Healthcare providers use 3D printing to enhance training, optimize pre-surgical prep, and create personalized tools. TTSH uses versatile resins for realistic prostheses.

Transforming Patient Care at Tan Tock Seng Hospital’s Medical 3D Printing Centre

Emergency surgeries need swift responses, making third-party vendors impractical. TTSH established an in-house 3D printing lab for timely, accurate solutions.

The Centre, operational since 2020 and launched in 2022, 3D prints organ models for clearer medical explanations and surgical tools for practice. It uses Formlabs’ Form 3B+ and Form 3BL printers with biocompatible materials.

The Challenge

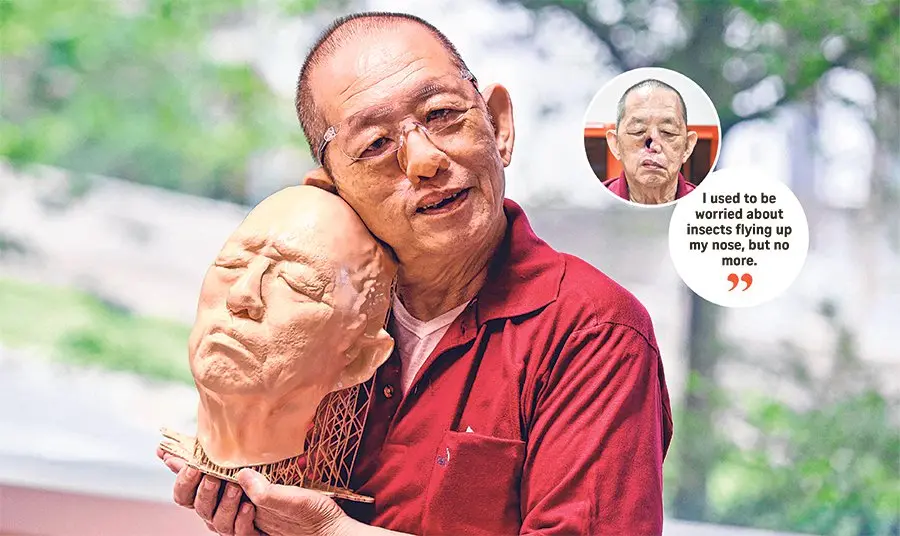

In 2022, 73-year-old J. F. Lian, battling skin cancer, had most of his nose removed. TTSH offered him a 3D printed nose, identical to the original, as a pilot project.

Skin cancer survivor Mr. J. F. Lian with his 3D printed face model and prosthetic nose.

