Form Auto

Realize the Benefits of High-Throughput 3D Printing

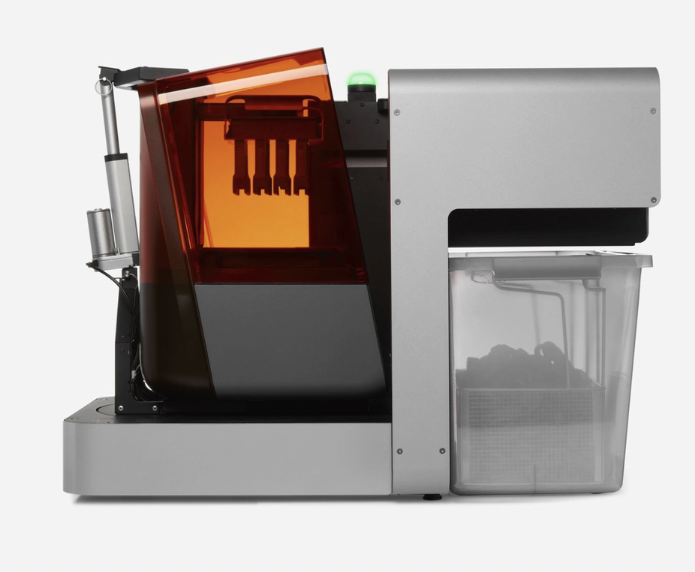

Form Auto is a hardware extension for Form 3/3+ 3D printers that automatically removes finished parts from Build Platform 2 and starts the next print without the need for operator interaction, enabling 24/7 3D printing with no printer downtime.

Skyrocket Your Ability to Produce High-Quality and Affordable Parts with Automated 24/7 3D Printing

Reduce cost per part with autonomous 24/7 printing on your Form 3/3+ 3D printer. Form Auto runs back-to-back prints which redefine your idea of throughput:

Start Scaling Your Production Now

Work more efficiently and redefine production capacity in your 3D printing workflow with Formlabs Automation Ecosystem including Form Auto, Fleet Control, and the High Volume Resin System.

Scale your part production without increasing printer management complexity. Hit send from anywhere and the Formlabs Automation Ecosystem will take care of the rest.

Minimize Cost Per Part with Labor Savings Up to 80%*

Form Auto works overtime so you don’t have to.

Before Form Auto, every completed part required manual removal from the build platform before post-processing. Form Auto fully automates part removal by leveraging Formlabs patented Quick Release Technology with Build Platform 2. Collected parts are placed in a UV-safe container for seamless batch transfer to the Form Wash.

Instantly automate your printers without additional training. Form Auto works with any Form 3/3+ 3D printer out in the field or purchased today, so you can level up your production at any time.

* Calculation based on dental arches printed in Draft Resin at 200µm.

24/7 3D Printing, With No Interaction Required

Never let a printer sit idle with prints waiting in the queue. Form Auto is always ready to start the next print with or without an operator on-site.

Build multi-print queues from anywhere, at any time. Click ‘Print’ from the office, and instantly start production on the manufacturing floor.

Monitor and review finished parts remotely via images and videos in Fleet Control. An onboard camera saves a record of each part by capturing each print as it completes.

Truly Rapid Production

Quickly go from design to finished part with the streamlined, end-to-end workflow of the Form 3+.

250mW

Laser Power

25-300μm

Layer Thickness

Rapid print speeds

A powerful, high-intensity laser and precisely tuned settings for every material deliver rapid print speeds.

Easy support removal

Enhanced light touch support structures detach from parts in seconds to save post-processing time.

An efficient ecosystem

Automated post-processing solutions simplify and streamline the entire 3D printing workflow.

Reliable, High-Quality Parts

The From 3+ refines Formlabs patented LFS technology to consistently deliver presentation-ready parts with unbelievable surface finish.

25μm

XY Resolution

85μm

Laser Spot Size

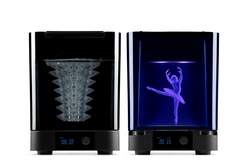

Crisp, Clean, Accurate Features

LFS technology accurately resolves fine features by delivering a clean, uniform laser spot across the entire print surface.

Production-Like Surface Finish

A flexible resin tank and refinements to the Light Processing Unit (LPU) create near perfect alignment between printed layers, giving parts a production-like finish.

Adaptive Layer Technology

Adaptive Layer Thickness automatically analyzes the geometry of parts and assigns layer heights throughout to maximize print speeds while preserving fine detail.

Maximum Efficiency

The Form 3+ is rich with features that improve ease of use so you can spend more time ideating and less time monitoring your printer.

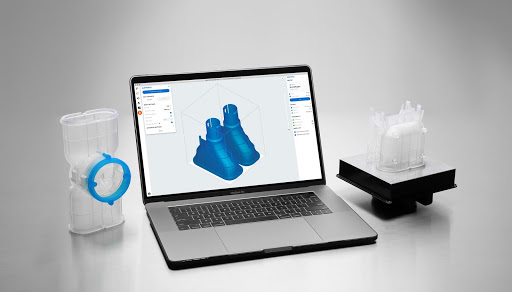

Print From Anywhere

Prepare your printer before you leave, then start jobs from anywhere with our cloud based Remote Print technology.

Minimal Printer Interactions

No specialized technicians required. Get started right away and let the printer do the work.

Hassle-Free Materials Management

Switch between a wide range of functional materials in seconds with our swappable resin cartridge and tank system. Form 3+ dispenses resin automatically as parts print.

Adaptive Layer Thickness automatically analyzes the geometry of parts and assigns layer heights throughout to maximize print speeds while preserving fine detail.

Wash and Cure Station