Post-Processing 3D Printed Parts

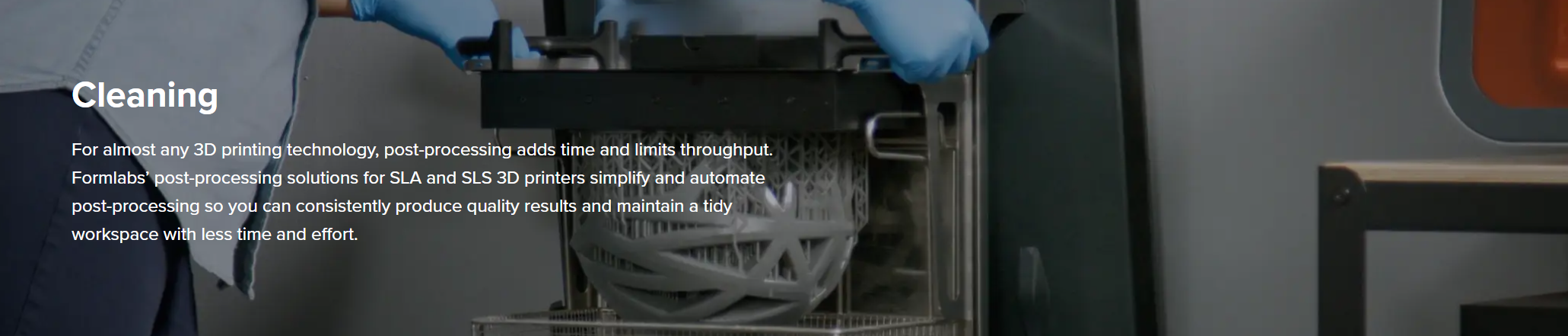

Post-processing 3D printed parts is essential to achieve the optimal finish and performance, while advanced post-processing methods empower you to improve aesthetics, mechanical properties, and overall performance to make your parts suitable for a wide range of applications.