The Solution

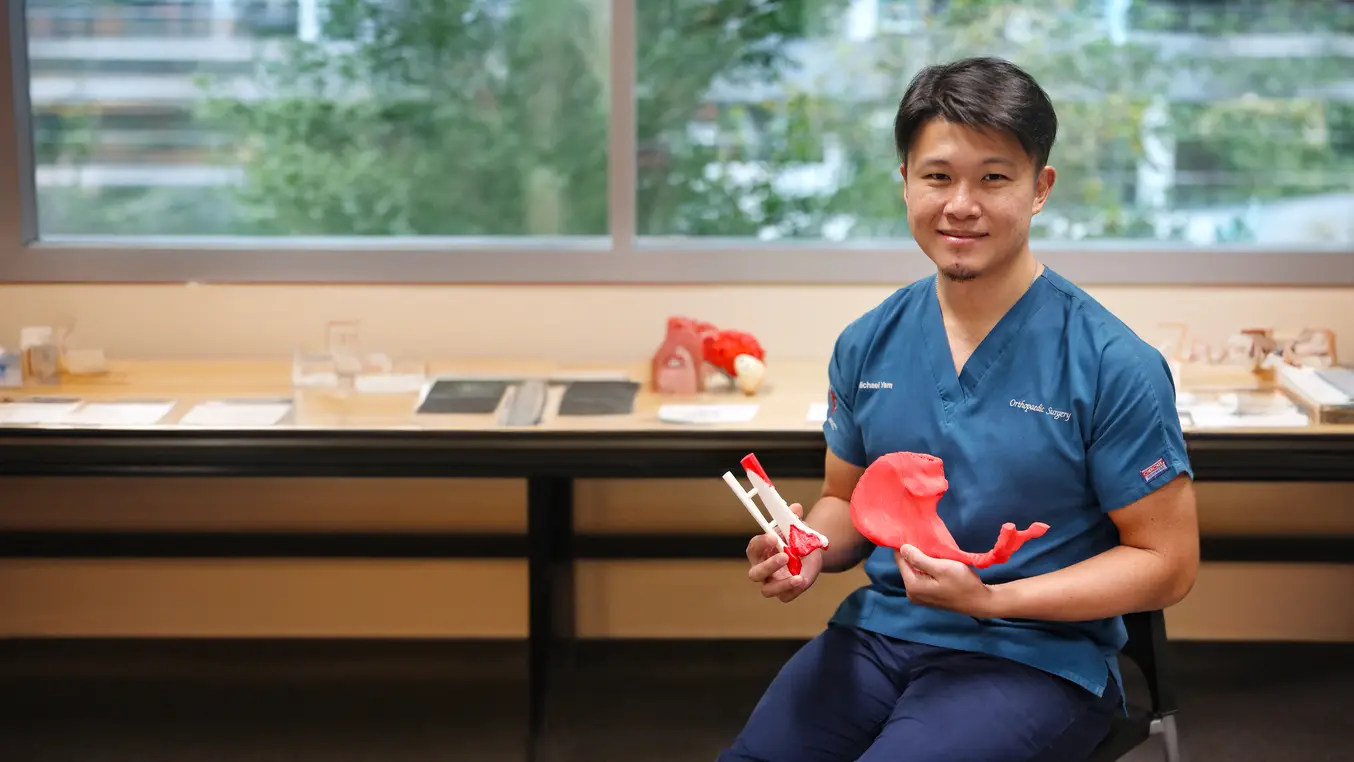

A colleague suggested 3D printing a prosthetic nose for Lian. Dr. Yam, always pushing boundaries, agreed. In November 2022, TTSH custom-designed and printed a resin nose based on Lian’s face scans. The process involved creating a 3D print file from CT scans, printing, cleaning, curing, and finishing the model. Dr. Yam aims to make 3D printing more accessible to patients.

Testing of the 3D printed nose prosthetic on Mr. Lian.

The Outcome

Creating Mr. Lian’s 3D printed prosthetic nose began with CT scans. After initial fitting issues, new scans were taken. Dr. Yam collaborated with cosmetic experts to match skin tones, requiring significant experimentation. Transparent tape and glasses helped secure the prosthesis comfortably.

Dr. Michael Yam, head of the TTSH 3D printing team, first used 3D printing to assist in surgery in 2019.

Accurate Results via Surgical Guides

Dr. Yam shared that Formlabs’ 3D printing technology is used for surgical guides, improving results, accuracy, and saving time. In a recent case, a custom 3D printed jig helped precisely fit a bone graft for a man with a femur defect, reducing surgery and anesthesia time, and potentially lowering infection rates.

