Fiber™

Fiber™ is the world’s first desktop 3D printer to fabricate high resolution parts with industrial grade continuous fiber composite tape materials used in Automated Fiber Placement (AFP) processes. Based on a new process called Micro AFP (μAFP), users can now print parts with a superior level of strength and stiffness and in a broad range of materials that traditionally required million dollar AFP systems.

During the μAFP process, one Fiber™ printhead deposits a continuous fiber tape along critical load paths to build dense reinforced sections while a second printhead extrudes chopped fiber filament to build a high-resolution exterior shell. The materials used to make the resulting parts are two times stronger than steel at one-fifth the weight (up to 2,500 MPa tensile strength and <1.5 g/cc).

https://cimquesttv.wistia.com/medias/9sbptd22ef?embedType=async&videoFoam=true&videoWidth=640

The Printer Shapes the Parts

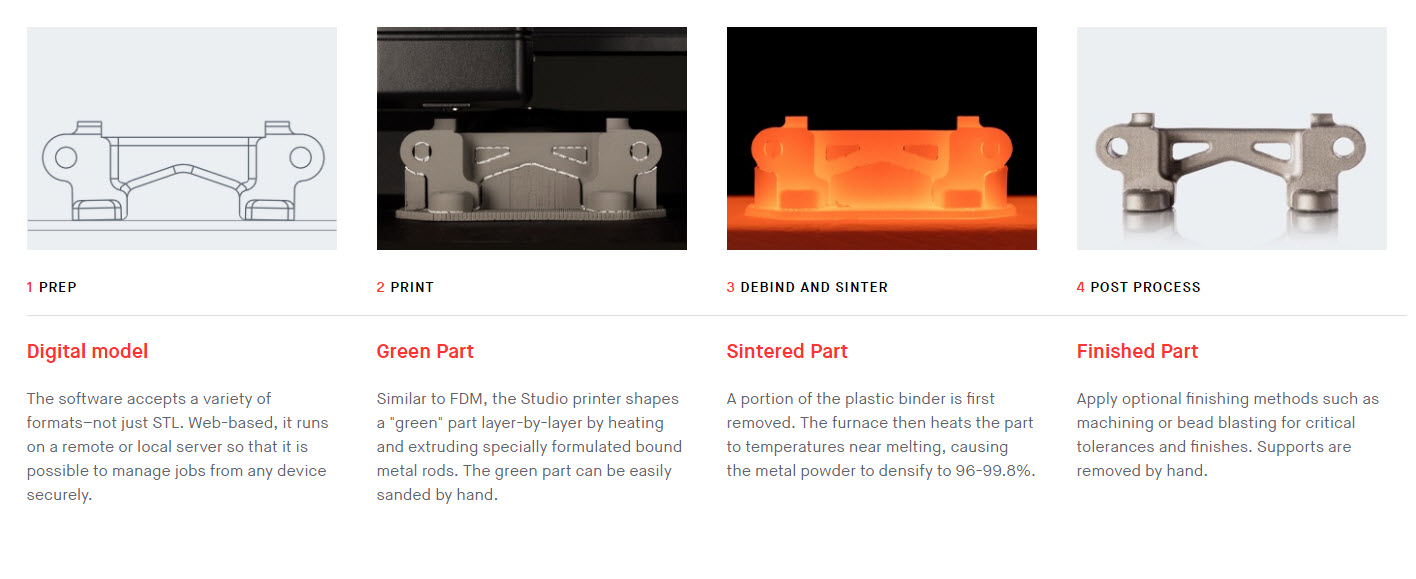

The Studio printer is similar to the safest and most widely used 3D printing process–Fused Deposition Modeling (FDM).

Unlike laser-based systems that selectively melt metal powder, the Studio printer extrudes bound metal rods–similar to how a plastic FDM printer works. This eliminates the safety requirements associated with metal 3D printing while opening up new alloys and enabling new features like the use of closed-cell infill for lightweight strength.

The Furnace Sinters the Parts

We designed the first office-friendly sintering furnace. Fully automated with closed loop thermal control and sized to fit through an office door, it delivers industrial-strength sintering in an office-friendly package.

How it Works

The furnace combines SiC heating elements with high-powered microwaves to sinter printed parts after primary binder is removed. Cloud-connected, the furnace has temperature profiles that are tuned to every build and material. It uniformly heats parts to just below their melting point, removing binder and fusing metal particles to form fully dense parts without the residual stresses introduced in laser-based systems.

The Process