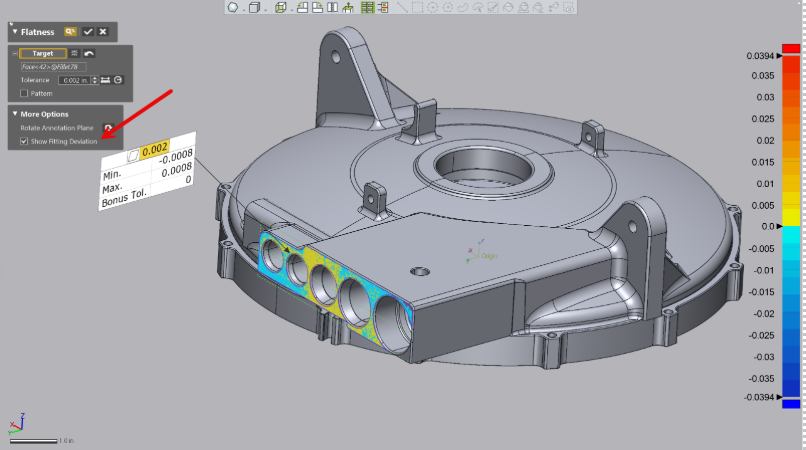

In each of the Control X GD&T commands, users have the ability to color map the Fitting Deviation. So when checking for Flatness, for example, along with being able to show the Min and Max deviations as we do in the examples below, users can actually color map those differences.

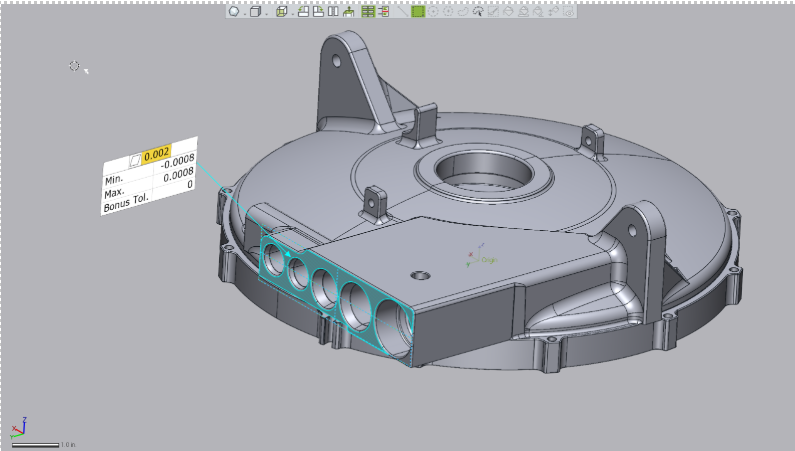

Below we show that the flatness of this face is within its assigned Flatness tolerance of .002” as the Min and Max values are +/-.0008”.

Please contact Joel Pollet (joel.pollet@cimquest-inc.com ) with any questions or to obtain additional information regarding Design X Go.

But by turning on the Color Map Fitting Deviation Switch, we can actually see exactly how that tolerance is distributed, across the face.

We can see that while the planar surface is within its Flatness requirement, we can also see by the yellow color (full or ‘oversize’ condition) that it bulges slightly in the center while being on the ‘low or undersize side’ (blue color) on the ends.

From this information, we can possibly make changes to the CNC toolpath that machines this face or perhaps to the fixturing that holds the part during the machining process to produce an even flatter surface.

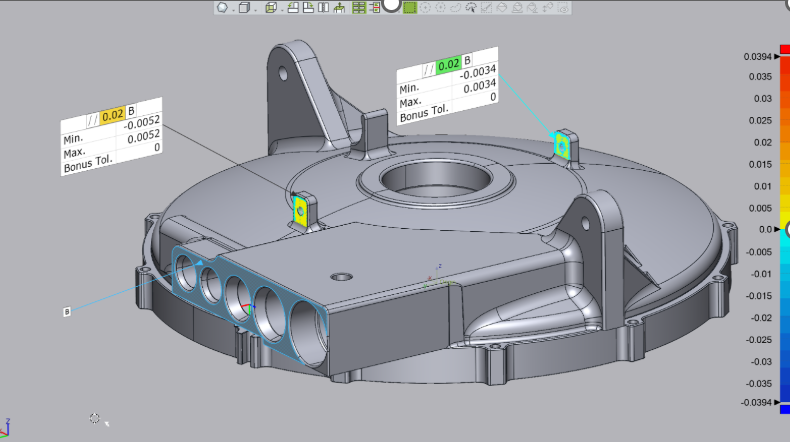

Next we explore color map fitting for checking the Parallelism of two small tab surfaces. For this GD&T Callout, a Datum surface is required. We define the previous surface as Datum B and then check Parallelism with Color Map Deviation Fitting, once again, switched on.

While both surfaces pass the Parallelism testing, we can see that the rear mounting tab surface is machined to remain well within the Parallelism tolerance requirement whereas the front mounting tab surface is closer to being OOT.

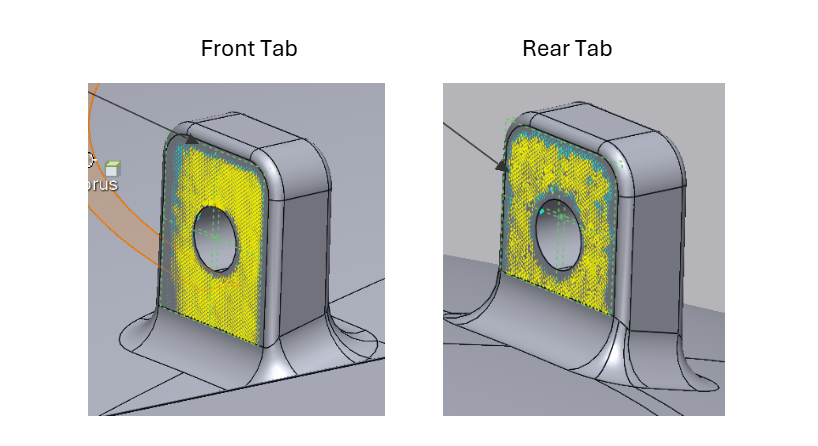

Again, perhaps a comparison of how the two tabs are machined and/or how the part is being held during the machining process could enable the Control X user and the CNC programmer to work together to produce better parts.

The color map distribution shows a more distinct difference on the front tab as compared to the rear tab, where the color map indicates a more parallel condition (i.e. less points that deviate from Parallelism).

Please reach out to Joel Pollet at Cimquest to learn more about Control X and its GD&T capabilities and how CAM users can utilize information extracted by Control X to machine better parts!

Leave A Comment