Don’t be held back by older technology or traditionally expensive machines.

Xact Metal™ takes the essential specs for metal laser powder-bed fusion (LPBF) and combines them with breakthrough technology to establish a new level of price and performance for additive manufacturing.

Leading Technology

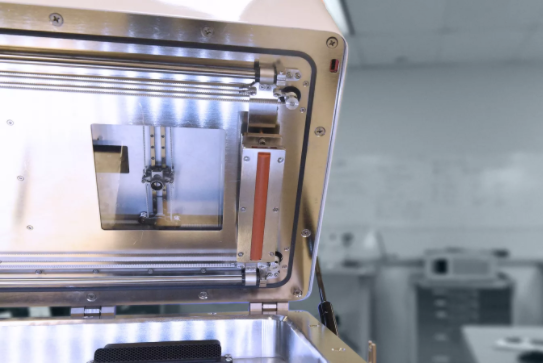

Xact Core™

Making quality metal printing accessible requires innovation. Xact Metal’s printing technology is built on the patent-pending Xact Core, a high-speed gantry system platform that allows light, simple mirrors to move quickly and consistently above the powder bed on an X-Y axis.

- Avoids the use of complex rotating galvanometer mirrors and F-theta lenses

- Maintains a constant laser angle across the whole build plate

- A simplified gas flow over the powder bed due to the smaller build chamber

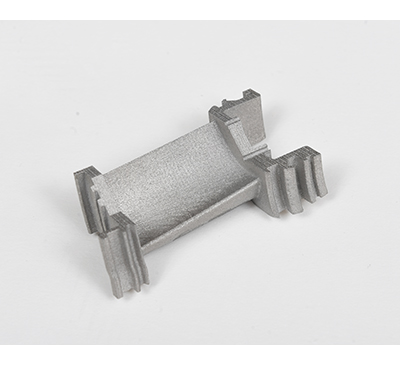

Patent-Pending Recoater

Recoater performance can directly affect the quality of your build. Our patented recoater design offers a variety of benefits.

- Unique “bulb” shape of the recoating element spreads powder like a blade, yet provides compaction similar to a rolling element

- Compliant design allows the recoater to negotiate out-of-plane growth and continue printing

- Mounting the recoater to the machine lid allows the entire recoating mechanism to be removed from the build chamber

- Easy access to the build chamber allows for simple recoater replacement and adjustments

Intuitive Touchscreen User Interface

The modern, interactive graphic user interface (GUI) for the XM200C makes loading files, setting up builds and monitoring the build process quick and easy.

- Home screen displays real-time build monitoring with two cameras

- Chamber setup screen allows customer to optimize print parameters

- Build queue screen provides a description of all builds to be printed

- Monitoring screen shows behavior of important parameters such as bed temperature, chamber temperature and pressure and oxygen percentage