SLA 3D Printing – How Pixel Size Impacts Accuracy, Feature Size, Surface Finish

In the realm of 3D printing, resolution is a frequently discussed but often misunderstood topic. With the rise of various 3D printing technologies and manufacturers, the conversation around resolution has become even more complex. One critical aspect of this discussion is pixel size, especially in the context of Stereolithography (SLA) and Masked Stereolithography (MSLA) 3D printers.

Pixel Size and Its Importance

Pixel size in 3D printing refers to the smallest feature that a printer can reproduce within a single layer. In MSLA 3D printers, which use an LCD screen to selectively mask light and cure liquid resin, the resolution is typically measured by the number of pixels across the screen’s long axis. The general assumption is that smaller pixels result in higher resolution and better print quality. However, the reality is more nuanced.

Beyond Pixel Size: What Really Matters

While pixel size is an important factor, it is not the sole determinant of print quality. Surface finish, dimensional accuracy, and minimum feature size are the tangible outcomes that most users care about. These characteristics are influenced by a combination of factors, including material properties, optical settings, and mechanical consistency.

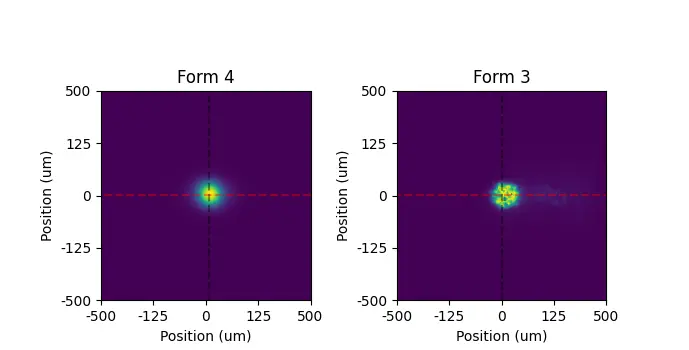

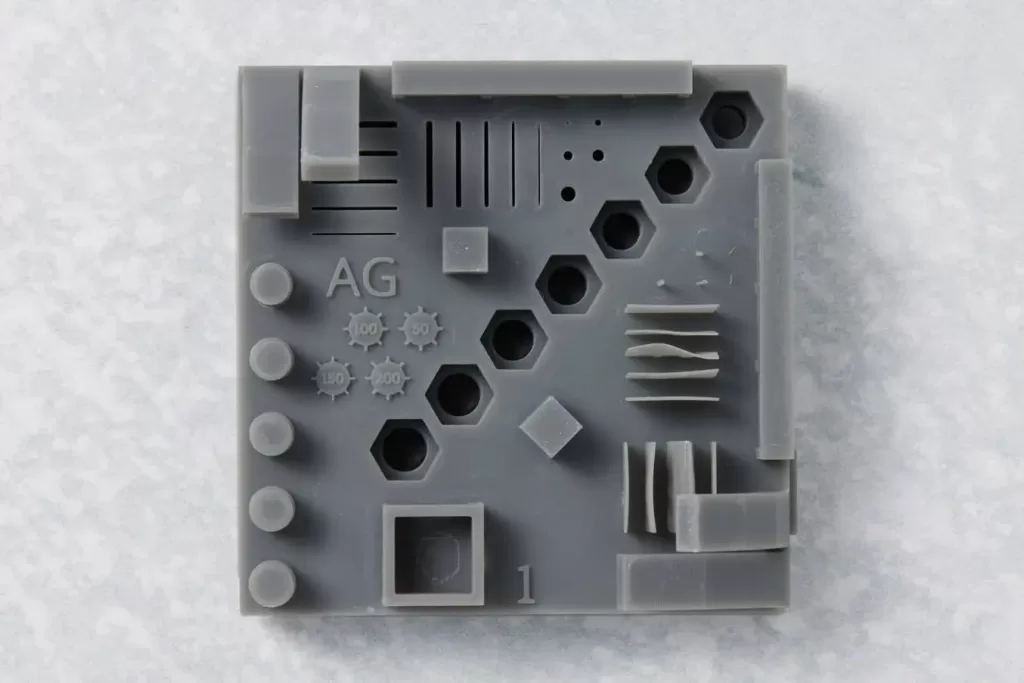

For instance, Formlabs’ Form 4 printer, despite having a larger pixel size compared to some competitors, achieves comparable or even superior results in terms of surface finish, dimensional accuracy, and minimum feature size. This is because the quality, consistency, and uniformity of the light passing through the pixels play a significant role in the final print quality.

Practical Implications for Manufacturers

Understanding the true impact of pixel size can help manufacturers make more informed decisions when selecting a 3D printer. It’s essential to consider the overall design and capabilities of the printer, rather than focusing solely on pixel size. Factors such as print speed, reliability, and component lifetime are also crucial for optimizing production workflows.

Conclusion

Pixel size is an important aspect of SLA and MSLA 3D printing, but it is just one piece of the puzzle. By considering the broader context of printer design and performance, manufacturers can achieve high-quality prints that meet their specific needs. Embracing a holistic approach to 3D printing resolution can lead to better outcomes and more efficient production processes.

Want to learn more about Formlabs and their new Form 4?

Leave A Comment