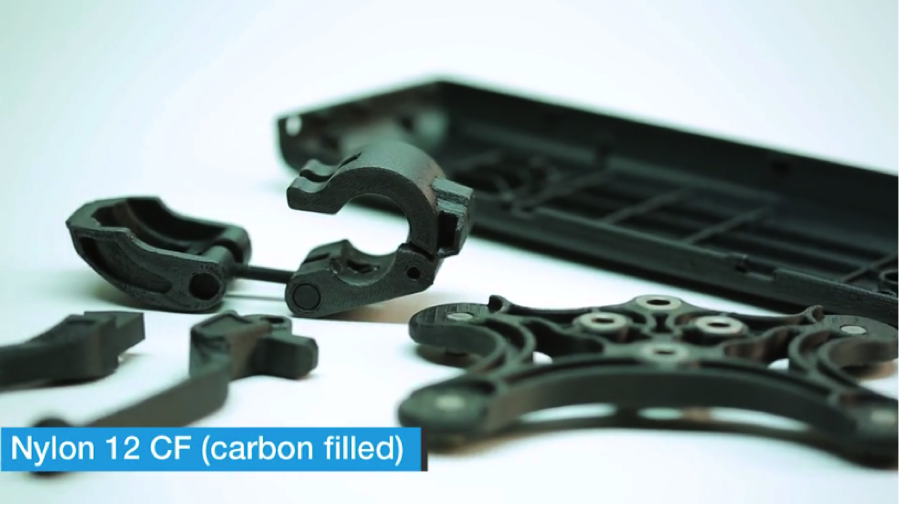

There is a new game-changing thermoplastic material for the Stratasys FDM family called Nylon 12CF. The CF is an abbreviation for carbon filled. In this material, chopped carbon fibers are added to a proven FDM Nylon 12 polymer blend resulting in one of the strongest thermoplastics in the FDM material portfolio.

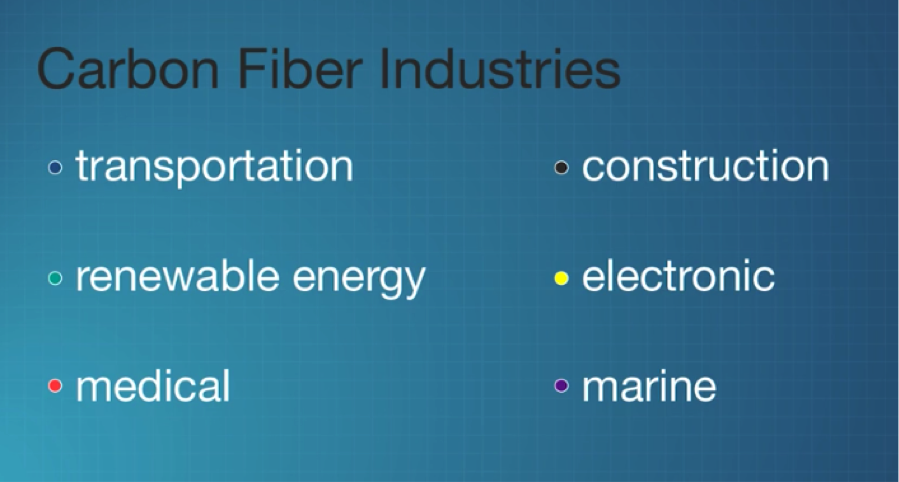

Commercial production of carbon fiber began in the early 1960’s, resulting from requirements for lighter weight parts and alternatives to metal. Its low thermal expansion, heat resistance, and chemical stability made it a viable solution for aerospace parts as it offered ten-times the strength of steel at one-quarter of the weight. Over the years, the use of carbon fiber branched out into many other industries.

It is extremely popular in performance racing, where it is used to create composites that are light and have exceptional fatigue characteristics.

