3D print functional steel parts on your Ultimaker

Ultimaker and BASF Forward AM are proud to announce that the Metal Expansion Kit is now available from our network of resellers – meaning it is now possible to print functional steel parts on your Ultimaker S5, at a fraction of the cost of other metal production methods.

At the Ultimaker Showcase event back in April, we unveiled two new solutions that together deliver a breakthrough for 3D printer users. First came Ultimaker Cura 5 offering enhanced detail and print speeds. Now, the Ultimaker Metal Expansion Kit unlocks massive possibilities for Ultimaker customers.

You can now take advantage of a new range of metal 3D printing applications by upgrading the Ultimaker S5 with the Metal Expansion Kit. Its seamless workflow makes creating stainless steel parts easier, more efficient, and affordable. From small series of small tools to auxiliary components.

What’s included?

You may be wondering how an expansion kit allows an existing printer designed for thermoplastic filaments to reliably print metal parts.

There are two key elements. First, the kit includes Ultimaker Print Cores – including a new Ultimaker Print Core DD¹ – with nozzles specially optimized for printing metal and ceramic support materials.

The second ingredient is a workflow developed in deep collaboration with BASF Forward AM. BASF Forward AM filaments and post-processing services are seamlessly integrated into the Ultimaker workflow, so everything’s taken care of – not to mention thoroughly tested and designed for reliable, repeatable printing.

With the kit, you also get access to the latest Ultimaker software optimized for your metal filaments, easy access to the BASF Forward AM order management portal, and extensive e-learning modules developed by metal FFF experts.

Let’s take a look at what’s included:

- BASF Forward AM Ultrafuse® 17-4 PH filament (1 kg)

- BASF Forward AM Ultrafuse® Support Layer filament (300 g)²

- Packaging for green parts and a voucher toward post-processing

- Ultimaker Print Core CC 0.4

- Ultimaker Print Core DD 0.4¹

- Magigoo Pro Metal (50 ml) adhesive

- Free Ultimaker Cura software with optimized metal part slicing features

- Access to exclusive metal FFF e-learning content on Ultimaker Academy

Watch this video to learn more about how the Ultimaker Metal Expansion Kit works.

Metal parts. Up to 90% cheaper

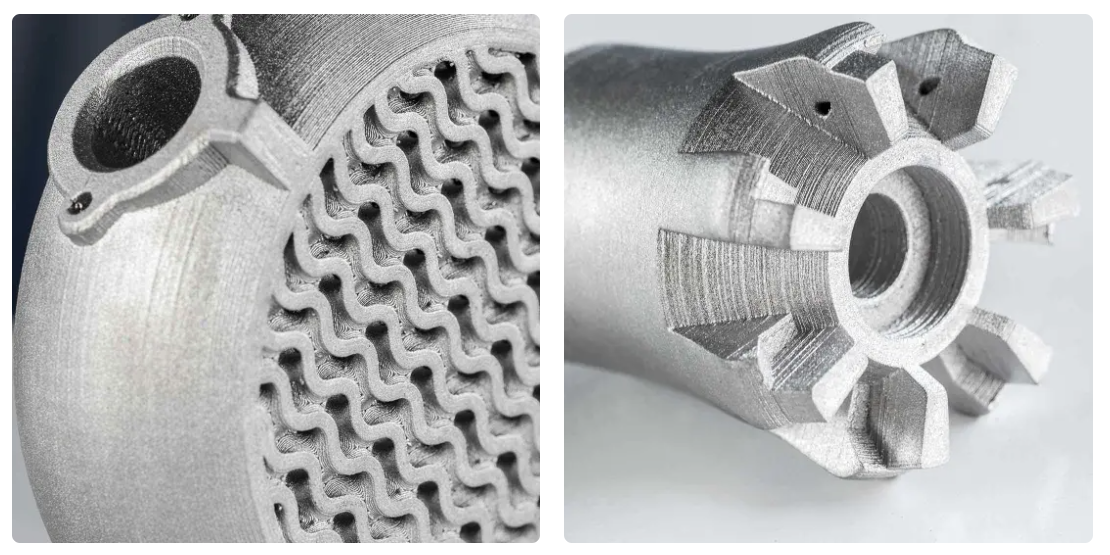

The Ultimaker Metal Expansion Kit combines 17-4 PH stainless steel with a metal-optimized support material². This offers the freedom to create high-strength parts with complex geometries.

BASF Forward AM Ultrafuse® 17-4 PH is an ideal stainless steel for high-strength and stiff parts. It is also capable of withstanding the harshest operating conditions thanks to its excellent corrosion and heat resistance. These properties are achieved through a proven catalytic debinding and sintering process used for traditional metal injection molding.

But reliable metal 3D printing doesn’t have to be expensive. Compared to CNC and other additive methods, you can achieve up to 90% cost-savings. And because the Ultimaker 3D printers fit on your desk or worktop, this solution is easy to adopt and scale based on your need for small series of metal tools and auxiliary components.

Firat Hizal, Head of Metal Systems at BASF Forward AM, said about the launch:

“This unique all-in-one bundle by Ultimaker unlocks metal 3D printing on open desktop platforms like the Ultimaker S5, making MFFF more accessible and affordable. With all the necessary components and accessories in the kit, it facilitates for users switching between printing plastics and metal parts back to back, and helps them throughout the process from A to Z. We are happy to complement this kit with our Ultrafuse® filaments and to offer a simplified post-processing step at a competitive price through our debinding and sintering partners located in different regions”.

Plastic or metal? You decide

Being able to 3D print either plastic or metal on the Ultimaker S5 opens up a wider range of potential applications, making your 3D printer even more versatile.

Metal 3D printing with Ultimaker requires no hardware modifications. Simply swap the print cores, load the material (which is automatically recognized thanks to an NFC chip in the spool), and start your print. The result is a “green” part ready for debinding and sintering.

Leave A Comment