Modeling from a 2D Drawing with Design X Go

Let’s explore some of the CAD modeling capabilities of Design X Go without the need for a scan, and how you can open the created model in Mastercam for toolpath generation.

Unlocking CAD Modeling Potential

When you have something like a 2D Print or a DXF file of a part, Design X Go enables you to transform these into a 3D model suitable for CNC programming using Mastercam’s dynamic tool pathing capabilities.

Creating and Constraining Sketches

Design X Go allows you to create base sketches, apply dimensional constraints, and use profile offsetting to form complex shapes. You can easily manage constraints to simplify your sketches and ensure accuracy.

Utilizing Existing Geometry

With tools like Convert Entities, you can leverage previously created geometry to build new sketch entities, streamlining the modeling process and ensuring consistency across your design.

Modeling Complex Features

Design X Go supports the creation of intricate features such as stepped pockets and filleted corners. By using a combination of lines, trimming, and dimensional constraints, you can accurately model detailed parts.

Extruding and Finalizing the Model

Once your sketches are complete, Design X Go provides robust extrusion capabilities to form the main base plate and any additional features. You can extrude profiles to specific dimensions, creating both simple and complex geometries.

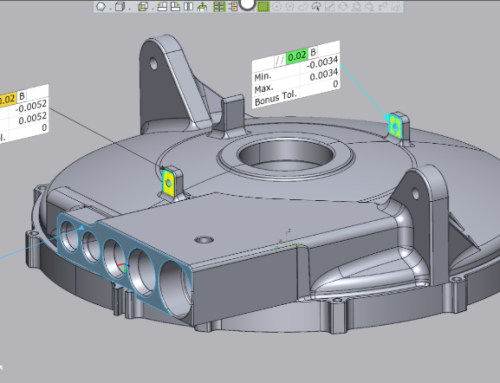

Seamless Integration with Mastercam

After modeling, the solid model can be exported into Mastercam. Here, Dynamic tool pathing automates the machining process, ensuring efficient and precise CNC programming.

Conclusion

Even with just a 2D drawing, Design X Go empowers users to create detailed 3D models that can be seamlessly integrated into Mastercam for advanced machining. This capability enhances productivity and precision in manufacturing workflows.

Leave A Comment