What’s New in Tooling-Free Manufacturing?

What could it mean to your business if you no longer needed to build jigs, fixtures, and molds? It means your engineers could design and produce end-use parts in as little as one day!

If you need to print multiple versions of a part or make unique iterations binding jetting is the answer. By using binder jetting for metal 3D printing you will have the speed and accessibility to design and produce dozens of iterations in as little as a week.

Once part designs are finalized, binder jetting technology makes it easy to go from printing a prototype or low volume bridge runs to produce thousands or even millions of parts. When there is no need for tooling or complex set-ups manufacturers can produce a part on one day and switch to a new part the next day with no delay in production.

What are the Benefits?

3D Printing gives you the freedom to “design-for-additive-manufacturing” and eliminates the time and cost of hard tooling. DfAM provides you with the ability to make lightweight parts without sacrificing strength. And 3D printing also eases the burden on your shop floor. Engineers and designers no longer have to restrict part designs based on machining capabilities. 3D printing is not inhibited by part-complexity. Now, a component that previously involved multiple parts and a final assembly can be done in a single print. It is not uncommon to achieve part-cost savings of 75% or more.

Here are a few examples:

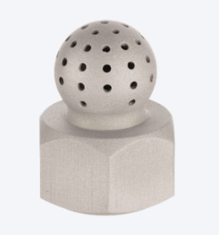

Bulb Nozzle

This part is a custom spray nozzle used in chemical processing. Though normally cast, followed by extensive secondary machining operations, this part needed to be produced in quantities of approximately 300, making it an ideal fit for the Shop System™. By printing the nozzles, the entire order could be produced in less than a week and required just one secondary thread-tapping operation. Depending on the chemical operation, different spray geometries may be required. Since 3D printing eliminates the need for tooling, the nozzle can be changed on demand and printed to conform to each process.

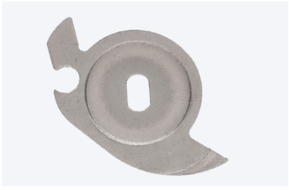

Seat Belt Pulley

This output pulley is an essential component of the retracting mechanism in a car seat belt. This part features an undercut radial groove that, without printing, would require advanced sliders during the press-and-sinter process. Printing this part with the Shop System™ eliminates the huge cost and complexities associated with press and sinter. Depending on the model of the car, different models of this pulley may be needed. By eliminating the need for tooling, 3D printing allows manufacturers to easily switch between designs. One model can be printed overnight and a different design printed the very next day with virtually no delay or setup time.

Leave A Comment