Standard Resins

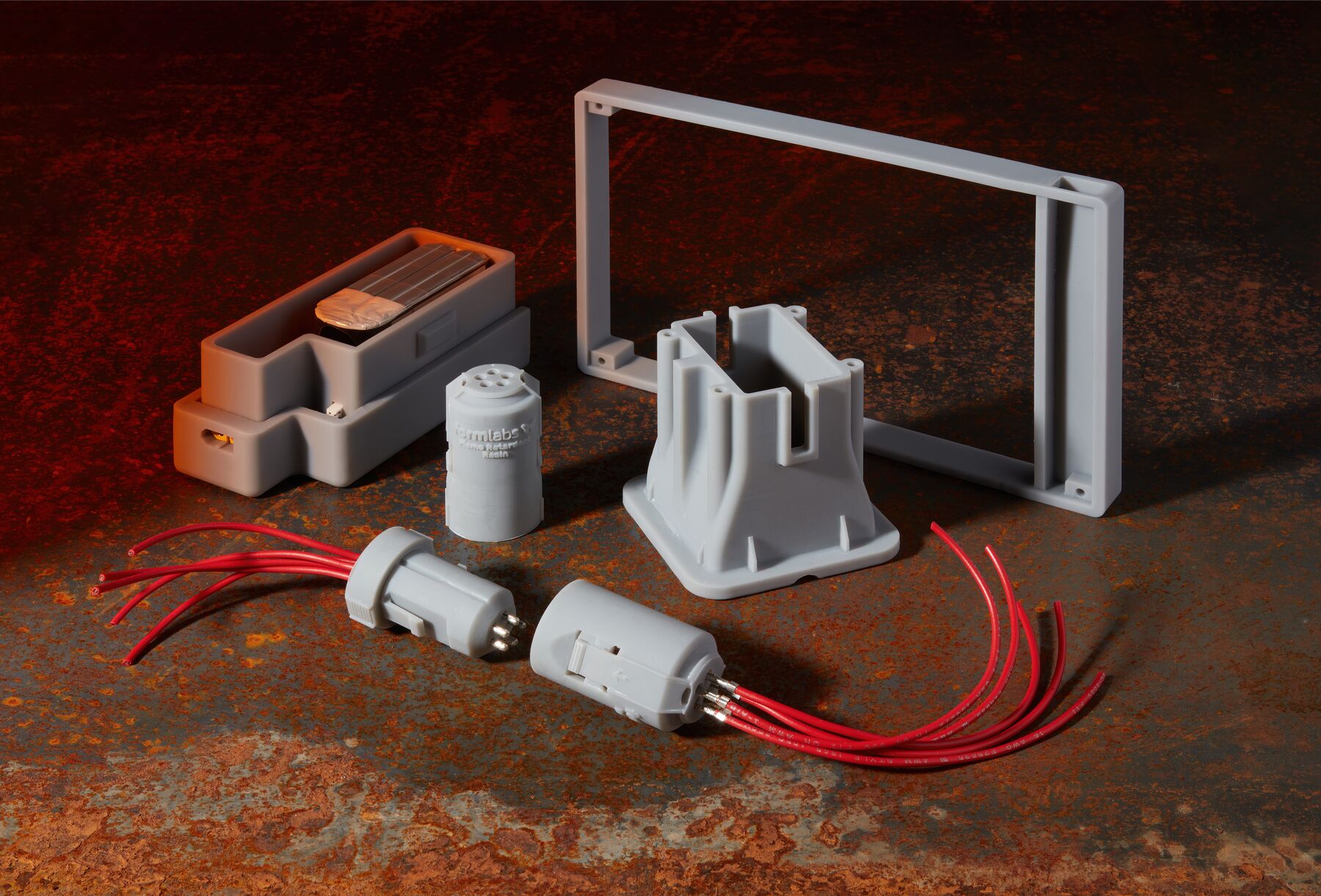

Grey Pro Resin for Prototypes & Models

With a matte surface finish, opaque appearance, and precise details, Black, White, and Grey Resins are ready to use right off the printer. Their neutral undertone also makes a great base for parts that will eventually be painted or undergo other finishing processes.

Clear Resin for Transparent Applications

Stereolithography 3D printing technology makes clear prints possible on the desktop. Clear Resin is great for fluidics and mold making, optics, lighting, and any parts requiring translucency.

Draft Resin for Truly Rapid Prototyping

Draft Resin prints up to four times faster than Formlabs standard materials, making it ideal for initial prototypes and rapid iterations to help bring products to market faster. Parts printed with Draft Resin exhibit a smooth grey finish and high accuracy. Use 200 micron settings for fast print speeds, or use 100 micron settings for models with finer details.

Standard Resins

- Gresycale Resins for Prototypes and Models: With a matte surface finish, opaque appearance, and precise details, Black, White, and Grey Resins are ready to use right off the printer. Their neutral undertone also makes a great base for parts that will eventually be painted or undergo other finishing processes.