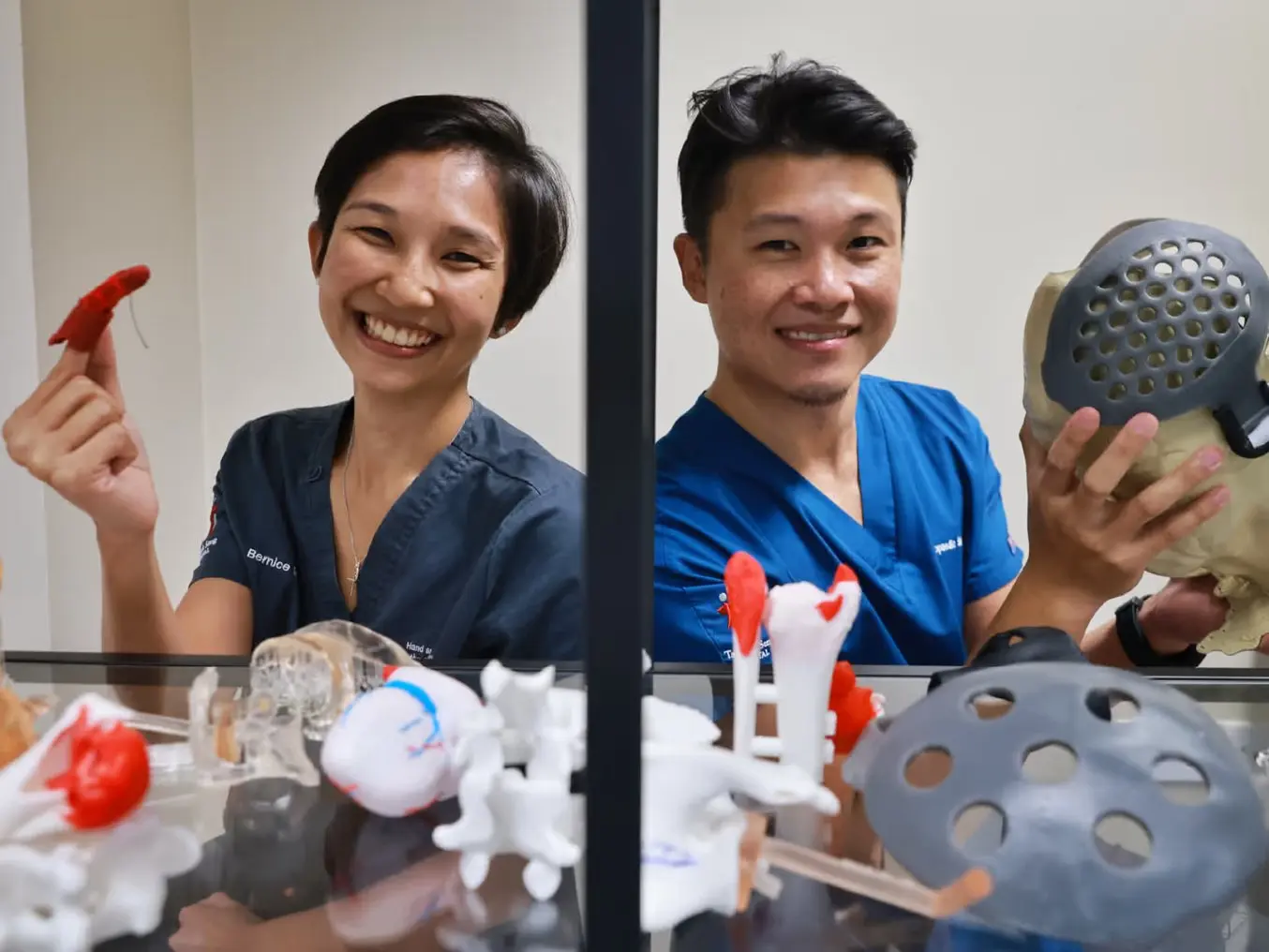

Examples of patient-specific surgical guides and 3D models printed by TTSH, achieving remarkable accuracy and efficiency in numerous operations.

Future 3D Printing Projects

TTSH is working on implantable printing using materials like titanium, stainless steel, PEEK, and silicone resin. They are also combining augmented reality with 3D printing for teaching. TTSH aims to produce customized prosthetics and surgical guides, enhancing accuracy and patient care. As you can see, solutions can be reached by scanning for 3D printed prosthetics. Contact us to learn more about transforming patient care!

Leave A Comment