reprint from https://3dprintingindustry.com/

The Indian Navy has partnered with Indian 3D printing service bureau think3D to help produce spare parts on-demand using additive manufacturing, for both on and off-shore scenarios.

The availability of spare parts has been a recurring problem for the Indian Navy due to the use of old, imported machinery. Collaborating with think3D, the Indian Navy has sought to solve this problem by instead 3D printing spare parts and replacing them on demand. think3D has supplied various 3D Printed spare parts to Indian Navy, all of which have been successfully tested and incorporated into its machinery. One particular case study that the company has shared revolves around the replacement of centrifugal pump impellers, key components for a ship’s operation, using 3D printing.

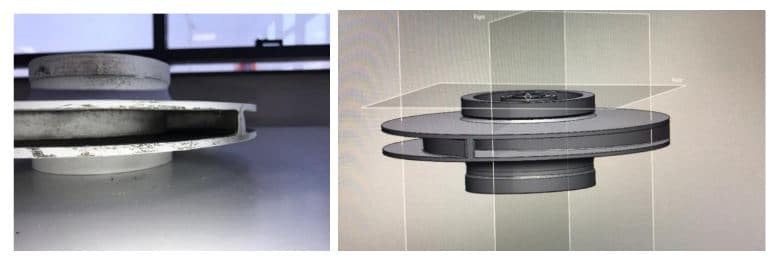

The centrifugal pump impeller onboard Navy ships. Photo via think3D.

The difficulty of sourcing spare parts for old machinery

A large proportion of the machines present on the Navy’s ships are very old and imported from other countries. As such, sourcing spare parts for these machines whenever a component gets damaged can be a long process, with significant delays before a part is received. This can prove costly for the Navy as it keeps its machines idle before the spare parts get replaced. One such example arrives in the Navy’s long-pending need for a quick replacement of centrifugal pump impellers onboard its ships.

The impeller is a rotating component of a centrifugal pump. It is responsible for transferring energy from the motor to the fluid being pumped by accelerating the fluid outwards from the center of rotation. On ships, it is used to import seawater to sections of the ship for regular water needs. Impellers often come in different shapes and sizes according to the amount of liquid to be pumped. They are required to rotate at high speeds for long periods of time.

The breakdown of these impellers has caused major problems for the Indian Navy. These breakdowns are most often caused by the displacement of the eye of the impeller during rotation and by foreign particles in the sea hitting the impeller. As the impellers rotate at high speeds, the aforementioned problems are common occurrences. Replacement parts for these impellers involve a sand casting manufacturing process which often necessitates a 3 month turn-around time to produce a new impeller. Each ship has multiple such pumps and impellers and constant breakdowns have caused a major impediment to the Indian Navy in carrying out its regular tasks.

Seeking an alternative manufacturing process where these impellers can be produced quickly and at a lower cost of ownership, the Indian Navy identified 3D printing as a possible solution and contacted think3D.

Reverse engineering and 3D printing the impeller

Founded in 2014, think3D aims to increase the market awareness of 3D printing and its potential applications in India. The company offers services for 3D printing, design, scanning and batch production with other manufacturing processes as well. It also operates a $6 million 3D printing facility for medical device manufacturing in the AP MedTech Zone, a manufacturing park for medical equipment in the Indian state of Andhra Pradesh.

After being contacted by the Indian Navy, the think3D team visited the ships to understand the problem in detail and to collect data on the impellers, including material properties required and boundary conditions. Its first step involved 3D scanning the impeller and reverse engineering its design. This was performed using an EinScan Pro+ 3D Scanner and CREO to create the CAD model based on the scanned data. Using ANSYS software, think3D then investigated which material and 3D printing process would benefit the application. Various materials like nylon composites, glass-filled nylon, PA12, other regular plastics were tested for suitability.

Reverse engineering the impeller. Photo via think3D.

An important requirement for the impeller material was its damping capabilities, which refers to its ability to convert vibrational energy into other forms of energy without the part breaking apart. Additionally, the part was required to have enough elasticity to withstand the vibrations as well. This ruled out various high strength materials as they were highly brittle, with think3D identifying a material with good damping property and elasticity for the final part. think3D has opted to keep the specific material used confidential.

Using Multi Jet Fusion technology from HP, think3D 3D printed the impeller with the desired mechanical properties. It was then CNC machined with metal bushings inserted to create an interface between metal rod and plastic component, required for rotating the impeller without the part breaking. After being tested aboard the ship, the impeller demonstrated an adequate performance for the desired number of hours. A part that would take 3 months to manufacture has instead taken 2 days to manufacture using 3D printing, while the cost of producing the component was 40 percent lower according to think3D. The 3D printed impeller was also lower in weight, coming in at 1kg compared to traditionally manufactured impellers which weigh between 8 kg and 9 kg.

With the successful completion of the 3D Printed impeller, think3D has now set its sights on building a digital repository of impellers for the Indian Navy. Once the repository is built, the company has committed to 3D printing the required impellers on demand to supply to the Navy.

The original impeller part (left), next to the 3D printed version (right). Photo via think3D.

Additionally, think3D has also detailed how it has collaborated with the Indian Navy to deliberate an approach for having a 3D printer mounted onboard a ship for when spare parts are needed on demand off-shore, with the CAD designs of the spare parts pre-loaded into the machine. In most cases, this would require the Indian Navy to air-lift parts to the ship or bring the ship back to shore for fitting the components, both of which come at significant cost. think3D is therefore building a customized 3D printer for the Indian Navy capable of additive manufacturing in off-shore conditions.

For more information on HP Jet Fusion Technology, please click the button below.

Leave A Comment