ETEC offers a variety of 3D printing systems with the ability to mass-produce polymer parts with the speed and quality needed for demanding end-use applications. ETEC printers deliver parts with exceptional accuracy, superior part properties, fine feature detail, and smooth surface finish at a scale and cost that is competitive with traditional manufacturing techniques like injection molding.

END USE PARTS AT PRODUCTION SCALE

Printers

From desktop production of small parts to 24/7, lights-out manufacturing to large, production-grade printers, ETEC solutions address a wide range of production scales.

Materials

With more than 190 materials, from hard plastics to high-performance elastomers to high-temperature materials, ETEC’s material portfolio can address a huge range of applications.

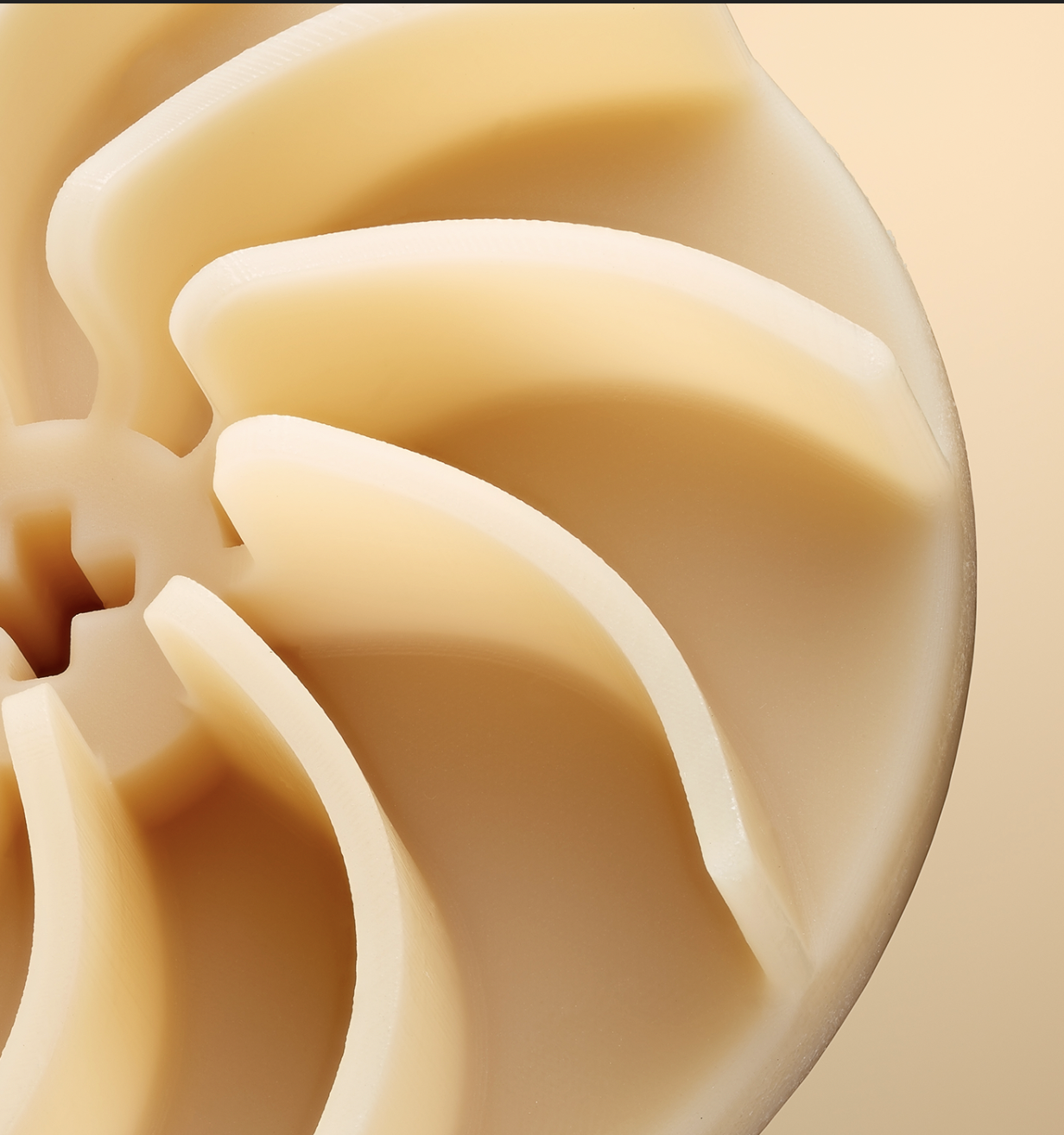

High Accuracy + Feature Detail

ETEC’s advanced DLP printing process delivers best-in-class part accuracy and feature detail down to the micron level.

Smooth Surface Finish

ETEC DLP parts deliver best-in-class surface finish with less than 1um Ra. This exceptional smoothness is critical to compete with plastic injection molding and is the result of more than 10 years of research & development devoted to perfecting the DLP process.

High Throughput

ETEC printers enable throughput [up to 100x legacy FFF 3D printing processes] to deliver parts at volumes and costs competitive with traditional manufacturing techniques like injection molding.

Superior Part Properties

ETEC combines advanced hardware features such as high-powered projectors and custom-designed optics with materials that leverage long-chain chemistry to deliver truly isotropic material properties critical for end-use applications.

High-performance Materials

With a wide array of materials, including both proprietary and third-party qualified resins, ETEC materials deliver mechanical properties required for for end-use parts across a range of industries and applications.

Easy To Use

ETEC solutions are designed for ease of use from the ground up, with intuitive software that simplifies the process of setting up and starting a print and the ability to switch between materials in just minutes, users can produce end-use parts tailored to their application with ease.