In the world of golf, precision and innovation go hand in hand. The quest for the perfect putter has led enthusiasts and professionals alike to explore various materials, designs, and technologies. Enter the realm of 3D printing—a groundbreaking technology that is redefining the boundaries of golf equipment. Please join us at one of our upcoming events:

“Cimquest Manufacturing Expo: Teeing Up Innovation” on June 11th at our headquarters, located in Branchburg, NJ, and “Metal Optimization: An In-Depth Look into Xact Metal at Voxel” on July 9th at Voxel’s headquarters in Cincinnati, OH where we will explore 3D printings role in golf’s star; the putter.

We have two exciting giveaways in addition to all the fun goodies you’ll receive at the event: a Yeti Cooler filled with our partners’ swag and a “one of a kind” 3D Printed golf putter!

While we are doing golf giveaways and it is golf-themed, you don’t have to love golf to attend! We will have multiple partners there to showcase their technology. In addition to our staff, experts from the following companies will be attending:

- Desktop Metal

- Formlabs presenting the new Form 4

- UltiMaker

- HP

- Xact Metal

These pros will be at the various stations throughout the expo and will be able to answer any questions you might have!

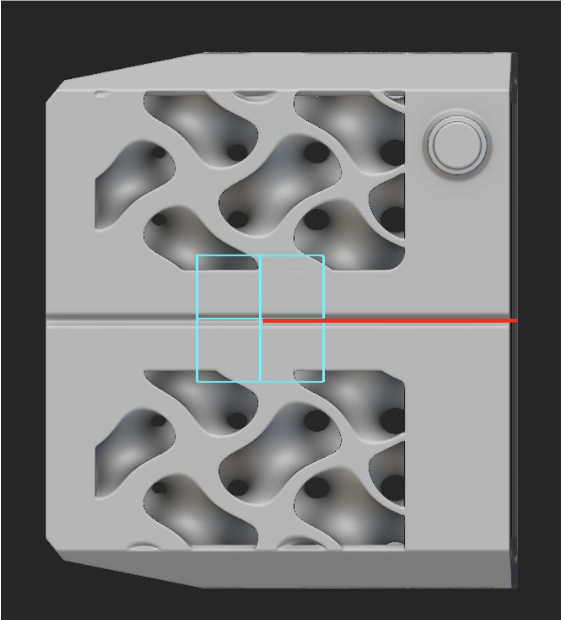

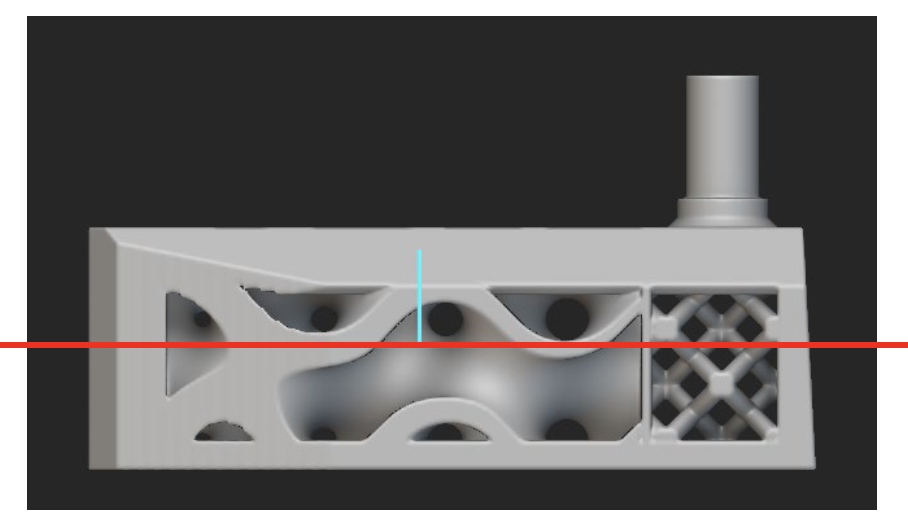

Voxel is a software and engineering company developing technology that enables design engineers to create high-performing, complex components manufactured with additive manufacturing. With the help of AI this software can predict performance of a variety of performance characteristics based on the designer’s performance goals and in this case, adjusting a golf putter. The first optimization that the modern-day golf putter went through was adjusting the center of gravity placement distance from the club face. Mallet putters seek to place the CG (center of gravity) as far back from the club face, as this increases the “sweet spot.” Voxel’s varying thickness geometry allows us to push the CG as far back as possible without compromising the structural strength of the putter.

Voxel also adjusted the center of gravity height by adjusting the varying thickness geometry. While most clubs seek to place the CG as far below the contact point as possible to increase launch angle, putters seek to do the exact opposite to prevent “popping” the ball up. The varying thickness geometry has allowed Voxel to place the CG far above the equator of the club, causing the club to push the ball down and prevent bouncing.

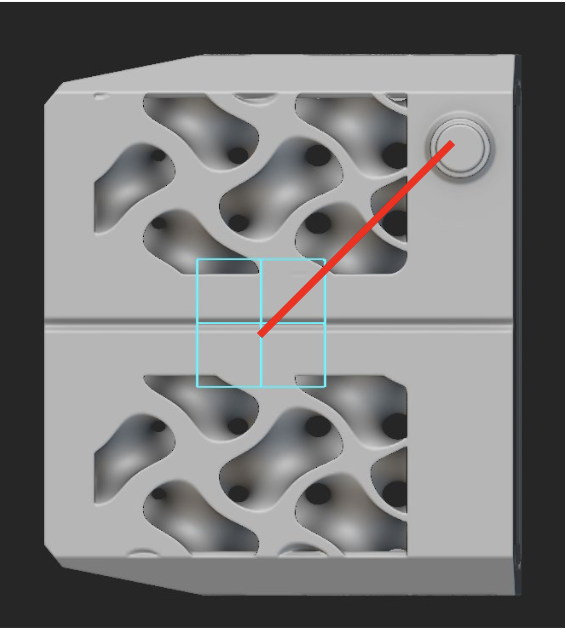

Lastly, in order to create an advanced putter, they attempted to perfect the swing plane. Each golfer has their own unique putting stroke with different swing planes. Each of these swing planes can cause mis-hits, but this can be minimized by offsetting the CG from the shaft of the putter. Since additive does not require tooling infrastructure, as AM can produce parts directly from design files (whether designed by the hand of an engineer or algorithmically) without the need for infrastructure specially designed for each unique part, these clubs can be designed and produced to perfectly suit each golfer, which in this instance was a generalized swing plane, but showcases how AM can enhance the future of golf.

Learn more about the upcoming events by watching the video below.

Located near or in Branchburg, NJ?

Want to see this putter in action and have a chance to win it? Come to our event on June 11th “Cimquest Manufacturing Expo: Teeing Up Innovation” where you’ll have the chance to swing into the future with an array of captivating presentations and interactive experiences with all of the technologies that Cimquest has to offer. Our headquarters boosts almost the entirety of our 3D Printer portfolio in terms of vendor representation. We’ll even have experts from Formlabs, HP, Desktop Metal, Xact Metal and UltiMaker attending so they can answer your questions directly.

Located near or in Cincinnati, OH?

Interested in learning more about Voxel and how they’re changing the game with their XM 200G? Attend our event on July 9th where you’ll get a tour of Voxel, a demonstration with their XM 200G from Xact Metal and a presentation from both Voxel and Xact Metal on how they’re changing the game for AM. Register here: [LINK COMING]

Leave A Comment