Fiber™

Fiber™ is the world’s first desktop 3D printer to fabricate high resolution parts with industrial grade continuous fiber composite tape materials used in Automated Fiber Placement (AFP) processes. Based on a new process called Micro AFP (μAFP), users can now print parts with a superior level of strength and stiffness and in a broad range of materials that traditionally required million dollar AFP systems.

During the μAFP process, one Fiber™ printhead deposits a continuous fiber tape along critical load paths to build dense reinforced sections while a second printhead extrudes chopped fiber filament to build a high-resolution exterior shell. The materials used to make the resulting parts are two times stronger than steel at one-fifth the weight (up to 2,500 MPa tensile strength and <1.5 g/cc).

https://cimquesttv.wistia.com/medias/9sbptd22ef?embedType=async&videoFoam=true&videoWidth=640FLEET CONFIGURATIONS

Studio System™

1 printer, 1 debinder, 1 furnace

1x throughput

Studio Fleet (3x)

3 printers, 1 debinder, 1 furnace

3x throughput

Studio Fleet (5x)

5 printers, 2 debinders, 1 furnace

5x throughput

Scale throughput

Studio Fleet makes it easy for manufacturers to scale production for low to mid-volume runs—without the prohibitive costs associated with custom tooling or dedicated production facilities.

COMMON SCENARIOS

Low volume production of custom parts

Aftermarket or replacement parts

Pilot runs prior to mass production

APPLICATION EXAMPLE

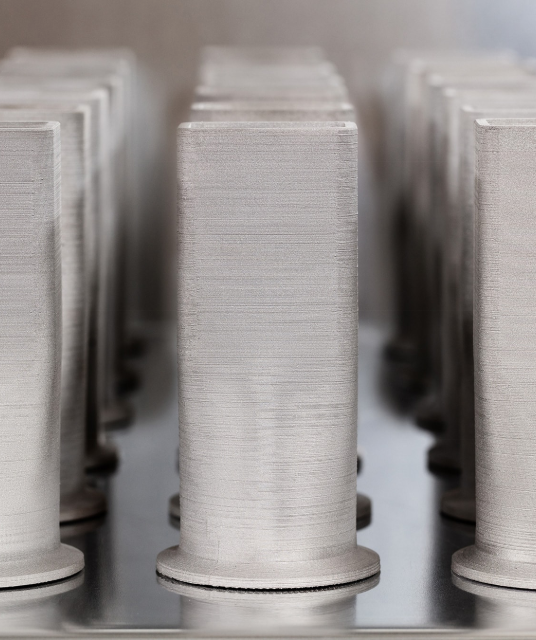

Extruder nozzle

Used to mix two dense ceramic slurries, the nozzle directs flow and defines the shape of extrusion. The application requires a complex loft design and relatively low quantity. Given the strength, stiffness, and thermal resistance requirements, the extruder nozzle must be made of metal.

In-house metal 3D printing is up to four times faster and 90% cheaper than CNC machining or selective laser melting (SLM). And instead of extrusion honing, parts are easily sanded in the green state to achieve critical surface finish on the nozzle interior.