GLOBAL LEADER IN ADDITIVE MANUFACTURING FINISHING SYSTEMS

DyeMansion is a Munich, Germany-based company offering finishing systems that turn 3D-printed raw parts into high-value products. With the ability to deliver precision coloring and high-quality finishes for even the most exact specifications, DyeMansion has quickly established itself as the global leader in additive manufacturing finishing systems for 3D-printed polymer parts. DyeMansion as a partner is already trusted by more than six hundred customers, including leading global manufacturers in diverse industries, such as eyewear, automotive, retail, medical and sports equipment.

DYEMANSION POWERSHOT C

BOOSTS YOUR PRODUCTION CAPACITY

With our proprietary PolyShot Cleaning (PSC) a mid-sized build job can be cleaned in only ten minutes or less. The time you need for part cleaning and the personnel in your production can be significantly reduced. This boosts your effectiveness and efficiency. By investing in automated part cleaning with the Powershot C, up to four manual blasting systems can be easily replaced. PolyShot Cleaning is compatible with all common powder-bed technologies and delivers residue-free parts for brilliant colors.

THANKS TO SMART HARDWARE FEATURES

The blasting cabinet of our Powershot C is equipped with a rotary basket and is manufactured from stainless steel. Different blasting nozzles and an ionization unit ensure reproducible results. Couple this with a basket with a soft and replaceable lining protecting the parts from damage during the process. Two simultaneously working blasting nozzles are positioned perpendicular to the rotating basket and the contained parts. The cyclone cleans the blasting media constantly. This configuration guarantees an efficient powder removal.

WITH ENHANCED ERGONOMICS AND PROCESS CONTROL

Experience a new level of process control with a touchscreen and integrated controlpanel. The Powershot C is being operated through a userfriendly interface and pre-installed programs can be started. Individual programs can be configured and saved easily, enabling a fast adaption to your application. With a user-centric design everything can be easily accessed and operated safely. Continuous monitoring allows an efficient and reproducible process.

DYEMANSION POWERSHOT S

TO ACHIEVE END-USE PARTS

Our proprietary PolyShot Surfacing (PSS) is non-abrasive and works perfectly for hard plastics like PA12 or PA11 across all geometries. Shooting beads accelerated with compressed air equalizes the peaks and lows of the surface, achieving a more homogenous part quality. With a cycle time of only 10 minutes and a capacity of a mid-sized build job per run, the Powershot S works very cost-effectively. Unlike timeconsuming abrasive methods like tumbling, PolyShot Surfacing increases your productivity and part quality significantly.

THE FOUNDATION FOR SUPERIOR COLORING RESULTS

We believe PolyShot Surfacing to be the main basis for maximizing coloring results. The Powershot S delivers unique semi-gloss looks and pleasant haptics for almost every 3D-printed end-use product. Being heavily used since 2016 in various industries, it set totally new quality standards due to enabling the results of improved scratch resistance and homogenous finishes. This is particularly important for further processing steps, like our DeepDye Coloring.

WITH ENHANCED ERGONOMICS AND PROCESS CONTROL

Experience a new level of process control with a touchscreen and integrated controlpanel. The Powershot S is being operated through a userfriendly interface and pre-installed programs can be started. Individual programs can be configured and saved easily, enabling a fast adaption to your application. With a user-centric design everything can be easily accessed and operated safely. Continuous monitoring allows an efficient and reproducible process.

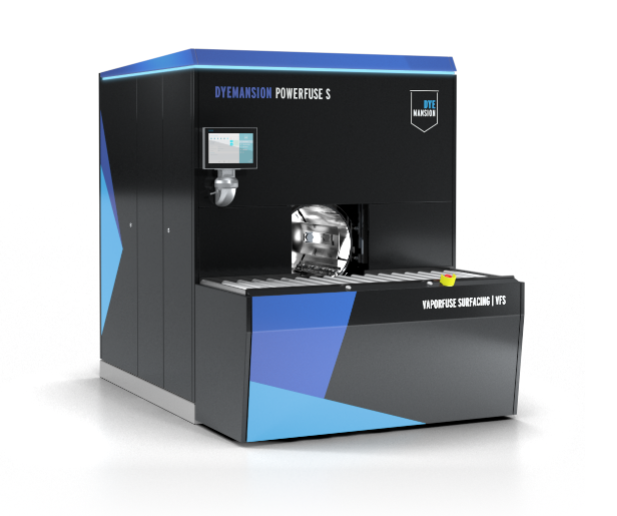

DYEMANSION POWERFUSE S

The VaporFuse Eco Fluid solvent is approved for the processing of plastics with food contact according to regulation (EU) 10/2011. The solvent is circulated continuously in a closed loop and automatically recovered by the system. This enables a sustainable contact-free process without chemical waste. Operating the Powerfuse S does not require protective clothing against chemical hazards.

VaporFuse Surfacing (VFS) delivers sealed and washable parts with injection molding like surfaces. The surface roughness is reduced to a minimum. The entire process chamber is flooded with vapor while undergoing vacuum. This ensures a reproducible processing of complex geometries and internal surfaces. VFS works for all common plastics and particularly for flexible polymers such as TPU, for which mechanical techniques are not suitable.

The Powerfuse S is Industry 4.0 ready. The system offers fully automatic loading, connectivity and batch tracking features. Validated and specially developed programs for all common materials are available and ready to use. In addition, all process parameters can be adapted individually for other materials. This ensures flexibility and a seamless integration with existing production processes such as the DyeMansion Print-to-Product workflow.

DM60

The innovative DeepDye Coloring (DDC) technology offers unlimited color choices. As a DM60 user you benefit from the largest color database. In addition to over 170 RAL and standardized colors, which are ready-to-use without additional development costs and waiting times, the color matching also offers the possibility of creating individual tones for you – from corporate colors to seasonal trend colors and individual skin tones. The fully automatic cleaning program of the DM60 allows a flexible use and a fast color change.

For a long time, dyeing 3D-printed plastics was a manual, uncontrollable process. Dyemansion takes care of this process and offers a global supply of exact color recipes down to the microgram. This enables an industrial process that could not be easier for the user and can be reproduced any time. The power lies in our color cartridges, which we manufacture depending on base material, finish and desired color. Based on the volume of your parts, they deliver cartridges in four different sizes. These are equipped with an RFID chip that transfers all process parameters QM ready to the DM60.

The demands for 3D-printed products are constantly increasing. These ISO-certified colors make Dyemansion a trusted technology partner for biocompatible eyewear or medical orthoses as well as for light- and heat-resistant automotive interiors. With their extended ColorsX line, they are responding to industry-specific requirements and are always looking forward to new input for the further development of their DeepDye Coloring (DDC) technology.

Please enter your Email address and Zip to Download the Dyemansion Powershot C PDF.

Please enter your Email address and Zip to Download the Dyemansion Powershot C PDF.