- Clear Resin for Transparent Applications: Stereolithography 3D printing technology makes clear prints possible on the desktop. Clear Resin is great for fluidics and moldmaking, optics, lighting, and any parts requiring translucency.

- Color Resin: The first integrated color mixing solution for stereolithography, the Formlabs Color Kit enables 3D printing in 16 colors without the manual work of finishing and painting. Field test product concepts more quickly with 3D prints that fit their environment.

Engineering Resins

Grey Pro Resin for Versatile Prototyping

An Engineering Resin designed for high precision, moderate elongation, and low creep. Offering high precision, moderate elongation, and low creep.

- Concept Modeling

- Functional Prototyping

- Fit and Form testing

- Jigs and Fixtures

High Temp Resin for High Thermal Stability

High Temp is ideal for applications requiring the part to stand up to high temperatures with minimal loading. The material has almost no flex, however, so snap fits and living hinges are not suited for printing with High Temp Resin

- Hot air, gas, and fluid flow

- Heat resistant mounts, housings, and fixtures

- Molds and inserts

Rigid 4K for Stiff, Strong, Engineering-Grade Prototypes

Designed for stiffness and precision. The material is reinforced with glass to offer a very high modulus and a polished finish.

- Thin walls and features

- Turbines and fan blades

- Jigs, fixtures, and tools

- Manifolds

- Electrical casings and automotive housings

Rigid 10K – Rigid, Strong, Industrial-Grade Prototypes

Rigid 10K Resin offers high stiffness, strength, and resistance to heat and chemicals, making it a game-changing industrial material for the most demanding jobs. With a stiffness simulating that of glass and fiber-filled thermoplastics.

- Strong and stiff functional prototypes

- Temperature and chemical resistant prototypes

- High-temperature injection molding masters

- Stiff and strong aerodynamic test models

- Air and fluid flow components

Flexible 80A for Hard Flexible Prototypes

Flexible 80A Resin can withstand bending, flexing, and compression, even through repeated cycles. It is the most stiff soft-touch material in Flexible and Elastic Resins, with an 80A Shore durometer, balancing softness with strength

- Soft-touch, tactile prototypes

- Seals and gaskets

- Consumer products and wearables

- Medical devices and anatomical models

- Props and modelmaking

Elastic 50A for Soft Flexible Prototypes

An elastomeric material designed for applications requiring high elongation and high energy return. Use Elastic 50A Resin for parts that will bend, stretch, compress, and hold up to repeated cycles without tearing.

- Wearables and consumer goods prototyping

- Medical models and devices

- Compliant features for robotics

- Special effects props and models

Elastic Resin

- Our softest Engineering Resin, this 50A Shore durometer material is suitable for

prototyping parts normally produced with silicone. Choose Elastic Resin for parts

that will bend, stretch, compress, and hold up to repeated cycles without tearing. - Key applications include wearables and consumer goods prototyping; medical

visual simulation and devices; compliant features for robotics; and special effects

props and models. - Print resolutions: 100 microns only. Post-curing required. LT Tank Required.

Medical Resins

BioMed Amber Resin for Short-Term Bodily Contact

A stiff, functionally strong medical-grade material for biocompatible parts that require short-term skin and mucosal membrane contact.

BioMed Clear Resin for Long-Term Bodily Contact

A medical-grade material designed for rigid, non-brittle, biocompatible parts that require long-term skin and mucosal membrane contact and for end-use medical devices.

BioMed Durable Resin 1 L

BioMed Durable Resin is a clear 3D printing material for biocompatible applications requiring impact, shatter, and abrasion resistance. This USP Class VI material can be used in applications for long-term skin and short-term tissue, bone, and dentin contact (<24 hours).

Jewelry Resins

- Castable Resin was designed to capture precise details and smooth surfaces.

- It burns out cleanly without ash or residue, allowing jewelers and casting houses to go straight from digital design to a 3D print suitable for direct investment casting.

Flame Retardant Resin 1Kg (0.84L)

Drive innovation more quickly, safely, and efficiently with Formlabs’ new self-extinguishing and halogen-free SLA material with a UL 94 V-0 certification and favorable flame, smoke, and toxicity (FST) ratings.Use FR Resin to easily 3D print flame retardant, heat-resistant, stiff, and creep-resistant parts that will perform well long-term in indoor and industrial environments with high

temperatures or ignition sources.

Compatibility

● Printer compatibility: Form 2, Form 3, Form 3B, Form 3L, Form 3BL, Form 3+, Form 3B+

● Compatible with these resin tanks: Form 2 Resin Tank (PDMS), Form 2 LT Tank, Form 3/3B Resin Tank V1, Form 3/3B Resin Tank V2, Form 3/3B Resin Tank V2.1, Form 3L/3BL Resin Tank V1

● Compatible with these build platforms: Form 3 Build Platform 2

Build Platform 2L

Build Platform 2L with patented Quick Release Technology allows you to quickly and

easily remove 3D printed parts from the build platform without tools in seconds.

Streamline your post-processing workflow with instant and flawless part removals.

Compatibility

● Printer compatibility: Form 3L, Form 3BL