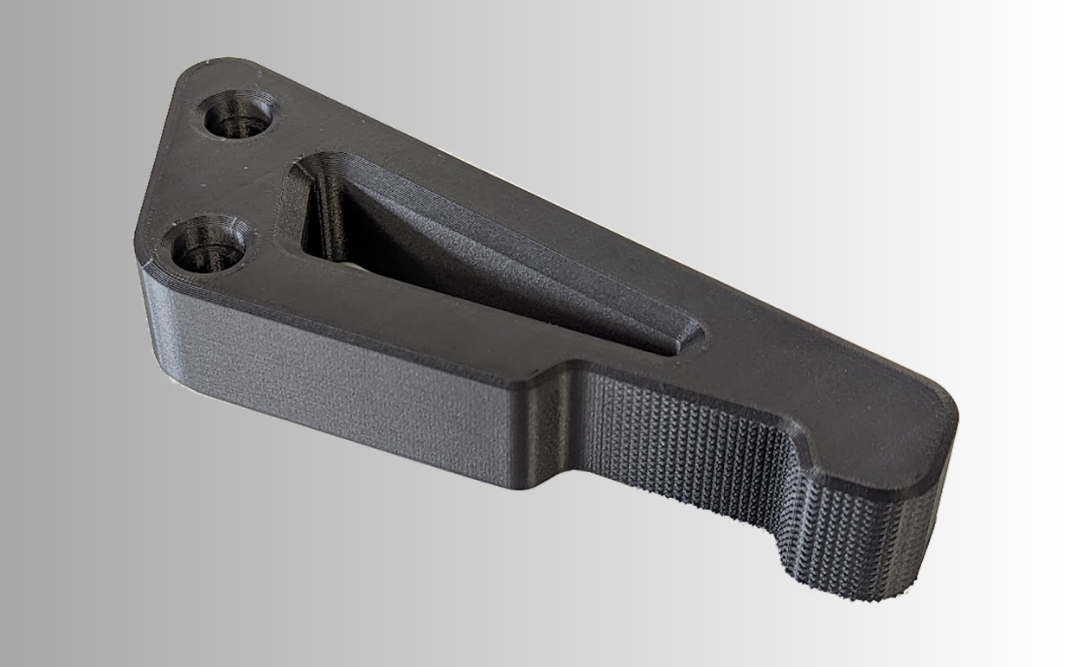

UltiMaker Method XL – Industrial Performance in a Desktop Form

- Technology: FDM with a Heated Chamber

- Why It Stands Out: Built for precision and consistency with engineering-grade materials like ABS-R and carbon fiber composites.

- Use Cases: High-strength functional parts, end-use components

- Perfect For: Manufacturers needing high accuracy and material strength without investing in a full industrial system

- Live Printing at Eastec 2025

Professional Surface Finishing with AMT PostPro SFX

Experience automated vapor smoothing with the AMT PostPro SFX—a cutting-edge solution for finishing 3D printed parts with injection-molded quality.

- Smooths complex geometries and internal cavities

- Improves mechanical properties and seals surfaces

- Compatible with SLS, and MJF parts, including Nylon and TPU

See how PostPro SFX transforms rough, powder-based parts into high-performance, end-use components—all in a compact, easy-to-use system ideal for low-volume production environments. This finishing technology integrates seamlessly into your additive workflow, helping you reduce post-processing time and improve part quality without manual labor.

High-Precision 3D Scanning & Scan-to-CAD Software

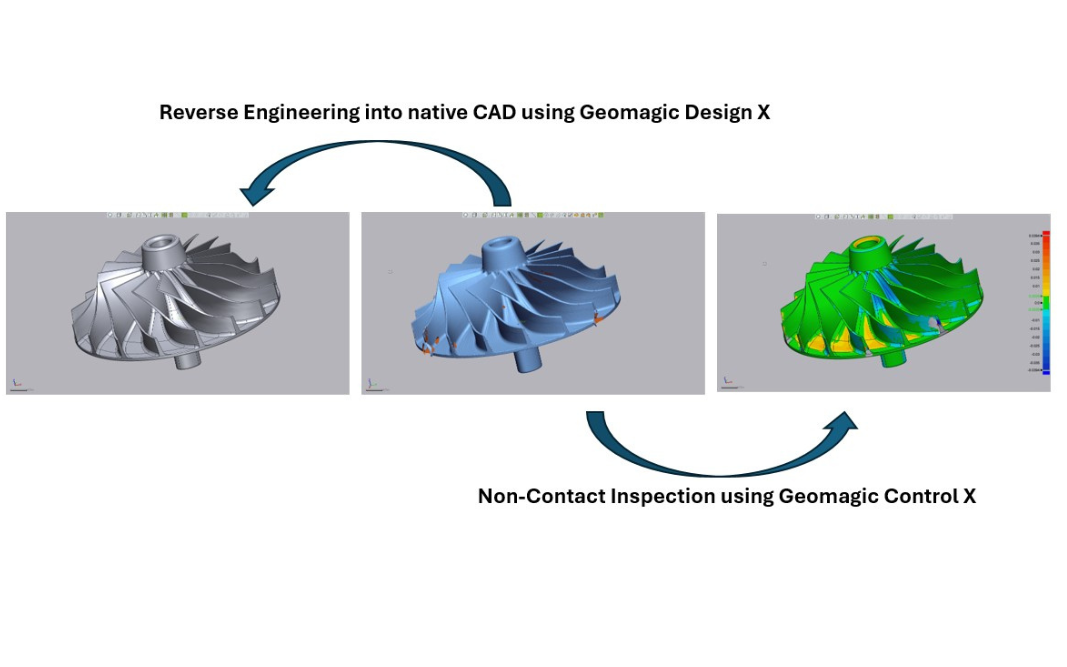

Explore the complete 3D scanning workflow with Shining 3D scanners and Geomagic software—a powerful combination for reverse engineering and inspection.

- Reverse engineering legacy parts

- Performing accurate first-article inspections

- Digitizing tools, fixtures, and prototypes for CAD reconstruction or analysis

We’ll demonstrate how scan data captured with Shining 3D hardware flows directly into Geomagic software, giving you a streamlined, end-to-end solution that fits seamlessly into modern manufacturing environments.

🎟️ Register for Free with Cimquest’s Promo Link

Avoid the registration fee and get full access to EASTEC with our exclusive free pass: