Ultrafast Photoplastics for Rapid Prototyping

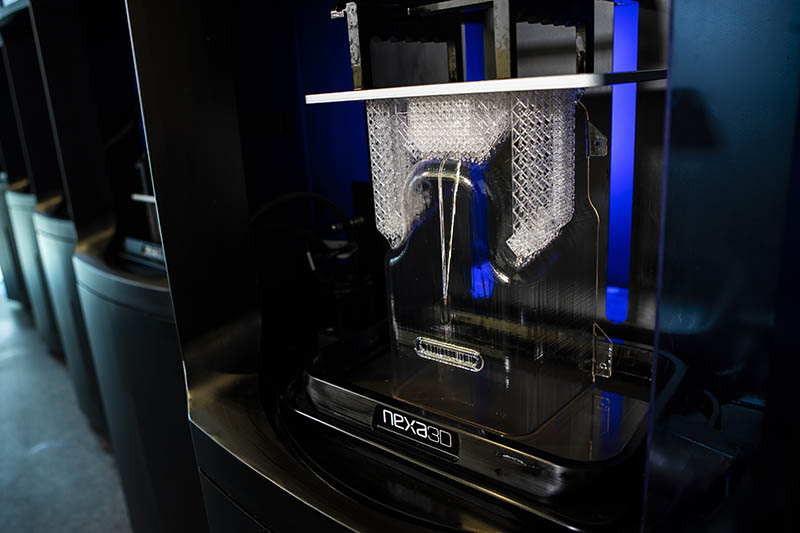

Nexa3D, the maker of ultrafast stereolithography production 3D printers, recently announced that it has expanded its partnership with BASF Forward AM to deliver three new ultrafast photopolymer materials through its expanding Nexa3D channels globally. Nexa3D’s collaboration with BASF Forward AM leverages their combined capabilities to deliver faster additive-manufactured prototypes across multiple industries, leveraging the 20X productivity advantage of its ultrafast NXE 400 3D printer. No other manufacturing process offers as many possibilities for greater design agility, supply chain resiliency and rapid implementation at every phase of the product lifecycle. Combining Nexa3D’s productivity with Forward AM’s rapidly expanding suite of tailor-made photopolymer formulations makes it possible for customers to rapidly design a wider range of parts such as housings, enclosures, pipes, packaging products, and footwear components with greater performance and functionality.

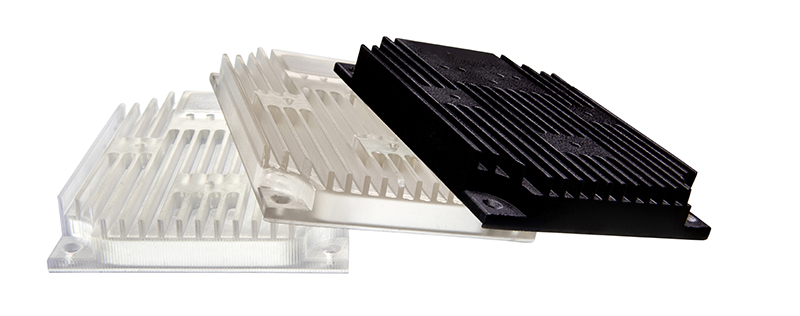

x45-NATURAL is a tough material that is ideal for models and functional prototypes requiring high strength and durability. Capable of much higher print speeds than current materials, x45-NATURAL features excellent out-of-printer properties with robust print styles to ensure high first-time build success. Supporting a wide variety of applications with short processing times, x45-NATURAL’s draft build mode enables companies greater flexibility within their manufacturing processes. To learn more about x45-NATURAL, check out this video and the Nexa3D materials page.

x45-CLEAR combines good clarity with toughness for a wide variety of models and functional prototypes requiring fast turnaround times. x45-CLEAR has outstanding build speed to give companies greater adaptability within their manufacturing processes. x45-CLEAR has excellent out-of-printer properties with robust print styles to ensure high first-time build success. To learn more about x45-CLEAR, check out this video and the Nexa3D materials page.

x45-BLACK is a durable material that features an attractive matte black finish for parts such as automotive components that are usually molded in black plastic. It combines build speed and excellent out-of-printer properties to ensure first-time build success, giving manufacturers greater flexibility within their output processes. To learn more about x45-BLACK, check out this video and the Nexa3D materials page.

“Thanks to these new BASF materials and Nexa3D’s open materials platform, fast just got faster,” said Kevin McAlea, COO, Nexa3D. “Both companies are committed to democratizing access to scalable additive polymer solutions for the entire product life cycle from design to production. With NXE400’s 20X productivity gains and up to 85% lower total cost of ownership, manufacturers will benefit from higher productivity, better functionality and exceptional cost effectiveness.”

View all the Nexa3D materials by clicking below.

Leave A Comment