Post Processing for Resin Printers

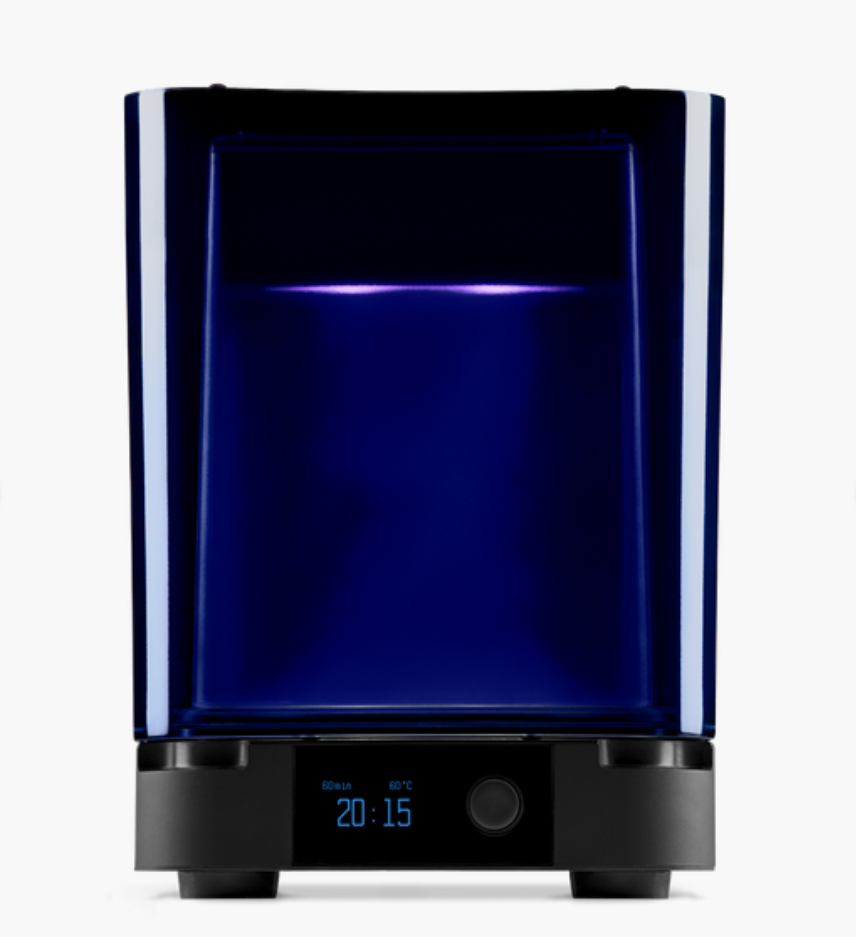

Adaptable to Build Platforms

Seamlessly switch between build platforms with adjustable platform mounts, configurable at various heights and widths.

Flexible Solvent Volume

Tailor the solvent volume to the size and quantity of your parts. Use lower solvent quantities for smaller parts and builds to increase resource efficiency.

Improved Agitation

Let Form Wash auto-clean your parts for the appropriate time thoroughly with 3x more agitation than the previous generation.

Compatible with Variety of Solvents

Our recommendation is using IPA for the best cleaning performance, but alternative solvents such as TPM are also compatible with Form Wash.

Form Cure

Form Cure L

Formlabs Resin Washing Solution

Formlabs Resin Washing Solution is a non-flammable* solution for cleaning resin off of 3D printed parts. This solution cleans as well as IPA, but can dissolve twice as much resin before becoming saturated. Reduce wash replenishing and cost per washed part with a part-cleaning solution safe enough for any workspace.

Formlabs Resin Washing Solution is recommended with the Form Wash (2nd Generation) and Form Wash L.

Post Processing for Powder Printers

Fuse Sift

All-in-one powder recycling and recovery.

Our all-in-one powder recovery station, Fuse Sift, combines part extraction, powder recovery, storage, and mixing in a single device.

Produce fully-functional parts with competitively high powder recyclability to enable less waste and lower cost per part.

Fuse Sift will dispense and mix used and new powder automatically so you can reduce waste and control your powder supply.

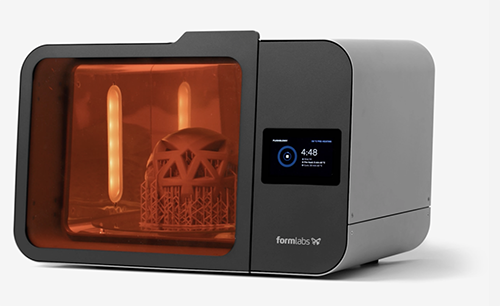

Fuse Blast

Achieve professional, consistent parts that are clean to the touch faster and easier than ever before with Fuse Blast, an easy-to-use, fully automated cleaning and polishing solution for post-processing SLS 3D printed parts.

Why Choose the Fuse Blast

Fuse Blast delivers 100% hands-off cleaning and polishing for SLS parts.

Finished Parts In 15 Minutes

Cleaning routines automatically post-process an entire build chamber in as little as 15 minutes, while the passive filtering reduces media saturation and extends media life to save on overhead costs.

Consistent Results

Pre-programmed routines take out the guesswork for consistent results, while manual mode allows you to adapt to any part requirements.

Professional Parts

Deliver clean-to-the-touch parts thanks to the in-line ionizer that prevents dust and media from re-settling on your parts, or go the extra mile with the optional polishing function for a smooth, semi-gloss, and dye-ready surface finish.

Streamlined Post-Processing

Fuse Blast seamlessly integrates into the Fuse ecosystem for an automated post-processing workflow that reduces labor time by 80% and delivers finished parts in as little as 15 minutes.

Fuse Blast Polishing System

The Fuse Blast Polishing System is a drop-in upgrade to the Fuse Blast that allows users to add a smooth, semi-gloss, scuff-resistant, and dye-ready surface finish to their SLS printed parts. With the Polishing System, users can create parts for consumer-facing, end-use applications with improved feel and appearance.