Most CMM’s will ship with a language-based CMM programming software package that is powerful but very time-consuming to learn and challenging to master. It is therefore very common for job shops and manufacturing facilities to have just a single CMM programmer who has gone through the painstaking efforts of becoming proficient with the software. But what happens when that person goes on vacation, is out sick, or leaves the company? Many shops own very expensive CMM’s that are either very underutilized due to the challenges associated with CMM programming or worse, are sitting completely idle.

Introducing the Universal CMM (UCMM) from Verisurf Corporation

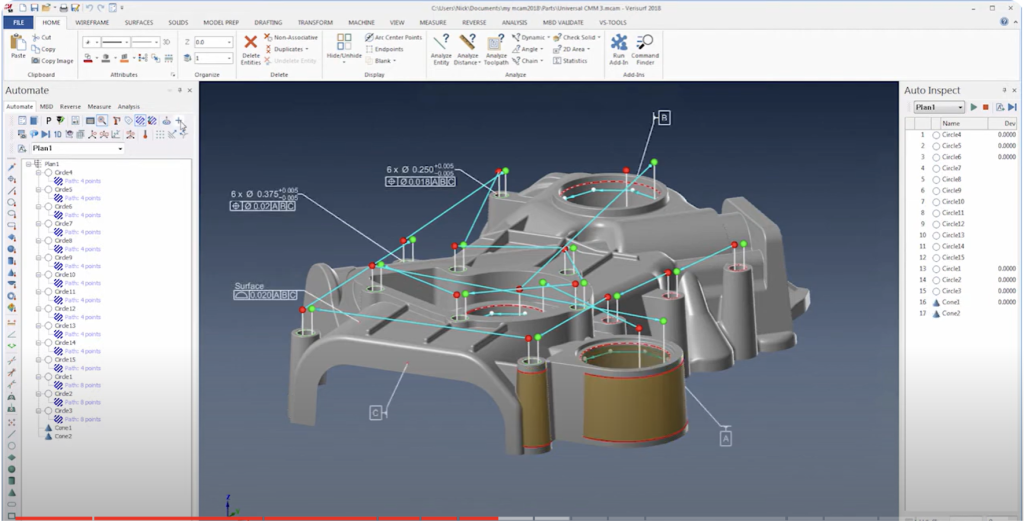

The UCMM enables any CMM to be programmed and run from within the Mastercam Design environment, thereby opening the doors to convert any Mastercam CNC Programmer into a CMM programmer in no time at all!

All of the CMM’s functionality is fully supported through the UCMM, including; probe calibrations, multiple part alignment techniques, Indexing heads, probe changers, joysticks, tactile scanning, and more.

The UCMM is also a ‘codeless’ CMM programming system. Therefore all programming and execution of a CMM program takes place from within the graphical Mastercam environment. Post Processors, as required for CNC programming, are not needed for CMM programming. What is viewed on the graphics screen is exactly what you will see on your CMM!

What is extremely important is the Universal CMM does not disable your existing CMM programming software or hardware in any way. So legacy inspection programs will still be fully functional.

3D Scanning and Reverse Engineering for Mastercam CNC Programming Applications

Much like 3D printers, scanners and scan processing software are becoming much more prevalent in job shops and manufacturing facilities throughout the U.S. Geomagic Design X reverse engineering software has the tools to take the scan of a part or assembly (mesh or point cloud) and use it as a template to recreate the virtual part from a scan. Planes, sketches with constraints, dimensions, features, etc. can all be created and resultant models appear as if they were built, from scratch, within the supported native CAD system. These models will be 100% editable in CAD.

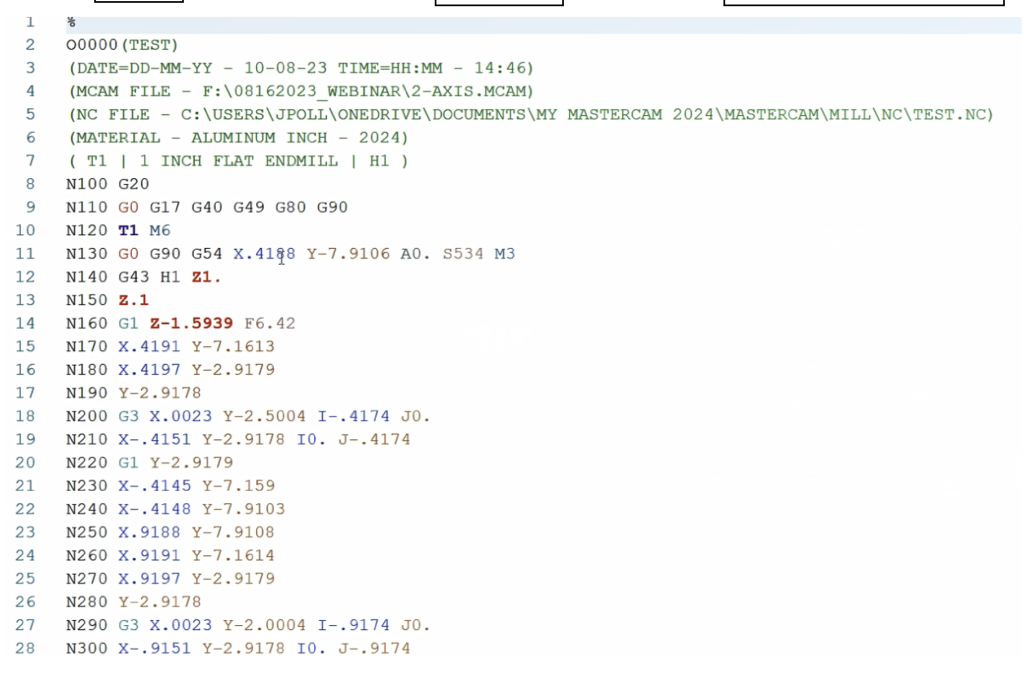

But for CNC Programming in Mastercam, much of that native CAD data isn’t required. The CNC Programmer simply needs a ‘CAD-based Step file’ that contains machinable features and from that, they can generate Mastercam toolpaths and, most importantly, generate ‘clean’ G-Code files.

Leave A Comment