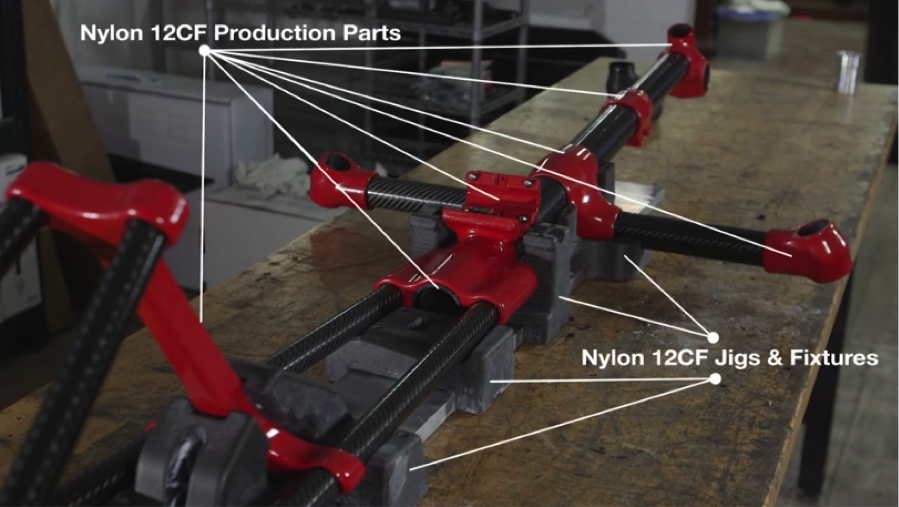

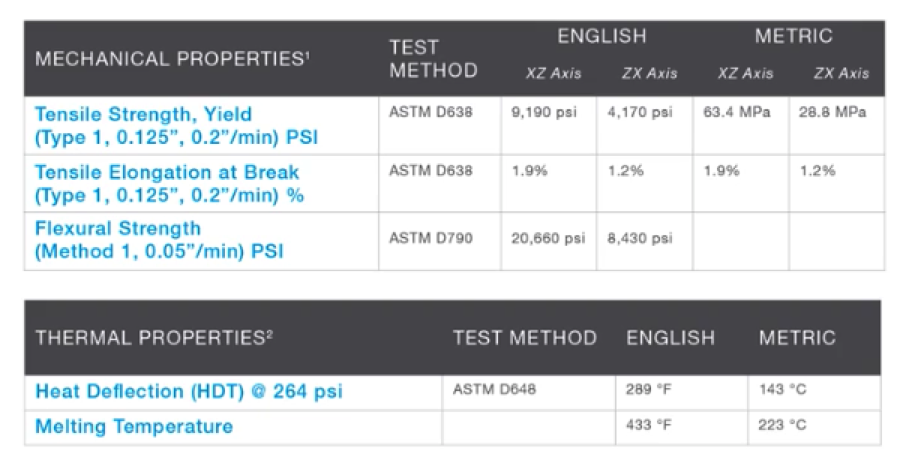

For 3D printing, Nylon 12 CF provides the highest flexural strength and highest stiffness-to-weight ratio of any FDM material currently produced and a tensile strength on par with other high-performance FDM materials. Appropriate uses include strong but lightweight tooling, functional prototypes and end-use parts in aerospace, automotive, recreational and industrial applications.

In tooling applications, thermoplastics might have the strength but lack the rigidity that is required. Therefore, the natural tendency is to design with aluminum or some other metal alloy. However, this is where composite materials come into play. Adding a reinforcement to the base polymer drastically changes the mechanical properties making it possible to replace some metal parts. For prototyping, Nylon12CF works best in functional testing, especially in highly customized parts that can be cost-prohibitive to machine. With SR-110 soluble support material; advanced geometries that are difficult to shape in aluminum or in conventional carbon-fiber layups, can be designed without major restrictions.

Nylon 12CF is currently available on the Fortus 450 production 3D printer. Combined with the powerful Insight software; toolpaths and printing parameters can be modified to print parts faster, with superior stiffness-to-weight performance and better repeatability that any other 3D printing technology.

As you can see, with Nylon 12CF provides the ability to go from design to in-use part thus allowing engineers and designers to spend more time perfecting their designs. For more information on our complete line of Stratasys 3D printers, please click the button below.

[button link=”https://cimquest-inc.com/products/stratasys-3d-printing-solutions/” color=”default” size=”” stretch=”” type=”” shape=”” target=”_self” title=”” gradient_colors=”|” gradient_hover_colors=”|” accent_color=”” accent_hover_color=”” bevel_color=”” border_width=”1px” icon=”” icon_divider=”yes” icon_position=”left” modal=”” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” alignment=”left” class=”” id=””]More Info[/button]

Leave A Comment