Understanding Mastercam Finish Passes

In the fast-paced world of manufacturing, efficiency is key. Mastercam’s Dynamic toolpath functionality has long been a beacon of innovation, helping machinists reduce cycle times, extend tool life, and lessen wear and tear on their machines.

With the release of Mastercam 2025, this game-changing toolpath motion has received a significant upgrade with the introduction of finish passes. This new feature promises to take your machining operations to the next level. Let’s delve into how this works and the benefits it brings.

The Evolution of Dynamic Toolpaths

Dynamic toolpaths in Mastercam revolutionized machining by employing a continuous, optimized cutting motion. Unlike traditional toolpaths that follow a more segmented approach, Dynamic toolpaths keep the tool engaged with the material more consistently. This approach removes material efficiently but can sometimes leave behind tool marks as the tool re-engages and exits the cut repeatedly.

In scenarios like machining outside walls or complex geometries, these tool marks can be more pronounced. This is where Mastercam 2025’s enhancement comes into play. The new finish passes feature is designed to address these imperfections, offering a more refined and polished end product.

Understanding Finish Passes

With the integration of finish passes into Mastercam 2025, users can now clean up these residual marks with ease. Let’s take a closer look at how this feature works:

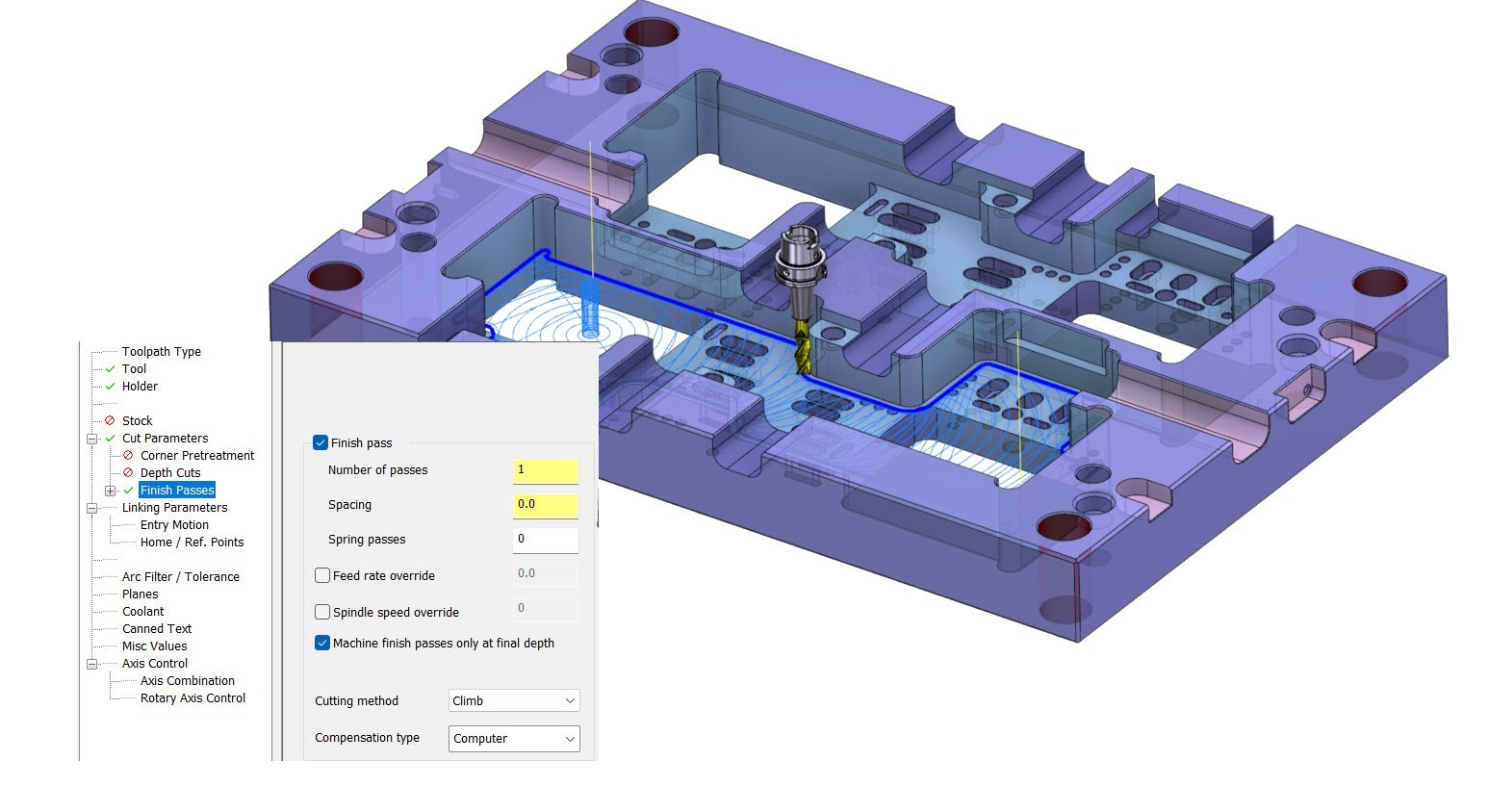

Configuring Finish Passes: When setting up your toolpath, you can now activate finish passes and specify the amount of material to leave for finishing. For instance, setting a 0.5 mm offset for a single finish pass will ensure that the toolpath is adjusted to remove the remaining material with precision.

Finish Pass Settings: Mastercam 2025 offers a variety of finish pass settings to fine-tune your operation. These include options for spring passes, which help in achieving a smoother surface, feedrate overrides, and adjustments for cutting methods and compensation types. These settings allow you to customize the finishing process to meet the specific requirements of your job.

Lead-In and Lead-Out Options: The software also includes an extensive range of lead-in and lead-out settings. These controls dictate how the tool enters and exits the finishing pass, ensuring smooth transitions and reducing the risk of surface imperfections.

Toolpath Recalculation and Safety

Once you enable finish passes and regenerate your toolpath, you’ll notice the addition of extra toolpath motions designed to clean up the walls and remove the residual material. This recalculated toolpath helps in achieving a more refined surface finish, addressing any leftover tool marks.

However, dynamic toolpath motion can sometimes present challenges, especially if the tool does not fully engage with the material due to the radius or shape of the geometry. In such cases, the “Minimize Burial” option ensures that the tool remains in a safe operational environment, mitigating potential risks associated with toolpath engagement.

Benefits and Applications

The addition of finish passes to both 2D Dynamic Mill and Area Mill toolpaths in Mastercam 2025 is more than just a feature upgrade—it’s a significant boost to machining efficiency. By incorporating this functionality, users can save valuable programming time and expedite the transition from toolpath creation to machine operation. The ability to refine toolpaths directly within the software reduces the need for additional post-processing or manual finishing, streamlining the manufacturing process.

To find out more about Finish Passes with Mastercam 2025, contact us today.

Learn more about the Top Mastercam 2025 enhancements.

Leave A Comment